- 1.0What is Aluminum Checker Plate?

- 2.0Applications of Aluminum Checker Plate: An Analysis of Uses

- 2.1Industrial Anti-Slip: The Core Scenario Prioritizing Safety

- 2.2Architectural Decoration: The “Aesthetic Leader” of Industrial Style

- 2.3Transportation and Marine: Dual Demands for Lightweight and Corrosion Resistance

- 2.4Furniture and Home: Combining Practicality and Aesthetics

- 2.5Equipment and Tools: A Choice for Protection and Durability

- 3.0Aluminum Checker Plate vs. Steel Checker Plate: How to Choose?

- 4.0Daily Maintenance: How to Clean Aluminum Checker Plate?

- 5.0The Complete Manufacturing Process of Aluminum Checker Plate

- 6.0Conclusion

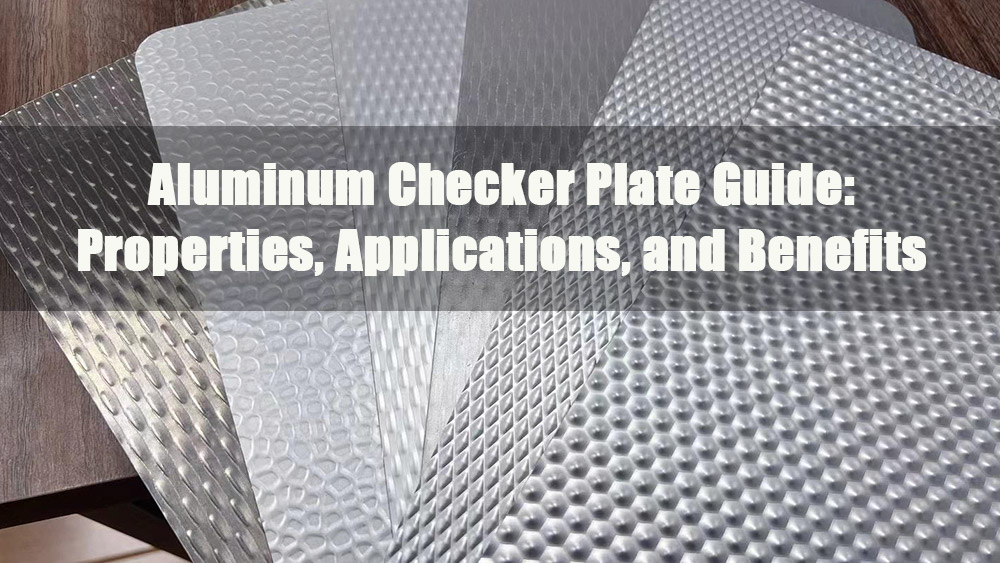

In the fields of industrial manufacturing and architectural decoration, there is a material that combines functionality and aesthetic value — aluminum checker plate (also known as aluminum tread plate). It features raised patterns (such as diamond, five-bar, lentil, etc.) formed on the surface of aluminum sheets through an embossing process.

1.0What is Aluminum Checker Plate?

Aluminum checker plate is a metal sheet that uses aluminum alloys (common grades include 6061, 5086, 3003, etc.) as the base material, with regular raised patterns formed on its surface through cold rolling or hot rolling embossing processes.

1.1Core Characteristics: 3 Major Advantages Determining Its Versatility

- Full-Featured Functionality: Raised patterns increase surface friction (the anti-slip coefficient is over 30% higher than that of flat aluminum sheets), and the patterned structure enhances the plate’s rigidity by 20%, making it more resistant to deformation than flat aluminum sheets of the same thickness.

- Outstanding Material Advantages: It is only 1/3 the weight of steel (facilitating transportation and installation), naturally corrosion-resistant (no frequent painting for maintenance), and easy to cut, drill, and weld.

