- 1.0Why Is Aluminum Extrusion the Preferred Process in Industrial Manufacturing?

- 2.0What Are the Core Material Advantages of Aluminum Alloys for Extrusion?

- 3.0What Unique Competitive Advantages Does the Extrusion Process Provide?

- 4.0What Are the Principles and Core Steps of the Aluminum Extrusion Process?

- 4.1What Is the Basic Principle of Aluminum Extrusion?

- 4.2What Are the Key Production Steps from Billet to Finished Extrusion?

- 4.3How to Control the Core Technical Parameters of Aluminum Extrusion?

- 4.4How Does the Extrusion Ratio Balance Product Strength and Processing Difficulty?

- 4.5How Do Shape Factor and Circumscribed Circle Diameter Affect Process Design?

- 4.6Shape Factor Classification & Process Requirements

- 4.7Circumscribed Circle Diameter & Press Selection

- 4.8What Are the Key Control Points for Temperature and Extrusion Speed?

- 4.9How to Select Aluminum Alloy Grades and Heat Treatment Processes?

- 5.0What Is the Selection Guide for Common Aluminum Alloy Grades?

- 6.0What Are the Application Scenarios for Different Heat Treatment Conditions?

- 7.0How Can Common Aluminum Extrusion Defects Be Prevented?

- 8.0What Are the Common Types of Aluminum Extrusion Defects?

- 9.0What Are the Causes and Preventive Measures for These Defects?

- 10.0What Are the Core Application Scenarios for Aluminum Extrusion Products?

- 11.0Frequently Asked Questions (FAQ)

1.0Why Is Aluminum Extrusion the Preferred Process in Industrial Manufacturing?

Aluminum extrusion has become a go-to manufacturing solution due to the combined advantages of aluminum alloy properties and the extrusion process itself. Together, they deliver irreplaceable competitiveness across performance, cost efficiency, and sustainability.

2.0What Are the Core Material Advantages of Aluminum Alloys for Extrusion?

Aluminum alloys are inherently well-suited for extrusion. Compared with traditional metals such as steel and copper, they offer clear advantages across key performance metrics:

- Extreme lightweight: With a density of only 2.7 g/cm³—approximately one-third that of steel—aluminum extrusions can reduce component weight by 10%–20% under equivalent strength requirements, making them ideal for vehicle lightweighting and structural optimization in curtain wall systems.

- High strength and formability: Standard aluminum alloys deliver yield strengths of 100–150 MPa, which can exceed 240 MPa after heat treatment. This balance supports both lightweight precision components and heavy-duty structural applications such as scaffolding and bridge guardrails.

- Natural corrosion resistance: Aluminum rapidly forms a dense Al₂O₃ oxide layer in air, enabling uncoated products to withstand long-term outdoor use without rust. When combined with anodizing or powder coating, corrosion resistance is further enhanced for coastal and industrial environments.

- High sustainability and recyclability: Aluminum is 100% recyclable. Producing recycled aluminum consumes only about 5% of the energy required for primary aluminum, reducing carbon emissions by up to 95% and aligning with global decarbonization initiatives.

- Comprehensive functional performance: Thermal conductivity is approximately five times that of steel, making aluminum ideal for heat sinks. Its excellent electrical conductivity and low weight suit busbars and conductive supports, while non-magnetic and non-combustible properties meet requirements in medical and fire-safe building applications.

3.0What Unique Competitive Advantages Does the Extrusion Process Provide?

If aluminum alloy is the “premium base material,” extrusion is the “precision shaping tool.” By integrating heat and pressure into a single forming process, extrusion delivers advantages difficult to achieve with conventional methods:

- Exceptional design freedom: Complex cross-sections—including multi-slot profiles, hollow chambers, and irregular geometries—can be extruded in one step without secondary welding, eliminating weak joints and significantly improving efficiency and dimensional accuracy.

- High-dimensional consistency: Modern extrusion equipment controls standard profile tolerances within ±0.1 mm, with high-precision products reaching ±0.05 mm. Continuous forming ensures uniform dimensions and performance across batches, avoiding variability common in casting.

- Ease of machining and assembly: Aluminum is easy to cut, drill, and bend. Assembly features such as T-slots and screw channels can be integrated during extrusion, eliminating secondary drilling or welding and improving assembly efficiency by over 30%.

