آلة الغزل الساخن CNC - نظرة عامة على التطبيق والعملية

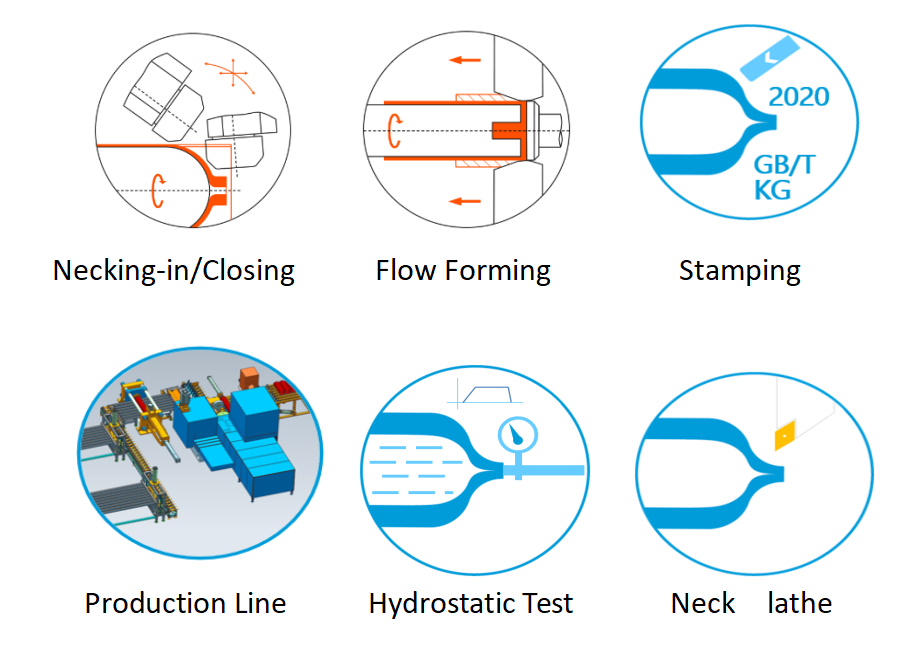

آلة الغزل الساخن CNC هي حل تشكيل عالي الكفاءة، مُصمم لإنتاج مكونات أسطوانية سلسة ذات جودة سطح عالية وسلامة هيكلية عالية. تُستخدم على نطاق واسع في تصنيع:

- أسطوانات الغاز عالية الضغط (CNG، LNG)

- أجسام الأسطوانات الهيدروليكية

- قيعان أوعية الضغط (أقسام التنورة)

