Table of Contents

- 1.0Aluminum Tube and Profile Bending: Benefits, Shapes, and Processing Techniques

- 2.0Common Surface Treatment Processes for Aluminum Tubes

- 3.0Comparison of Aluminum Tube Bending Tools and Methods

- 4.0Manual Pipe Bending – Step-by-Step Process

- 5.0Common Aluminum Alloys by Series: Properties and Applications

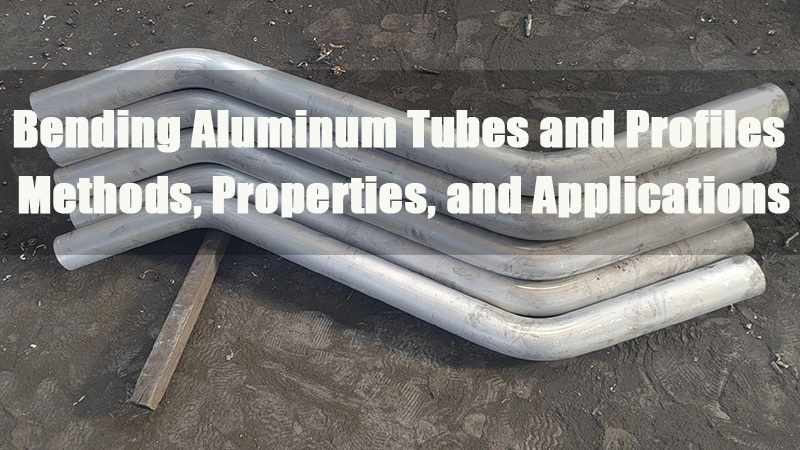

1.0Aluminum Tube and Profile Bending: Benefits, Shapes, and Processing Techniques

Aluminum has become the preferred material in many industries due to its lightweight nature, excellent corrosion resistance, and superior formability. When it comes to bending aluminum tubes and profiles, the advantages are numerous—not only in performance but also in design flexibility and processing efficiency.

1.1Advantages of Bending Aluminum Tubes and Profiles

- Lightweight: Aluminum significantly reduces weight compared to steel, ideal for structural and mobile applications.

- Corrosion Resistance: Natural oxide layer offers protection; can be enhanced via anodizing or other surface treatments.

- Good Thermal Conductivity: Suitable for heat dissipation applications like heat sinks and LED fixtures.

- Aesthetic Appearance: Smooth surface finish, easily processed for decorative applications.

- High Ductility: Aluminum profiles can be bent, drilled, and milled without cracking—great for complex geometries.

- Processing Flexibility: Excellent formability, adapts to various manufacturing needs.

- Hollow Structure: Aluminum tubes are lighter due to internal voids, suitable for automotive, furniture, and architectural applications.

- Controlled Cold Bending: Requires proper alloy temper selection and bend radius control to avoid cracking and ensure quality.

1.2Common Cross-Sectional Shapes of Aluminum Profiles and Tubes

| Cross-Section Type | Description | Example Applications |

| Round | Most common and simple structure, uniform pressure distribution | Beverage cans, food cans, chemical containers |

| Oval | Between round and flat, suitable for space-limited scenarios | Specialized packaging, portable containers |

| Square | Defined corners, high space utilization | Transport tanks, storage tanks, and special industrial containers |

| Rectangular | Like square but with unequal sides | Containers, shipping boxes, industrial tanks |

| Polygonal | Multiple sides, various shapes | Stylish packaging cans, function-specific containers |

| Irregular (Custom) | Non-standard shapes for special design needs | Custom aluminum cans, e.g., heart-shaped, star-shaped |

1.3Pre – and Post-Bending Processing of Aluminum Tubes

| Stage | Common Processes | Key Considerations |

| Before Bending | Laser cutting, drilling, countersinking, angle cutting, and marking | Avoid processing near bending deformation zones |

| After Bending | Trimming, tapping, milling, crimping, etc. | Maintain the integrity and appearance of the bent section |

2.0Common Surface Treatment Processes for Aluminum Tubes

- Anodizing: Enhances corrosion and wear resistance; allows for decorative coloring.