- Excellent surface treatment compatibility: Extrusions readily support anodizing, powder coating, and electrophoretic painting, delivering corrosion resistance, wear resistance, and aesthetic finishes tailored to different applications.

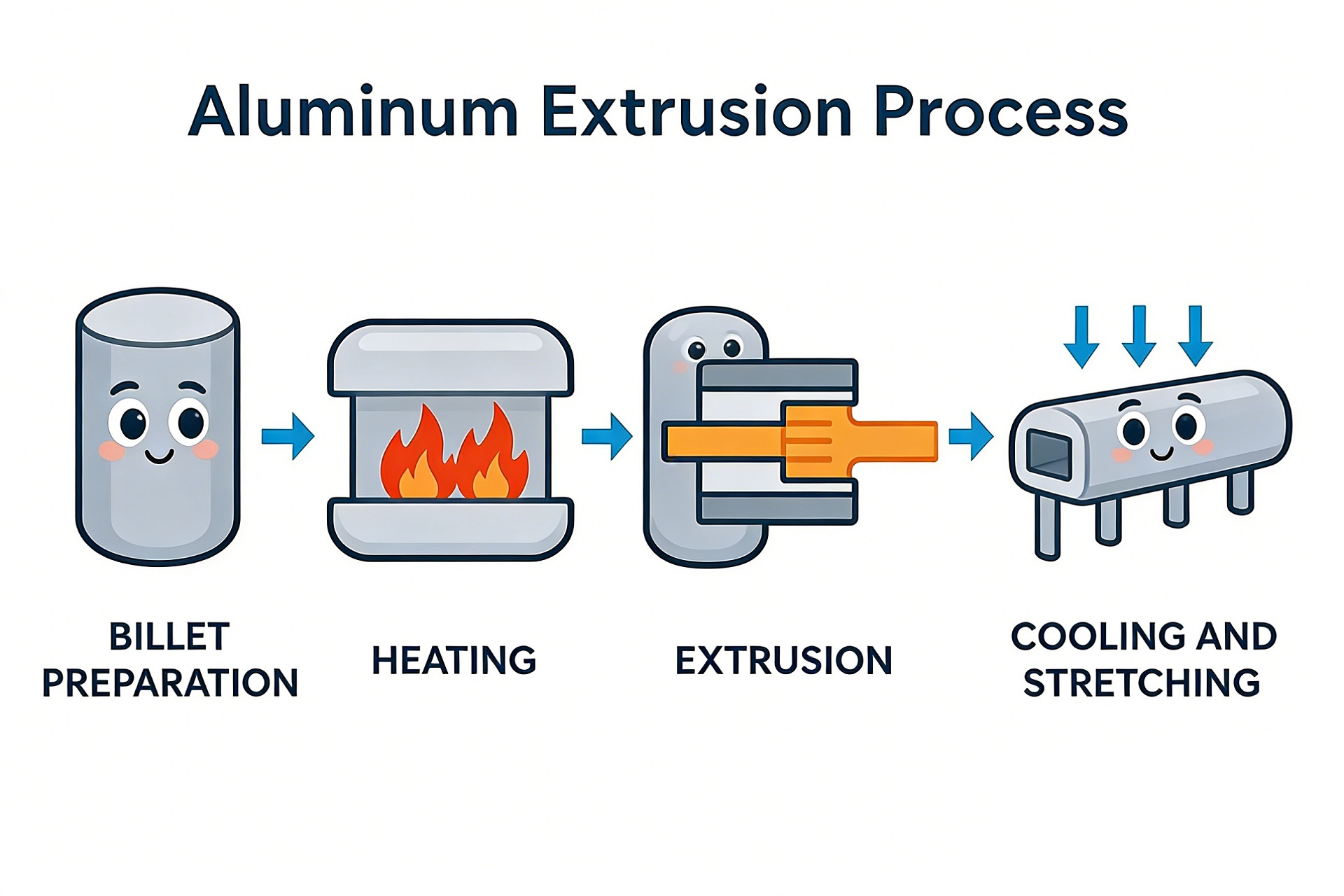

4.0What Are the Principles and Core Steps of the Aluminum Extrusion Process?

The aluminum extrusion process can be summarized as “thermal softening + die shaping + continuous forming.” From billet to finished product, multiple precision-controlled steps work together to ensure consistent quality.

