ALEKVS Stamping Press Line Solutions

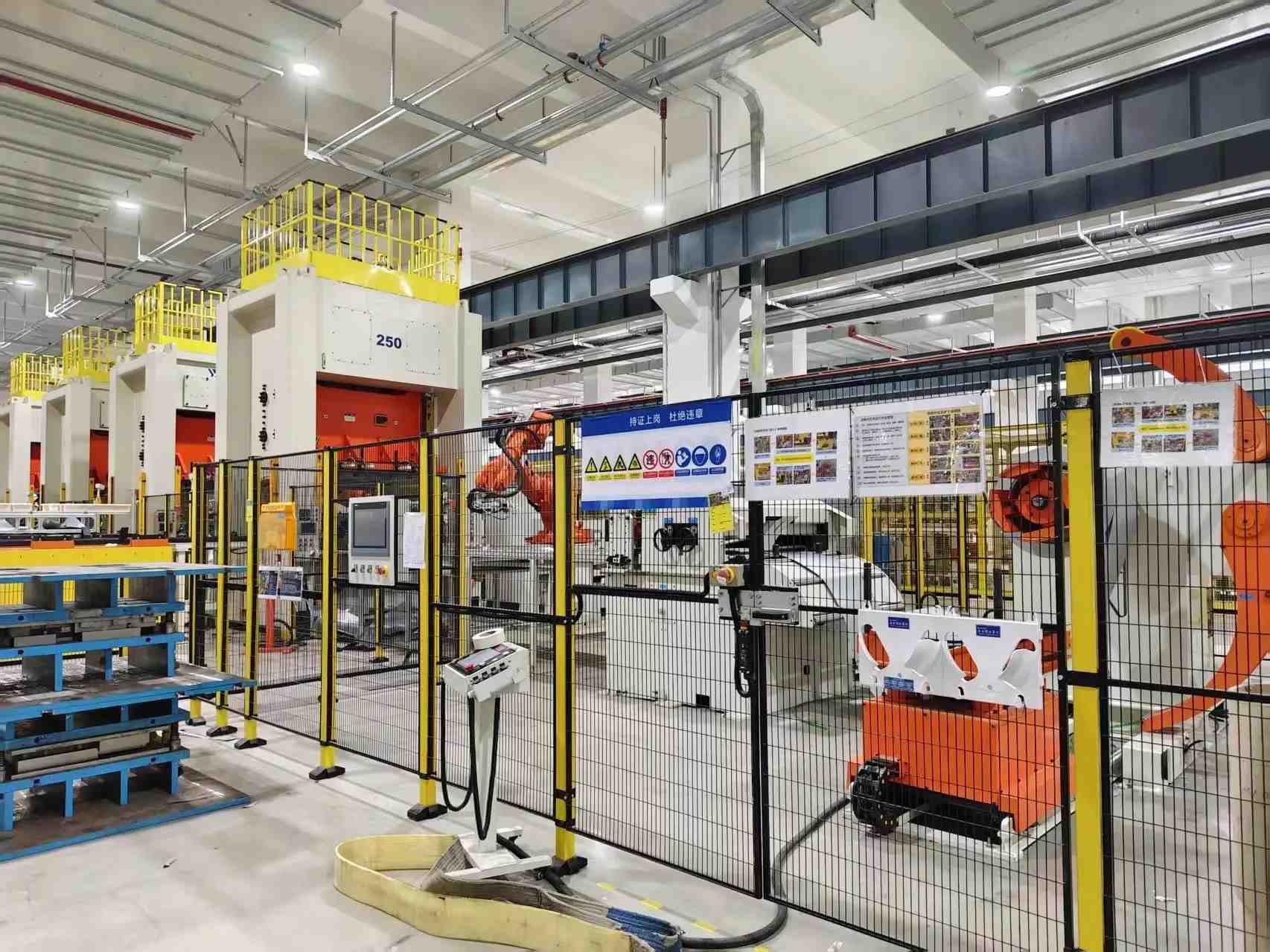

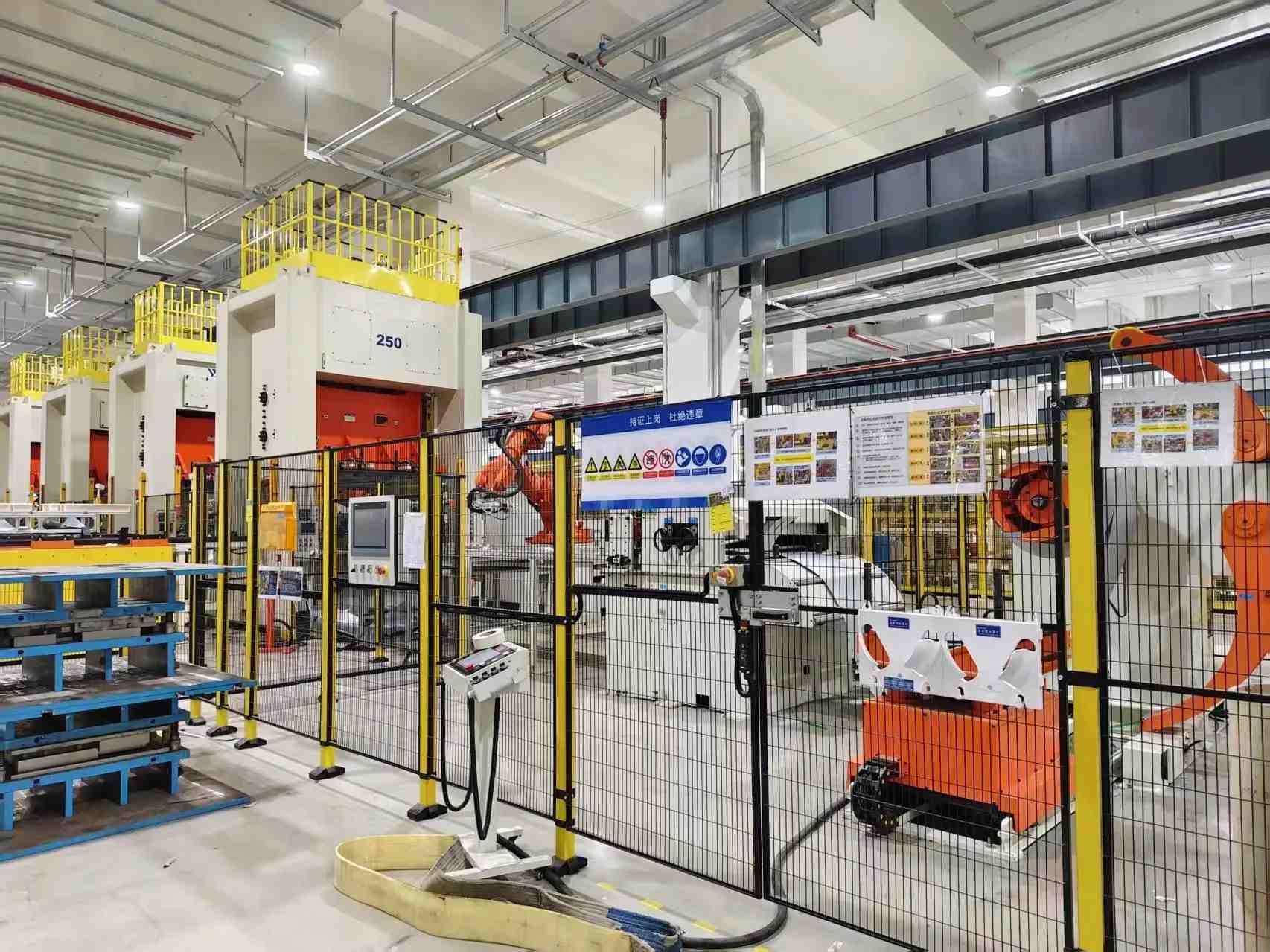

Front-of-Line Systems – Coil Feeding & Destacking

ALEKVS designs advanced Coil Feeding Lines and Front-of-Line Destacker Systems to handle steel and aluminum with speed, precision, and reliability.

Key capabilities include:

- Automatic blank pallet changers

- Destacking & blank separator stations

- Blank reject & centering stations

- Robotic vision blank picking

- Double blank detection

- Automatic robot tool changers

- Manual and automatic fanners

- Vacuum conveyors & universal destacking tools

- Continuous operation, high-speed up to 20 spm

- Steel and aluminum compatibility

These systems ensure consistent material flow for Automatic Stamping Lines and Metal Forming Lines, maximizing uptime from the very start of production.