- قذائف الذخيرة

- أنابيب رقيقة الجدران بدون لحامات مع تشطيبات ناعمة داخلية وخارجية

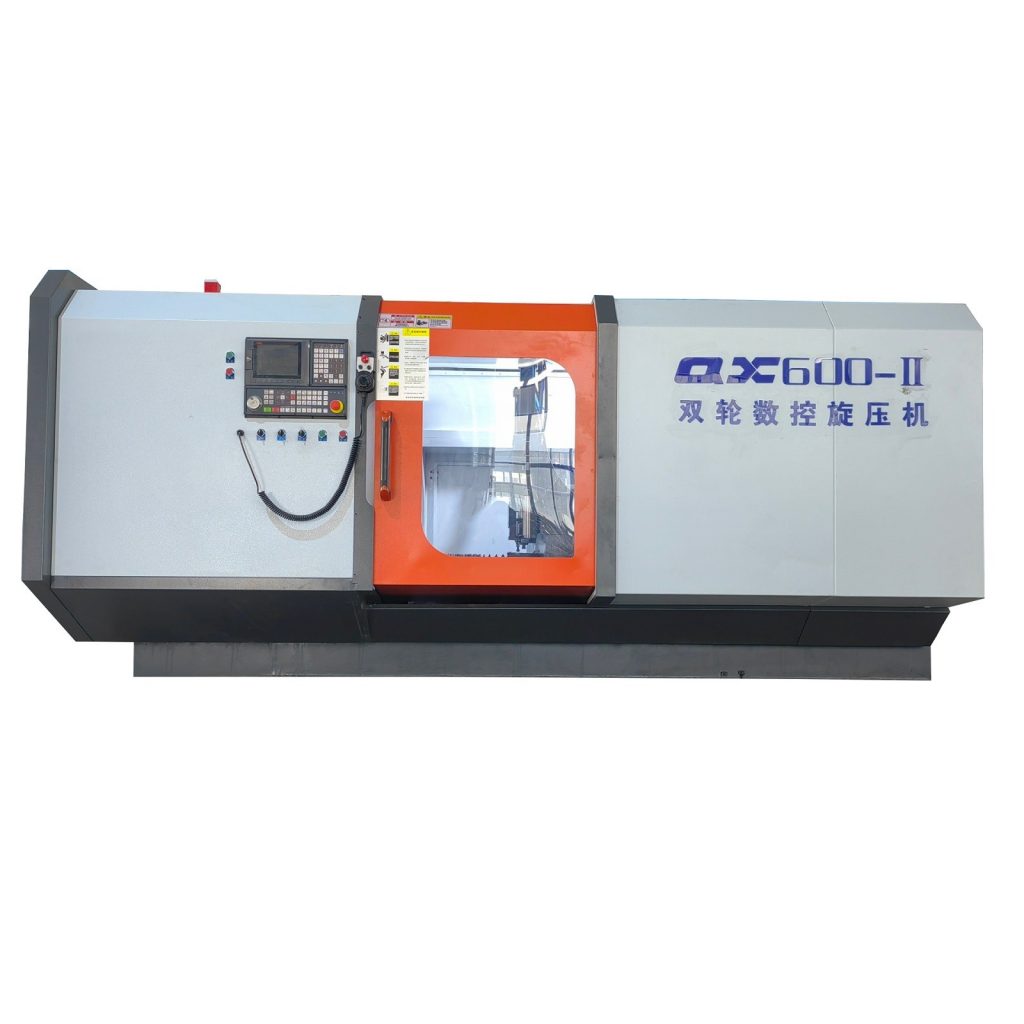

الوصف - آلة الغزل الساخن