The AEK-PTG Pipe Grooving Machine is a high-precision hydraulic device engineered for reliable, efficient pipe-end grooving. Equipped with a microcomputer control system, it integrates start/reset, emergency stop functions, and multiple safety protections to ensure safe, stable, automated operation.

Applications:

- Automotive & Mechanical Manufacturing: Engine parts, crankshafts, camshafts, and other precision components.

- Aerospace & High-Precision Industries: Critical pipe end forming with strict tolerances.

- Medical Devices: Forming of artificial joint components and other high-precision parts.

- Fire Protection & Plumbing: Standpipes, drain pipes, sprinkler systems, and other industrial piping.

Working Principle

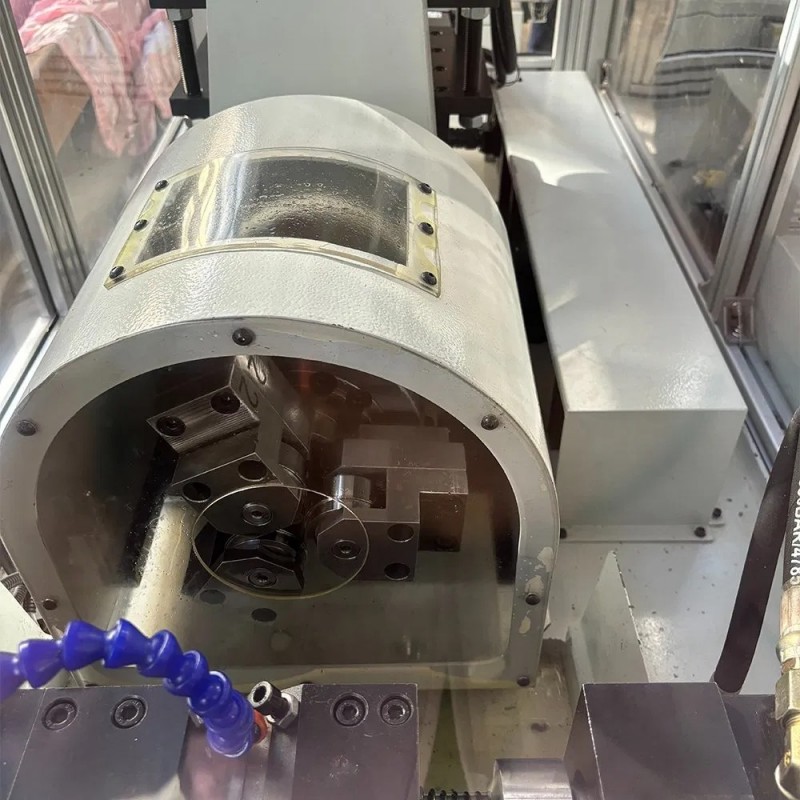

- The pipe is clamped on the worktable or a rotating spindle.

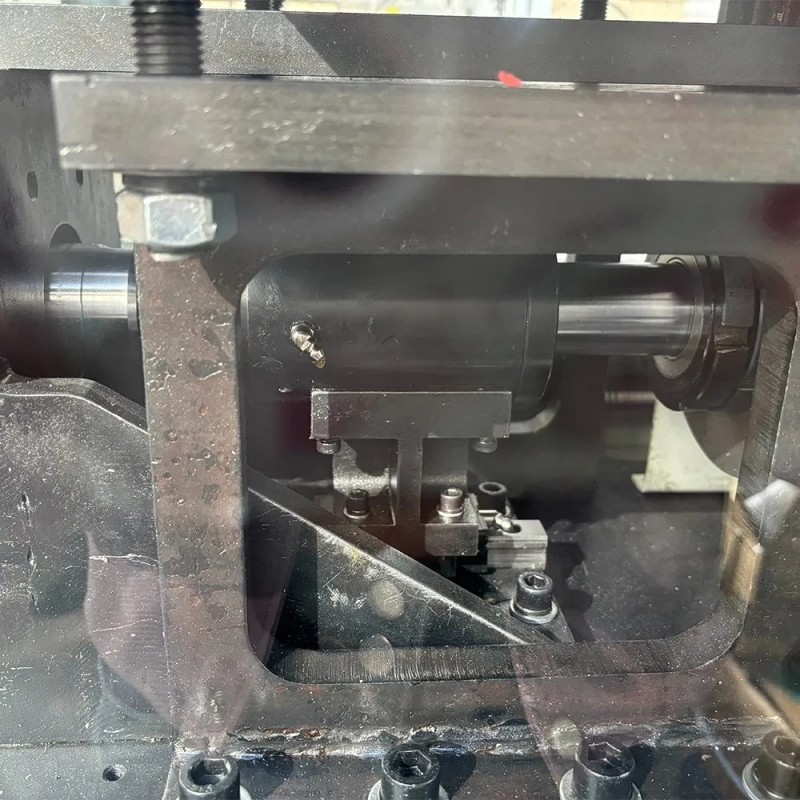

- The cutting tool feeds radially or axially along the pipe to perform the groove cutting.

- During cutting, either the pipe rotates (rotary grooving) or the tool rotates (tool-driven grooving) to form the desired groove.

- The clamping and positioning systems ensure high accuracy for the groove position and dimensions.

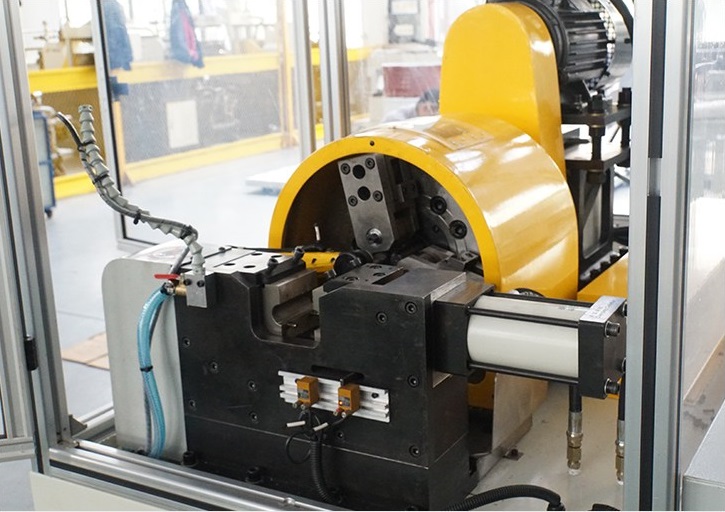

The machine is fitted with an independent positioning system; the clamping cylinder drives the fixture to hold the workpiece, the main cylinder pushes the upsetting die forward and backward, and the servo motor enables continuous station switching to sequentially complete the pipe-end grooving process.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.