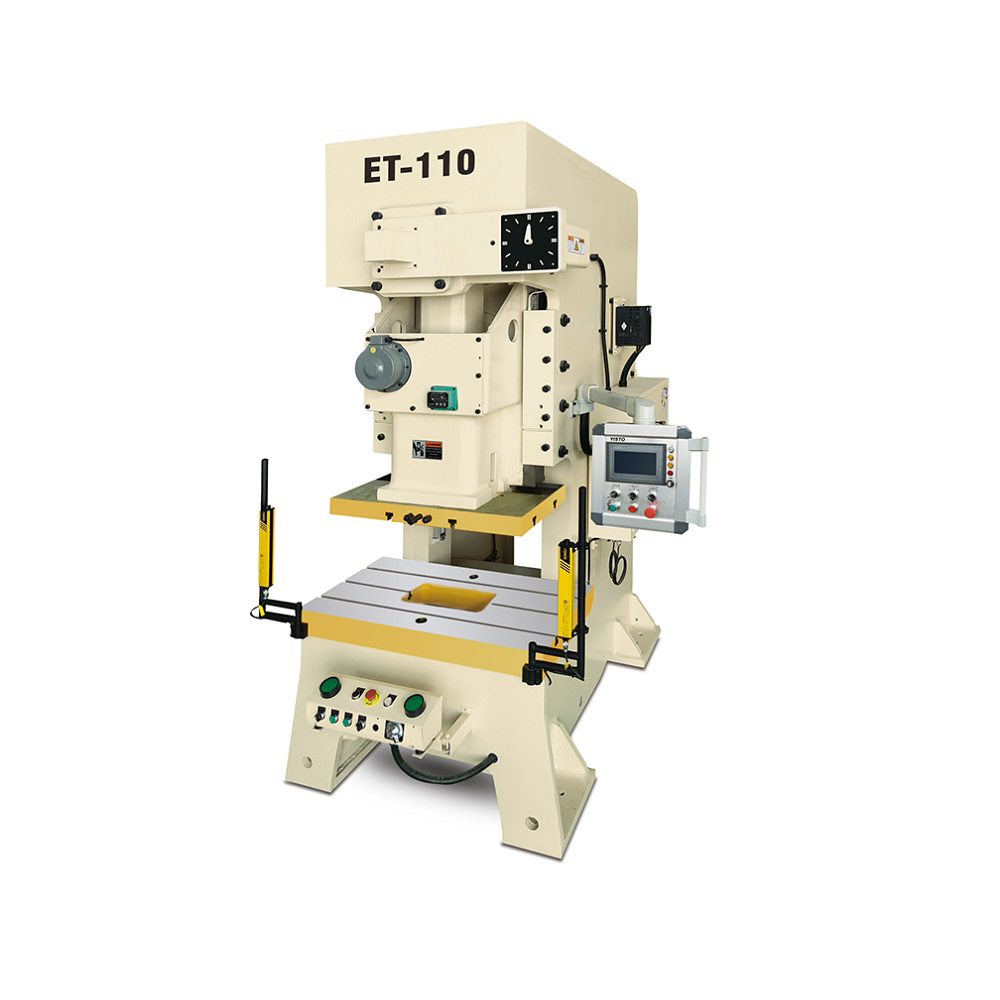

Press Automation – Stamping & Forming

ALEKVS offers a full range of press automation solutions for different manufacturing needs:

- Tandem Transfer Press Line: Multiple presses linked by robotic transfer for faster throughput and higher accuracy.

- Progressive Die Stamping Line: Continuous die operations for high-volume, high-precision production.

- Servo Feeder Press Line: Enhanced feeding precision, ideal for complex stamping geometries.

- Power Press Line: Heavy-duty presses for large-scale metal forming applications.

Each Stamping Press Line is engineered with flexible changeover capabilities and robust automation, ensuring consistent quality and reduced downtime.

End-of-Line Racking & Handling

ALEKVS provides safe, ergonomic, and adaptable End-of-Line Racking Systems designed for a wide range of stamped parts.

Available solutions include:

- Adjustable conveyors for different product sizes

- Shuttle pack-out systems for efficient sorting

- Exit conveyors for smooth part flow

- Fully automatic racking systems for reduced manual handling

These systems integrate seamlessly with Automatic Stamping Lines and Metal Forming Lines, helping manufacturers improve efficiency while ensuring operator safety.

Controls & Safety Upgrades

The lifespan of a press often exceeds its original control and safety systems. ALEKVS offers:

- Stamping Controls Upgrades: Reduce setup times, accelerate changeovers, and improve overall reliability.

- Safety System Modernization: Meet the latest OSHA and industry safety standards, with solutions tailored for presses from the 1960s to the latest models.

- Component Replacement: Swap out obsolete components to ensure continued production without costly downtime.

Our engineering team works across Coil Feeding Lines, Tandem Press Lines, Progressive Die Lines, and Servo Feeder Press Lines to ensure both peak performance and operator safety.