CNC لأسطوانات الغاز الطبيعي المضغوط

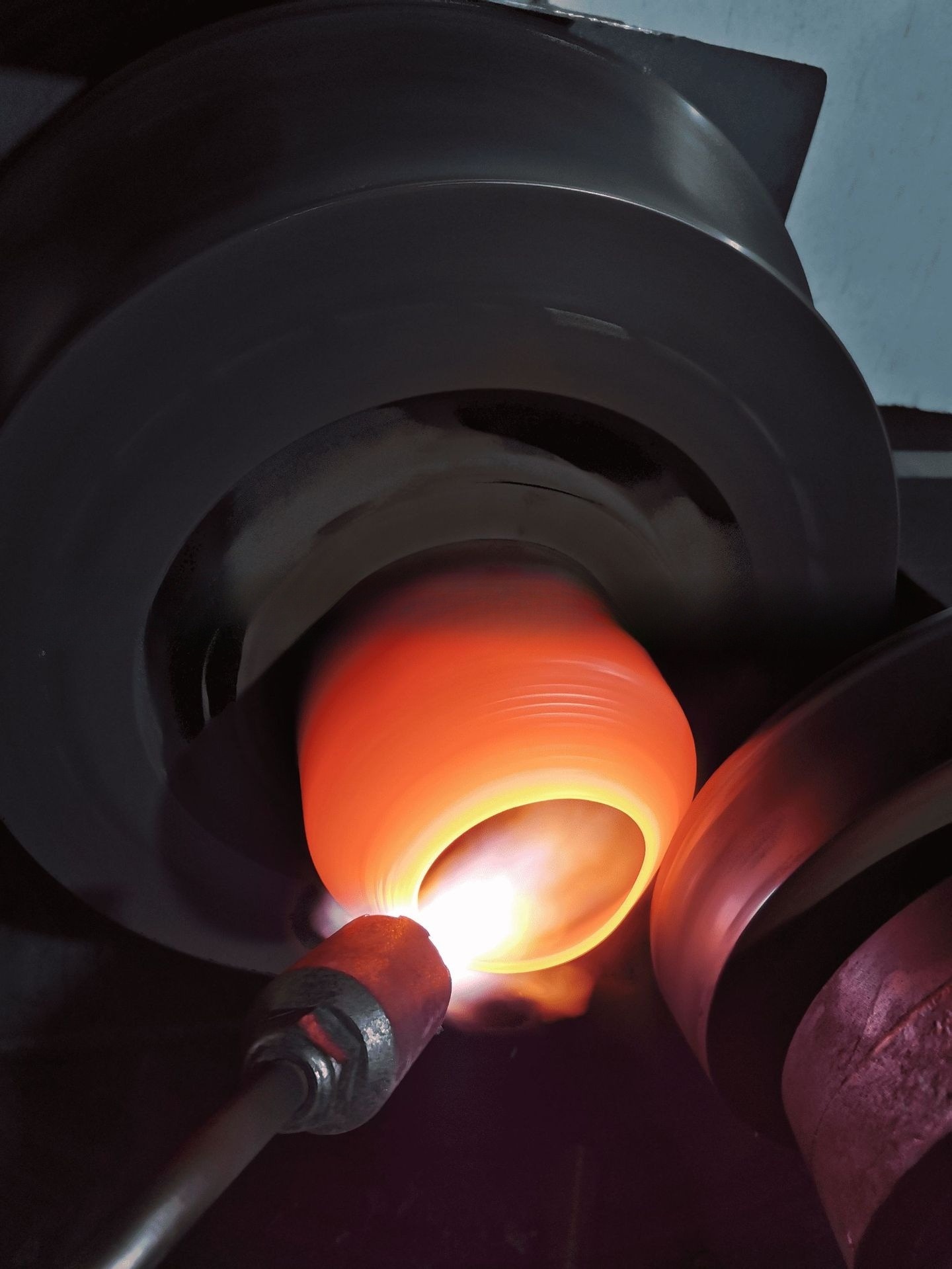

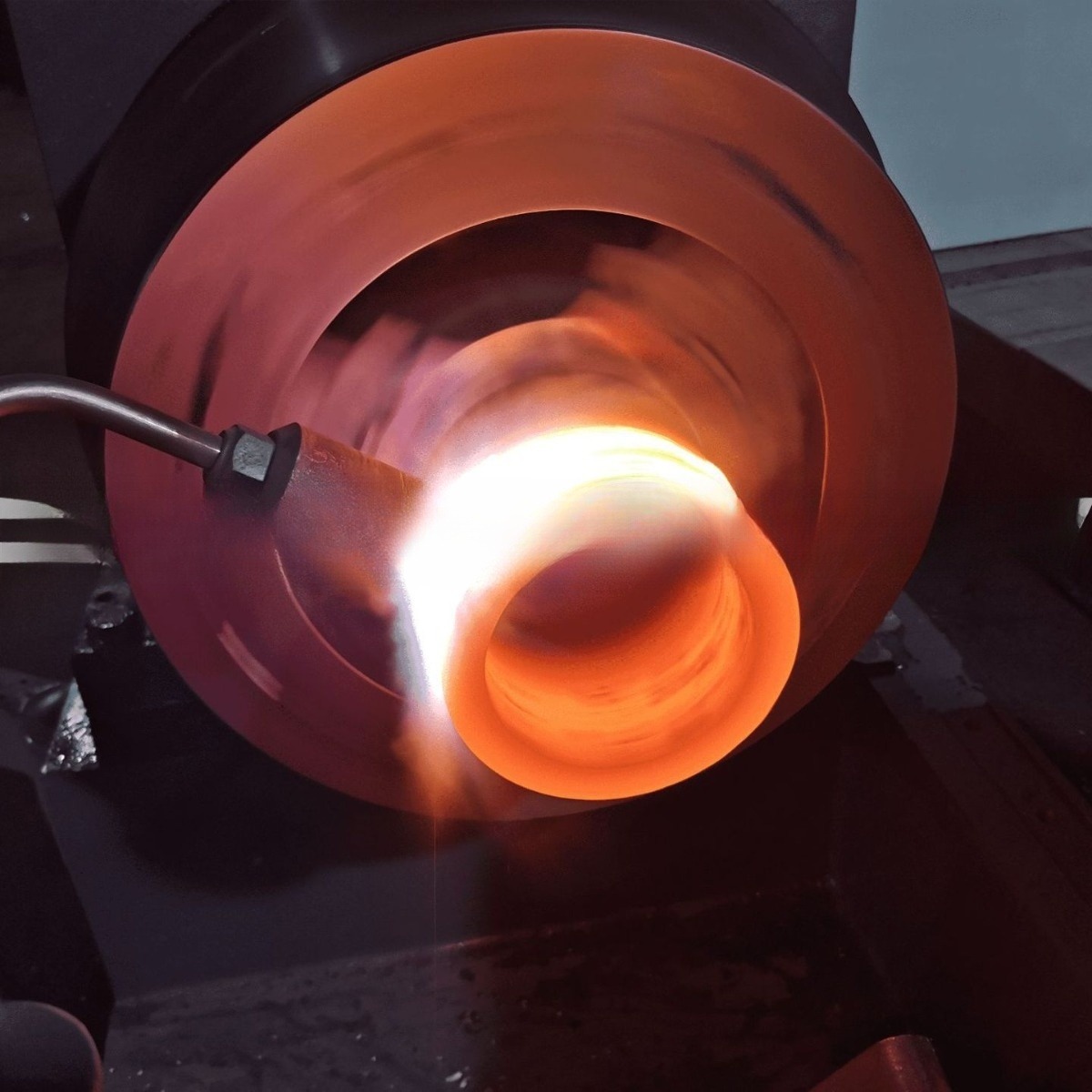

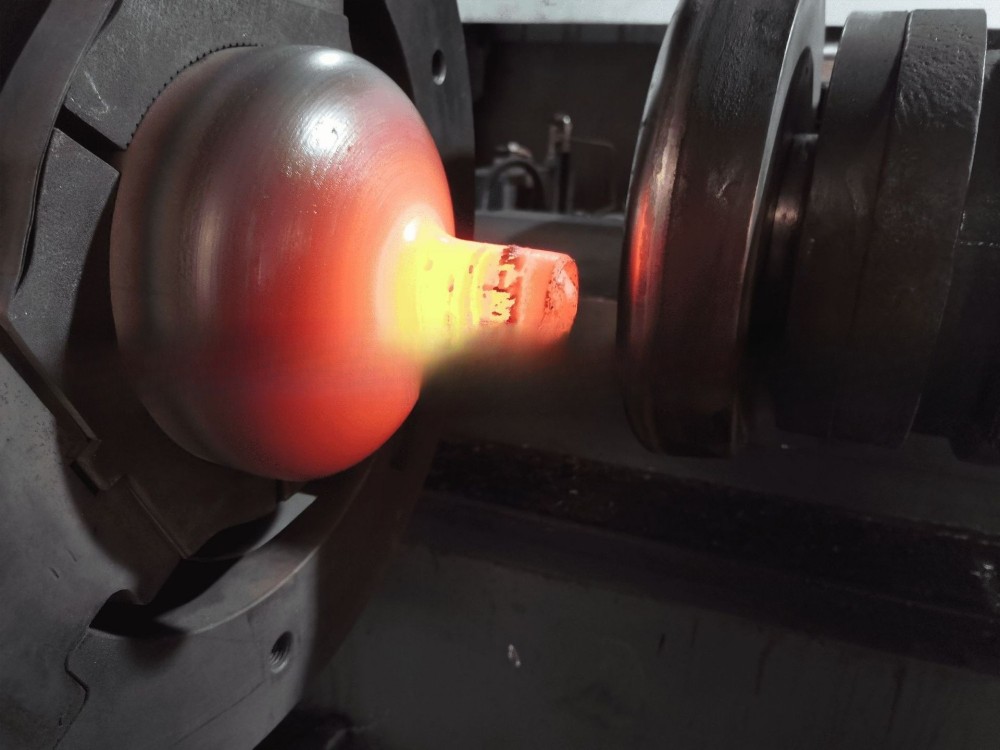