4.1What Is the Basic Principle of Aluminum Extrusion?

Aluminum extrusion involves heating aluminum alloy billets to a thermoplastic state at approximately 450–500°C. Under high pressure (typically 100–300 MPa) generated by an extrusion press, the metal is forced through a custom-designed die to form profiles, tubes, or bars with a specific cross-section. The process resembles squeezing toothpaste: the billet acts as the material, and the die as the outlet—though precise control of temperature, pressure, and speed is critical to avoid defects. Based on structural requirements, extrusion is mainly classified into two types:

- Direct extrusion: Accounting for over 80% of market output, the billet is pushed directly toward the die by the ram. The process features a simple setup and high efficiency, suitable for solid bars, standard profiles, and simple tubes.

- Hollow extrusion: Metal is divided by a die bridge and rejoined in a welding chamber before exiting as a hollow profile. This more complex process enables integrated hollow sections used in curtain wall frameworks and automotive structural components.

4.2What Are the Key Production Steps from Billet to Finished Extrusion?

A complete aluminum extrusion line consists of seven essential stages, each governed by strict technical standards:

- Raw material preparation: Alloying elements are proportioned to meet performance requirements, melted, and cast into billets. Homogenization annealing eliminates segregation, while ultrasonic inspection removes billets with porosity or cracks to ensure material integrity.

- Die design and manufacturing: Based on cross-section drawings, dies are designed using CAD and optimized with simulation software to control metal flow. H13 tool steel is commonly used, with die tolerances controlled within ±0.03 mm. Nitriding or PVD coatings are applied to extend die life.

- Heating: Billets are heated to 450–500°C depending on alloy composition, while dies are preheated to 250–350°C to ensure smooth metal flow, proper plasticity, and reduced die wear or surface scratching.

- Extrusion forming: Heated billets are loaded into the container, and the ram applies pressure at speeds of 5–15 m/min to continuously extrude the profile through the die. Simple sections allow higher speeds, while complex geometries require reduced speeds and graphite-based lubrication to minimize friction.

- Cooling and straightening: Hot extrusions (300–400°C) are rapidly cooled using air or water to stabilize dimensions. Hydraulic straightening corrects bending or twisting to meet straightness and tolerance requirements.

- Cutting and secondary fabrication: Profiles are cut to customer-specified lengths (typically 3–6 m) using dedicated aluminum cutting saws with cooling systems to prevent oxidation or deformation. Frame and support components may undergo bending operations to achieve curves or angles, with precise control to prevent cracking or springback.

- Surface treatment and final inspection: Depending on application requirements, anodizing or powder coating is applied to enhance corrosion resistance and appearance. Dimensional checks are performed using calipers and CMMs, mechanical properties are sampled, and ultrasonic testing detects internal defects. Qualified products are film-wrapped for protection during transport.

4.3How to Control the Core Technical Parameters of Aluminum Extrusion?

Technical parameters directly determine product quality and production efficiency. Mastering the control logic of key parameters is essential to achieving high-quality aluminum extrusion.

4.4How Does the Extrusion Ratio Balance Product Strength and Processing Difficulty?

The extrusion ratio is the ratio of the billet cross-sectional area to the finished product cross-sectional area, calculated as:Extrusion ratio (K) = Billet area (A₀) / Finished profile area (A₁).

| Extrusion Ratio Range | Characteristics & Impacts |

| K < 20 | Insufficient metal deformation leads to coarse grains, low strength, and a higher risk of microstructural non-uniformity. |

| K > 80 | Extrusion pressure increases sharply, accelerating die wear and increasing the likelihood of surface scratches and cracking. |

| 30–60 (Optimal for 6063/6061) | Provides sufficient deformation, excellent mechanical properties, and a balanced trade-off between productivity and die life. |

4.5How Do Shape Factor and Circumscribed Circle Diameter Affect Process Design?