- Balanced Aesthetics and Practicality: It comes with a variety of patterns (diamond, five-bar, lentil, etc.) and can achieve multi-color effects (silver, black, bronze, etc.) through anodization and spraying, combining industrial style with a modern look.

1.2Common Pattern Types: Choosing the Right Pattern = Using It in the Right Scenario

Different patterns vary significantly in anti-slip performance and aesthetics, so accurate matching to requirements is essential during selection:

| Pattern Type | Core Features | Suitable Scenarios |

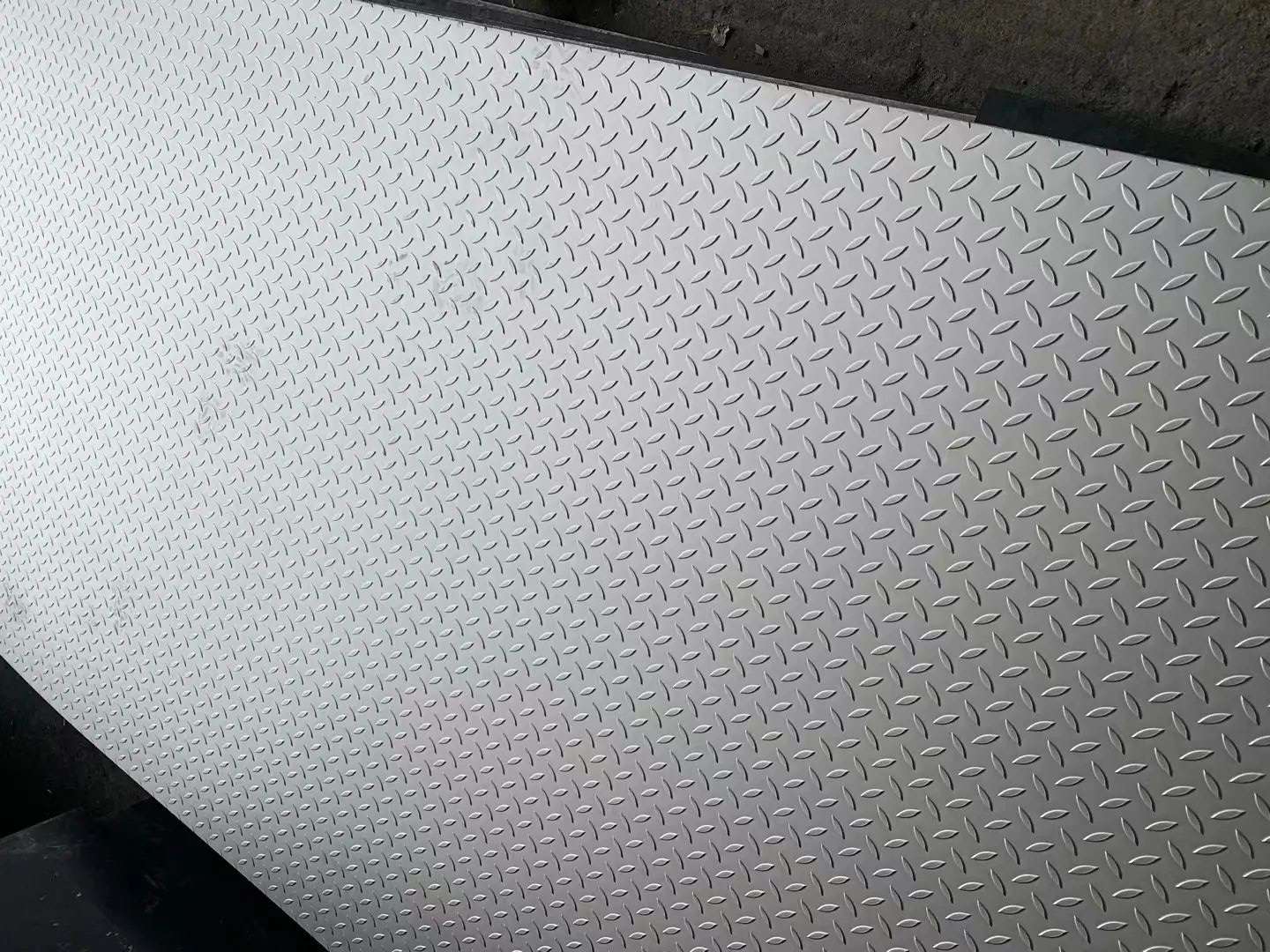

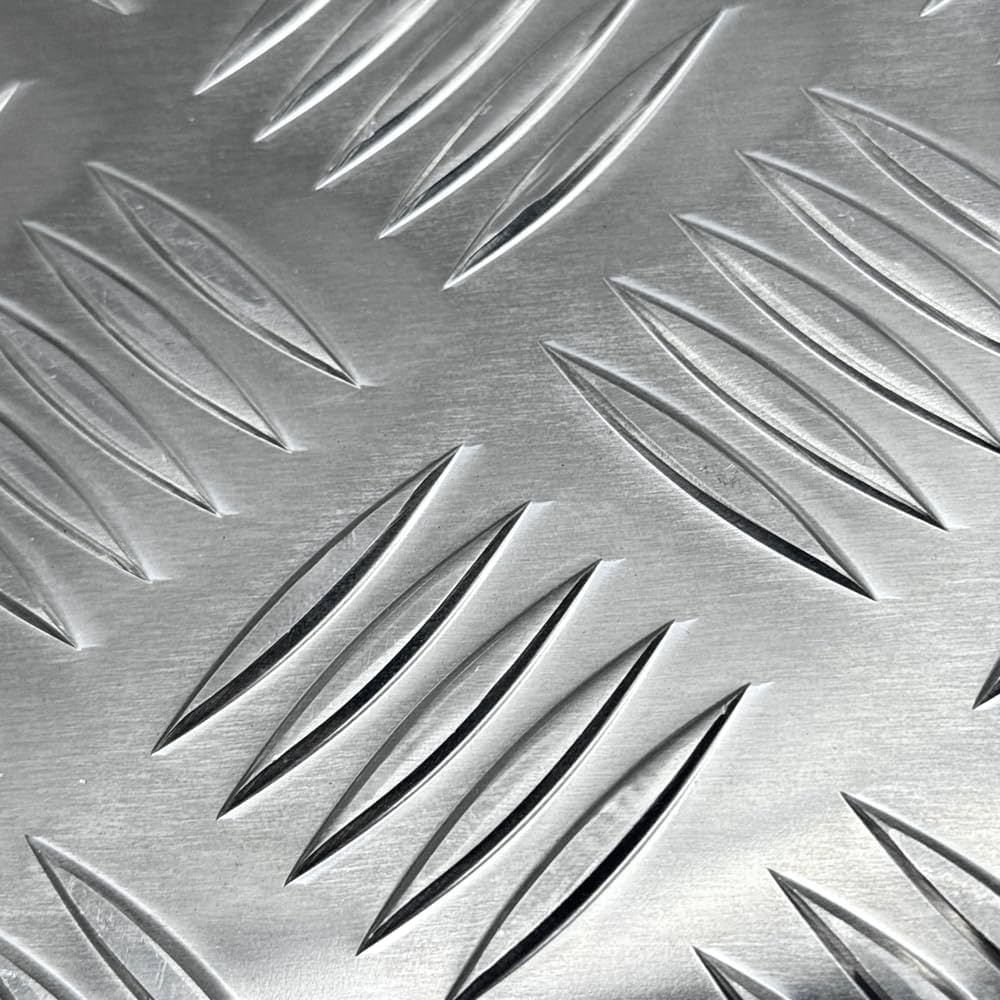

| Diamond | Strongest anti-slip performance, high three-dimensional effect | Industrial floors, truck beds, stair treads |

| Five-Bar | Good rigidity, easy to clean | Equipment platforms, solar brackets, furniture panels |

| Lentil | Delicate pattern, high aesthetic value | Interior decoration, kitchen countertops, and billboards |

| Willow | Soft touch, moderate anti-slip performance | Bathroom floors, children’s play areas, light-duty treads |