- Spray Coating: Applies protective or decorative layers; available in various colors and is printable.

- Electrophoretic Coating: Uniform and eco-friendly coating with good corrosion resistance.

- Brushing: Produces fine surface textures for improved visual and tactile appeal.

- Polishing: Creates a smooth and glossy surface finish for enhanced aesthetics.

- Silk Screening: Prints text or patterns directly; suitable for mass production with clear designs.

- Laser Engraving: Permanent, precise marking for patterns or anti-counterfeit labels.

- Sandblasting: Produces matte or frosted textures; increases friction and decorative effect.

- Electroplating: Applies a metallic layer for added hardness and decorative value.

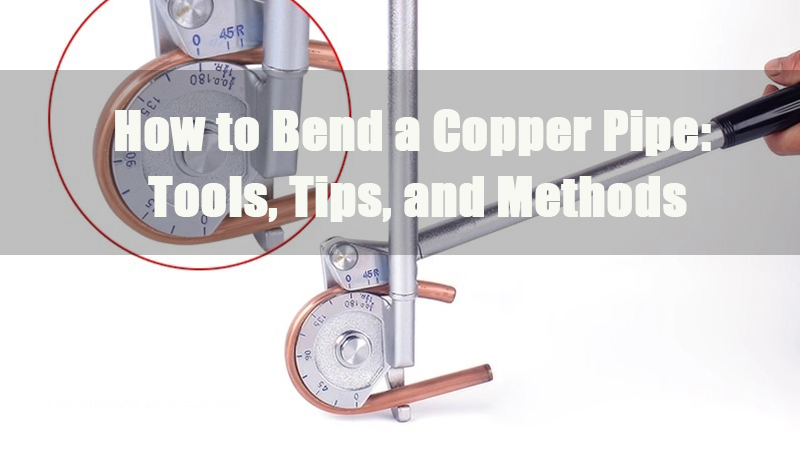

3.0Comparison of Aluminum Tube Bending Tools and Methods

| Method | Brief Description | Common Equipment |

| Mechanical Bending (Cold Bending) | Bending at room temperature using mechanical force; suitable for thin-walled tubes and standard curves | Manual Pipe Bender, Hydraulic Pipe Bender, CNC Pipe Bender |

| Hot Bending | Heating the tube before bending to reduce fracture risk; suitable for less ductile materials | Hot Bending Machine, Heated Pipe Bender |

| Rotary Draw Bending | Continuous forming via rotating dies; ideal for high precision and complex curves | Rotary Draw Bender, CNC Pipe Bender |

| Compression Bending | Direct force applied via pressing die; suitable for thick-wall or small-radius tubes | Compression Bender, Hydraulic Press |

| Hydraulic Bending | Uses hydraulic pressure for high force applications; ideal for large diameter or high-strength tubes | Hydraulic Tube Bender, Hydraulic Press Bender |

| Stretch Bending | Material is stretched during bending to prevent wrinkling; ideal for high visual quality | Stretch Bender, CNC Stretch Bender |

| Roll Bending | Gradual forming with multiple rollers; used for large-radius and long tube bending | Roll Bender, Three-Roller Bending Machine |

| Die Bending | Uses custom dies for precise angles and shapes; ideal for mass production | Die Bender, CNC Bender, Manual Die Fixtures |

Conclusion:In industrial applications, pipe benders are the most effective tools for aluminum tube bending, ensuring a balance of efficiency, safety, and quality.

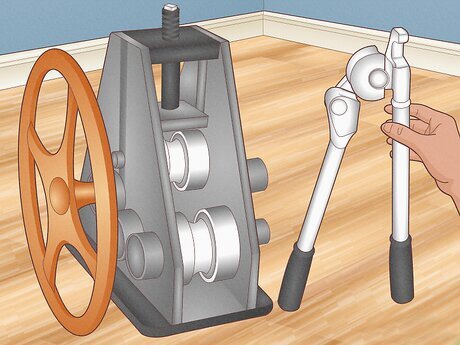

4.0Manual Pipe Bending – Step-by-Step Process

4.1Step 1: Choose the Bending Tool

Use a manual or hydraulic pipe bender. For 1¼ inch (~3.7 cm) aluminum conduit, a manual bender is more convenient. The key is to prevent collapse during bending, not just choosing the tool.