4.6Shape Factor Classification & Process Requirements

Shape factor: Defined as the ratio of cross-sectional perimeter to area, it indicates profile complexity. Higher values correspond to more difficult metal flow.

| Shape Factor Range | Profile Type | Process Requirements |

| < 100 | Simple sections (round, rectangular) | Low extrusion difficulty, suitable for higher speeds and higher extrusion ratios. |

| > 200 | Complex sections (multi-slot, thin-wall, irregular) | Requires reduced extrusion speed and optimized die flow balancing to prevent twisting and uneven wall thickness. |

4.7Circumscribed Circle Diameter & Press Selection

Circumscribed circle diameter: The minimum circle enclosing the profile cross-section, which determines die size and press selection.

| Extrusion Press Type | Container Diameter | Suitable Profiles |

| Small | ≤150 mm | Small components with diameters under 150 mm. |

| Medium | 150–250 mm | Window and door profiles, automotive trim. |

| Large | >250 mm | Curtain wall mullions, bridge structural components. |

4.8What Are the Key Control Points for Temperature and Extrusion Speed?

Temperature and speed must be precisely matched to the alloy type. Typical reference parameters are as follows:

| Alloy Grade | Billet Temperature | Container Temperature | Die Temperature | Recommended Speed | Applicable Products |

| 6063 | 480–500°C | 500–520°C | 300–350°C | 5–10 m/min | Medium-complexity sections |

| 6061 | 460–480°C | 480–500°C | 280–320°C | 3–8 m/min | High-strength structural components |

| 7005 | 450–470°C | 470–490°C | 250–300°C | 3–5 m/min | Ultra-high-strength structures |

Control principles: Excessive temperature causes grain coarsening and reduced performance, while insufficient temperature increases extrusion resistance. Speed fluctuations should be controlled within ±5% to ensure stable metal flow.

4.9How to Select Aluminum Alloy Grades and Heat Treatment Processes?

Different alloy grades and heat treatment conditions are suited to specific applications. Accurate selection is critical to meeting performance requirements.

5.0What Is the Selection Guide for Common Aluminum Alloy Grades?

5.16000 Series Aluminum Alloys (Most Widely Used)

| Alloy Grade | Key Characteristics | Suitable Applications |

| 6060 | Excellent extrudability, smooth surface finish, moderate strength | Decorative trims, furniture frames |

| 6063 | Good corrosion resistance, yield strength 140–200 MPa after heat treatment | Doors, windows, curtain wall frames |

| 6061 | High strength, yield strength exceeding 240 MPa | Scaffolding, automotive structural components |

| 6082 | Slightly higher strength than 6061 | Heavy machinery, marine components |

5.27000 Series Aluminum Alloys (Ultra-High Strength)

| Alloy Grade | Key Characteristics | Suitable Applications |

| 7005 | Yield strength up to 310 MPa, relatively good processability | Aerospace, high-speed rail structural parts |

| 7075 | Highest strength, yield strength exceeding 500 MPa, poor extrudability | High-end defense, medical equipment |

5.3Other Special Alloys

| Alloy Grade | Key Characteristics | Suitable Applications |

| 6101 | Excellent electrical conductivity | Busbars, conductive supports |

| 5052 | Outstanding seawater corrosion resistance | Coastal decorative components, marine hardware |