2.0Applications of Aluminum Checker Plate: An Analysis of Uses

The charm of aluminum checker plate lies in its “multi-purpose” nature — it can not only solve safety pain points in industrial scenarios but also meet the aesthetic needs of home decoration. Below are the 5 most mainstream application fields:

2.1Industrial Anti-Slip: The Core Scenario Prioritizing Safety

Anti-slip is the most core use of aluminum checker plate, especially suitable for humid, oily, and heavy-load environments:

- Factories and Warehouses: Workshop passages, equipment operation platforms (oil-resistant and easy to clean), loading and unloading docks (anti-slip and lightweight, reducing floor load-bearing).

- Public Facilities: Stair treads, overpass walkways (replacing steel plates to reduce building load), swimming pool/bathroom floors (water-resistant, anti-slip, and quick to drain).

- Transport Vehicles: Truck/refrigerated truck bed floors (preventing cargo displacement, lightweight to reduce fuel consumption), bus steps, RV floors (balancing anti-slip performance and weight reduction).

Case Study: Diamond-patterned aluminum checker plates are used on the floors of chemical workshops. They not only resist acid and alkali corrosion but also prevent slipping caused by accumulated water, with maintenance costs only 1/5 of that of steel anti-slip plates.

2.2Architectural Decoration: The “Aesthetic Leader” of Industrial Style

With the popularity of industrial-style design, aluminum checker plate has become a new favorite in architectural decoration:

- Exterior Walls and Storefronts: Storefront facades, office building exteriors (selecting rice-grain or small diamond patterns to enhance three-dimensionality, UV-resistant and non-fading).

- Interior Decoration: Bar/restaurant walls, ceilings (black anodization treatment to create a rough industrial feel), balcony railings (patterns hide scratches, weather-resistant and rust-proof).

- Functional Components: Elevator car floors (lightweight to reduce operating load), kick plates (impact-resistant and easy to clean).

2.3Transportation and Marine: Dual Demands for Lightweight and Corrosion Resistance

In the transportation and marine fields, “lightweight” and “corrosion resistance” are key requirements, and aluminum checker plate meets these perfectly:

- Vehicle Components: Truck running boards, SUV side steps (anti-slip and reducing vehicle weight), ambulance/fire truck floors (resistant to disinfectant corrosion and easy to clean).

- Ships and Yachts: Decks, steps (sea water corrosion-resistant, 60% lighter than steel, reducing ship draft).

2.4Furniture and Home: Combining Practicality and Aesthetics

In home scenarios, aluminum checker plate is mostly used for components requiring “durability + anti-slip performance”:

- Kitchen Areas: Countertops, oil-proof baffles (oil-resistant, patterns reduce water stain residue).

- Storage Furniture: Metal cabinet doors, wardrobe partitions (patterns increase friction to prevent items from slipping; aluminum material is moisture-proof, suitable for humid environments in southern regions).

- Industrial-Style Furniture: Desk tops, coffee tables (five-bar patterns balance anti-slip performance and texture).

2.5Equipment and Tools: A Choice for Protection and Durability

- Equipment Casings: Generator and water pump protective covers (patterns enhance impact resistance, lightweight for easy movement).

- Toolboxes and Instrument Cases: Maintenance toolboxes, outdoor testing instrument cases (scratch-resistant, patterns hide usage marks, moisture-proof to protect internal tools).

3.0Aluminum Checker Plate vs. Steel Checker Plate: How to Choose?