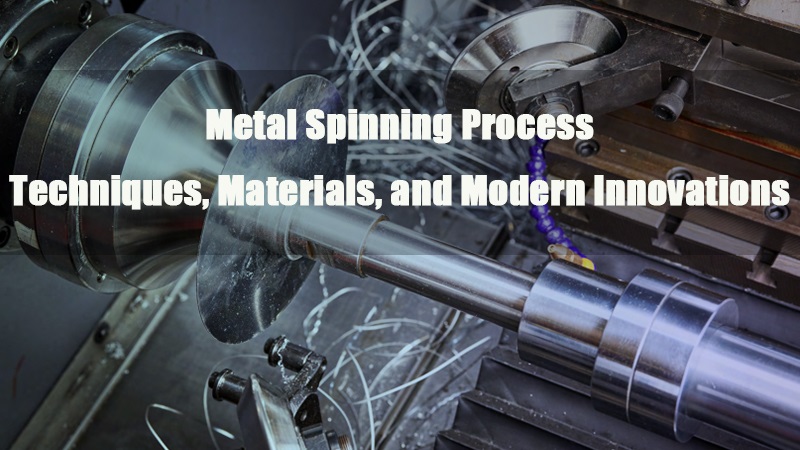

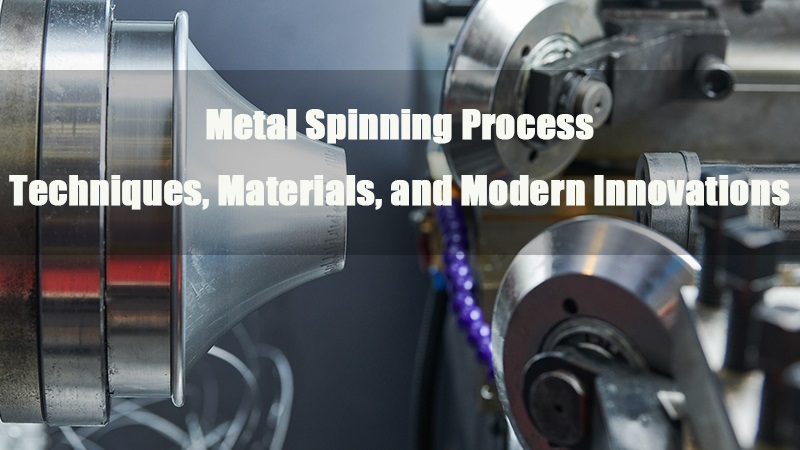

الغزل الساخن طريقة تشكيل متقدمة بدون رقائق، تُستخدم على نطاق واسع في إنتاج أسطوانات الغاز عالية الضغط. تُحسّن هذه العملية جودة السطح وتضمن انحناءً سلسًا ومستمرًا، مما يجعلها مثالية للمكونات الأسطوانية غير الملحومة.