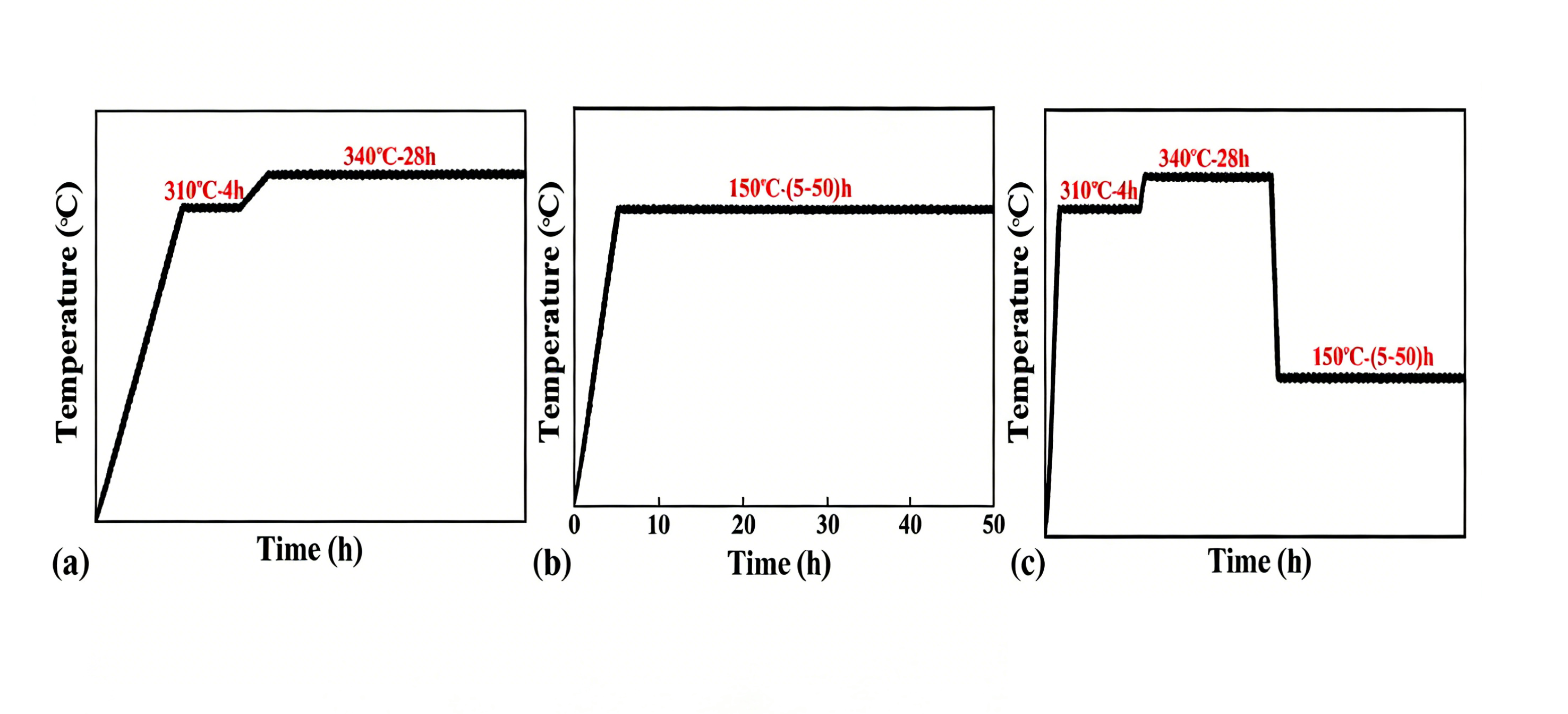

6.0What Are the Application Scenarios for Different Heat Treatment Conditions?

Heat treatment is a critical step for enhancing aluminum alloy strength. Common conditions and applications include:

| Heat Treatment Condition | Key Characteristics | Suitable Applications |

| T4 (Solution heat treatment + natural aging) | High ductility, elongation over 20% | Products requiring secondary bending or stamping |

| T5 (Direct artificial aging) | Simple process, low cost | Window systems, decorative profiles without secondary forming |

| T6 (Solution heat treatment + artificial aging) | Highest strengthening effect, maximum strength | Scaffolding, automotive structures, high-load applications |

| T73 (Over-aging) | Significantly improved corrosion resistance | Coastal, chemical, highly corrosive environments |

7.0How Can Common Aluminum Extrusion Defects Be Prevented?

Defects may arise from material quality, die condition, or process parameters. Following a “prevention-first, correction-second” approach can significantly reduce defect rates.

8.0What Are the Common Types of Aluminum Extrusion Defects?

Defects generally fall into three categories:

- Surface defects: Scratches, dents, blisters, peeling, and color variation, affecting appearance and corrosion resistance.

- Internal defects: Shrinkage cavities, porosity, delamination, and microstructural non-uniformity, reducing strength and sealing performance.

- Dimensional and shape defects: Twisting, bending, dimensional deviation, and uneven wall thickness, impacting downstream assembly.

9.0What Are the Causes and Preventive Measures for These Defects?

9.1Surface Defect Prevention

- Causes: Contaminated billet surfaces, die wear, excessive extrusion speed, insufficient lubrication.

- Measures: Strict billet surface inspection; regular die polishing and surface strengthening; controlled extrusion temperature and speed; uniform application of graphite-based lubricants.

9.2Internal Defect Prevention

- Causes: High hydrogen content in billets, improper die flow design, insufficient metal welding in hollow sections.

- Measures: Homogenization annealing to eliminate segregation; ultrasonic inspection to remove defective billets; optimization of die ports and welding chamber design.

9.3Secondary Processing Defect Prevention (Cutting and Bending)

- Causes: Worn saw blades or excessive cutting speed leading to burrs and edge chipping; improper bending pressure or poor die matching causing cracks or excessive springback.