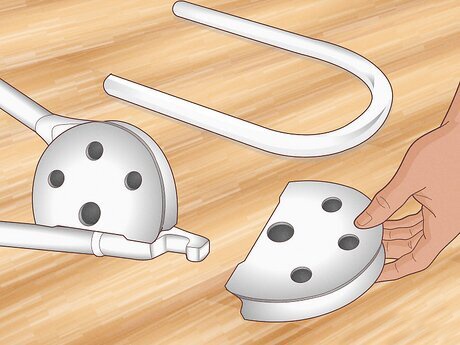

4.2Step 2: Fill the Tube

Fill the tube with sand or other packing material. Wrap the ends with triple-layer window mesh and secure both ends with dual hose clamps to prevent leakage.

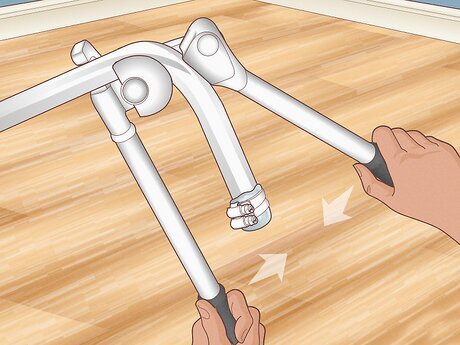

4.3Step 3: Bend Slowly

Bend the tube slowly and evenly. Avoid collapse or deformation. Watch closely for cracks and do not overbend.

4.4Step 4: Apply Suitable Methods

Use any applicable bending method, as long as the tube remains intact. Follow the general guideline: bend radius should be at least 3.5 times the tube diameter (~8.8 cm minimum for 1-inch tube).

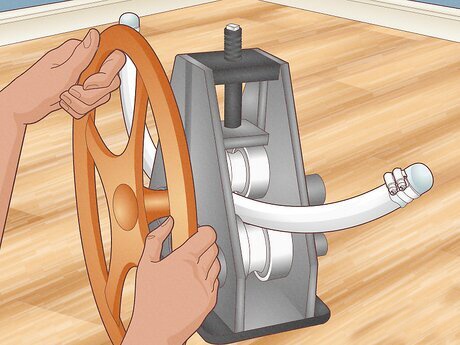

4.5Step 5: Use a Die (Optional)

If available, consider using manual or hydraulic benders with matching dies to achieve more precise and repeatable bends.

5.0Common Aluminum Alloys by Series: Properties and Applications

| Series | Primary Alloying Element | Key Properties | Typical Applications |

| 1000 Series | None (Pure Aluminum) | Low mechanical strength, excellent thermal and electrical conductivity, superb corrosion resistance | Heat exchangers, electrical condensers, packaging, signage, food industry |

| 2000 Series | Copper (Al-Cu) | High strength, relatively poor corrosion resistance | Military applications, injection molds, precision tools |

| 3000 Series | Manganese (Al-Mn) | High strength, low ductility, good corrosion resistance | Home appliances, transportation equipment |

| 4000 Series | Silicon (Al-Si) | Excellent wear resistance, low thermal expansion coefficient | Welding applications |

| 5000 Series | Magnesium (Al-Mg) | Good ductility, excellent corrosion resistance, great weldability | Shipbuilding, naval vessels, automotive body parts |

| 6000 Series | Magnesium + Silicon (Al-Mg-Si) | Excellent mechanical properties, heat-treatable, suitable for bending, strong weldability. Alloy 6060 is a top choice for tube bending. | Furniture, shipbuilding, lighting, rail transit, automotive components |

| 7000 Series | Zinc (Zn) | Very high strength and hardness after heat treatment, superior mechanical performance | Motorcycle and bicycle frames, other transportation parts |

| 8000 Series | Mixed Alloys | Low density, high strength, good low-temperature toughness | Aerospace industry |