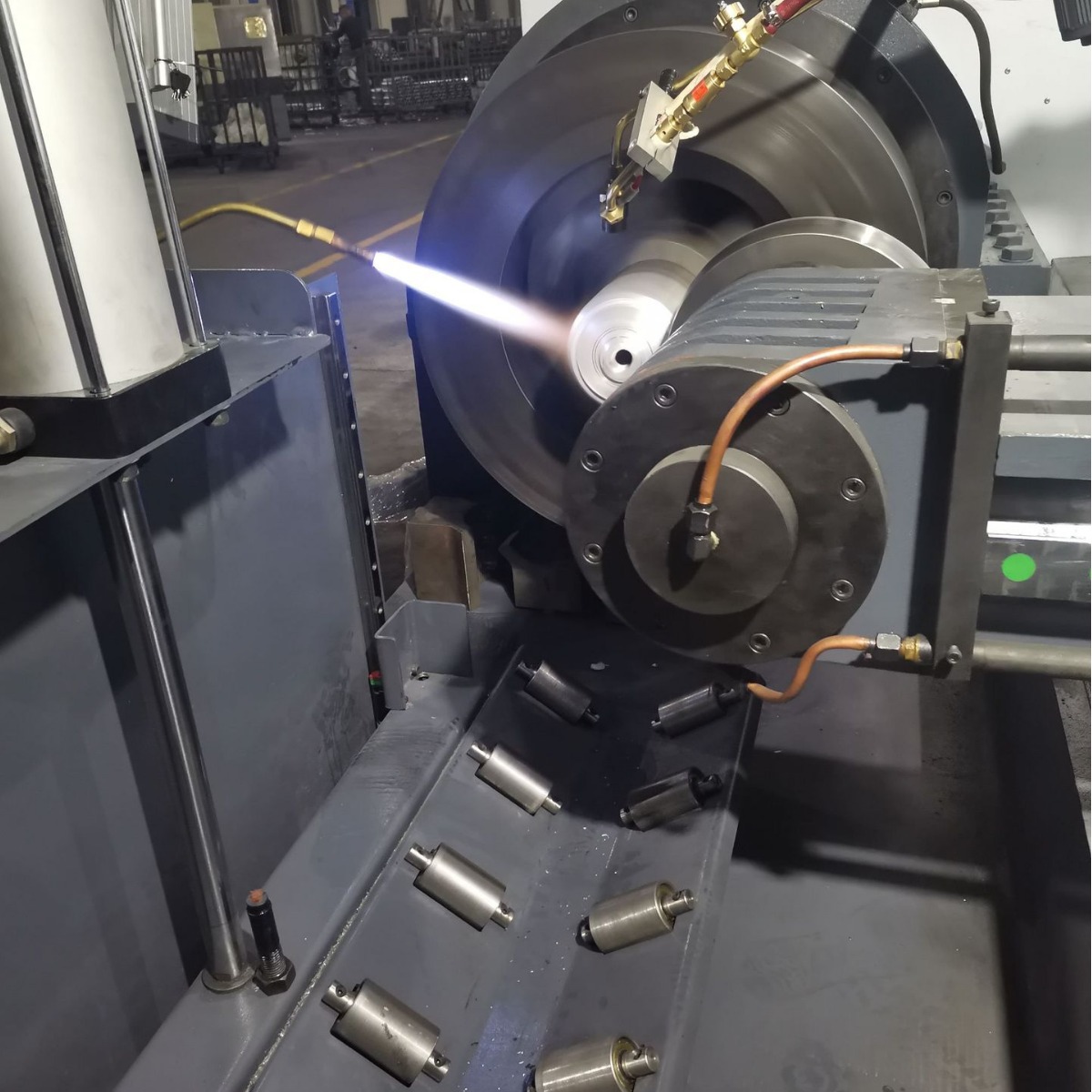

صُممت ماكينة الغزل الساخن CNC بدقة متناهية. يُركّب ذراع الغزل على سكة منزلقة موازية للمغزل الرئيسي، مما يضمن حركة دوران مثالية وأداء تشكيل فائق. صُممت كل تفصيلة هيكلية بعناية فائقة لتحقيق تشكيل دقيق ونتائج متسقة.

بناء خط آلة الغزل الساخن لأسطوانة CNG:

- نظام التدفئة متوسط التردد

- خط الإرسال

- نظام التحميل والتفريغ

- آلة الغزل الساخن

- نظام المكملات الحرارية

- النظام الهيدروليكي

- نظام التحكم الكهربائي

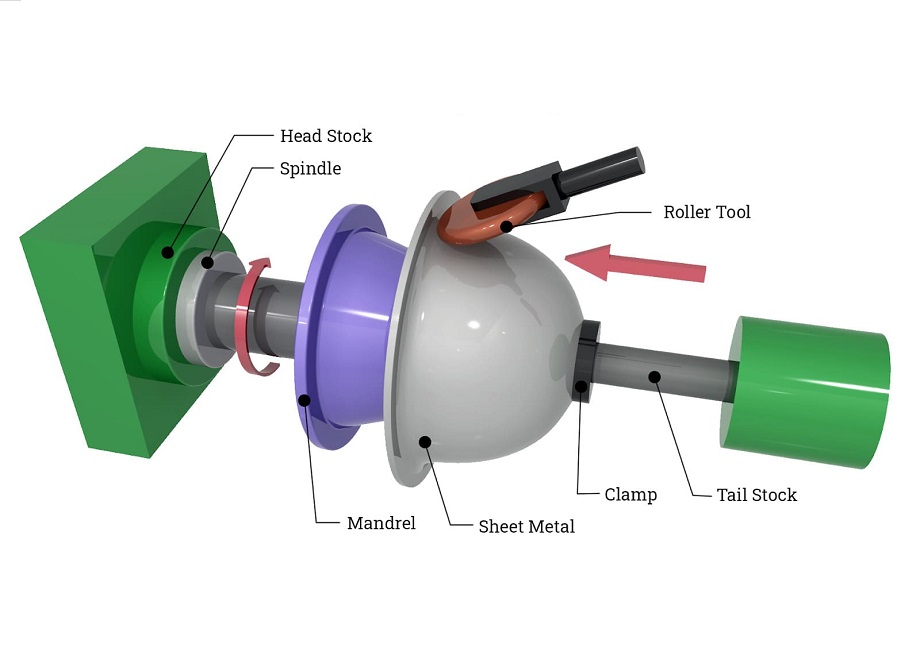

مبادئ عملية الغزل

عملية الغزل باستخدام الحاسب الآلي (CNC) هي طريقة تشكيل معادن بدون شظايا. تدور قطعة دائرية فارغة أو أنبوبية بسرعة عالية أثناء ضغطها بواسطة بكرة تشكيل. هذا يُمكّن المادة من التدفق بسلاسة، بما يتوافق مع الشكل المطلوب.

يرجى ملء هذا النموذج لتقديم طلب عرض أسعار. سيراجع أحد أعضاء فريقنا التفاصيل وسيتواصل معك خلال 12 ساعة عمل.