- Measures: Regular replacement of cutting blades; adjustment of cutting speed and cooling based on wall thickness; selection of bending dies matched to profile geometry; trial bending to determine optimal pressure and angle. For high-strength alloys, preheating prior to bending can effectively reduce cracking risk.

10.0What Are the Core Application Scenarios for Aluminum Extrusion Products?

With advantages such as lightweight construction, high strength, and excellent machinability, aluminum extrusion products have penetrated multiple industrial sectors and become indispensable structural and functional components.

10.1What Are the Key Application Highlights in the Construction Sector?

Construction is the largest application market for aluminum extrusions, accounting for over 40% of total usage, primarily including:

- Doors, windows, and curtain walls: 6063-T5/T6 profiles are used for frames and mullions, offering lightweight performance and corrosion resistance while improving building energy efficiency and aesthetics.

- Structural and decorative components: Scaffolding, stair handrails, and sunshades combine structural strength with visual appeal and require minimal maintenance.

- Prefabricated buildings: Frames for precast façade panels and photovoltaic mounting systems enhance construction efficiency and align with green building concepts.

10.2What Lightweight Solutions Are Available in the Transportation Sector?

Weight reduction is a critical requirement in transportation, making aluminum extrusion a core lightweighting solution with an application share of approximately 25%:

- Automotive industry: Crash beams, chassis components, and thermal management systems reduce vehicle weight by 10%–20%, contributing to 5%–10% lower fuel consumption.

- Rail transit: Structural components for high-speed trains and metro vehicles improve operating speed and passenger comfort through lightweight design.

- Aerospace: Ultra-high-strength 7000-series profiles are used in fuselage and wing components to reduce takeoff weight and extend flight range.

10.3How Are Aluminum Extrusions Expanding in Industrial and Home Applications?

- Industrial applications(approximately 20% share): Machine tool guide rails, equipment enclosures, electronic heat sinks, and chemical pipeline supports tailored to diverse industrial requirements. Products such as automation equipment frames and conveyor supports typically require precision cutting with aluminum profile cutting machines and complex forming using aluminum profile bending machines to meet stringent assembly tolerances.

- Home and interior applications(approximately 10% share): Furniture frames, curtain tracks, and kitchen or bathroom storage systems offer moisture resistance, wear durability, and easy installation, enhancing overall living quality.

11.0Frequently Asked Questions (FAQ)

- Q: Which aluminum alloys are best suited for extrusion?A: 6000-series aluminum alloys (6063, 6061, 6082) offer the best extrudability. 7000-series alloys provide higher strength but are more difficult to extrude and are typically reserved for high-end structural applications.

- Q: What is the minimum achievable wall thickness for aluminum extrusions?A: Standard profiles generally require wall thicknesses ≥1.0–1.2 mm. Complex thin-wall or high-precision sections are usually controlled at ≥1.5 mm, depending on alloy selection, extrusion ratio, and die design.

- Q: How can a cross-section be identified as “high-difficulty extrusion”?A: High shape factors, multiple cavities, thin walls, asymmetrical geometries, or large circumscribed circle diameters significantly increase extrusion difficulty.

- Q: What dimensional tolerances can aluminum extrusion products typically achieve?A: Standard profiles can be controlled within ±0.1 mm, while high-precision profiles can reach ±0.05 mm with stable equipment and well-designed dies.

- Q: Is the welding strength of hollow profiles reliable?A: With properly designed die flow channels and welding chambers, weld strength can approach that of the base material and meet most structural application requirements.

- Q: Are aluminum extrusion products suitable for secondary processing?A: Yes. Aluminum alloys are easy to cut, drill, and bend. Assembly slots and features can be integrated during extrusion to reduce subsequent machining.

- Q: What are the most common quality defects in aluminum extrusion?A: Typical defects include surface scratches, blisters, internal porosity, uneven wall thickness, and twisting deformation, most of which are related to billet quality, die design, and process parameters.

Reference

www.gabrian.com/what-is-aluminum-extrusion-process/

bonnellaluminum.com/tech-info-resources/aluminum-extrusion-process/

us.misumi-ec.com/blog/types-of-aluminum-extrusion-profiles/

eagle-aluminum.com/what-is-extruded-aluminum/