Many people struggle with the difference between aluminum checker plate and steel checker plate. In fact, the key lies in matching the scenario requirements:

| Comparison Dimension | Aluminum Checker Plate | Steel Checker Plate (Carbon Steel/Stainless Steel) |

| Weight | Light (1/3 the weight of steel), easy to install and transport | Heavy, suitable for fixed load-bearing scenarios |

| Corrosion Resistance | Naturally corrosion-resistant (especially grades 3003/5086) | Carbon steel is prone to rust; stainless steel has high cost |

| Workability | Easy to cut, bend, and weld | Difficult to process, requiring professional equipment |

| Cost | Medium (higher than carbon steel, lower than stainless steel) | Low for carbon steel; high for stainless steel |

| Suitable Scenarios | Lightweight requirements (RVs, elevators), humid environments (swimming pools, ships) | Heavy-load fixed scenarios (heavy-duty workshop floors), high-temperature environments |

4.0Daily Maintenance: How to Clean Aluminum Checker Plate?

Aluminum checker plate has extremely low maintenance costs. Only 2 points need to be noted for daily cleaning:

- Regular Cleaning: Wipe with mild soapy water (or neutral detergent), then rinse with clean water (suitable for home and commercial scenarios).

- Heavy Stains: In industrial scenarios (such as workshop oil stains), soak in diluted alkaline detergent for 5 minutes first, then gently scrub with a soft-bristle brush. Avoid using steel wool to scratch the surface.

- Precautions: Avoid long-term contact with strong acids (such as hydrochloric acid), as this will damage the aluminum oxide film and reduce corrosion resistance.

5.0The Complete Manufacturing Process of Aluminum Checker Plate

5.1Early Stage: Base Material Preparation

Raw Material Melting and Ingot Casting

- Mix raw aluminum ingots (purity ≥99.7%) with alloying elements (silicon, magnesium, etc., matching grades like 3003/6061) in proportion, melt at 700-750℃, then degas and remove slag to produce 50-80mm thick aluminum alloy cast rolls (aluminum ingots).

Cold Rolling and Pre-Treatment

- Subject the aluminum ingots to 3-5 passes of cold rolling to produce flat base materials with a thickness of 1-5mm (tolerance ≤0.05mm); then degrease with alkaline solution, clean with water, and dry to remove surface oil stains and ensure embossing adhesion.

- For thick base materials (≥3mm), preheat to 300-400℃ to improve plasticity for subsequent embossing.

5.2Core Stage: Forming with Metal Embossing Machine

Selecting the appropriate embossing process based on the thickness of the base material is a key step in differentiating aluminum checker plates:

Cold Rolling Embossing (for 1-3mm Thin Base Materials, Mainstream Process)

- Equipment Debugging: Use a multi-roll metal embossing machine, with the upper roll being a pattern die roll (made of Cr12MoV steel, hardness HRC58-62) and the lower roll being a smooth support roll; adjust the roll gap (matching the base material thickness), pressure (100-300MPa), and temperature (50-80℃).

- Continuous Embossing: The base material passes through the rolls, and the surface metal flows plastically to fill the die grooves, forming raised patterns such as diamond/five-bar (depth tolerance ≤0.1mm) at a conveying speed of 50-100 meters per minute. The pattern integrity is monitored online.

Hot Rolling Embossing (for 3-5mm Thick Base Materials, Used in Heavy-Load Scenarios)

- Preheat the Base Material: Heat the thick base material to 300-400℃ to ensure plasticity.

- High-Temperature Embossing: Use a high-temperature-resistant metal embossing machine (rolls can withstand temperatures above 500℃) to press deep patterns (1-2mm) under high pressure (300-500MPa), then cool and shape with air to enhance anti-slip performance.

Sheet metal embossing production site

5.3Later Stage: Treatment and Quality Inspection

Performance Enhancement

- High-Strength Alloys (e.g., 6061): Solution treatment (heating at 500-550℃ for heat preservation) + aging treatment (heating at 120-180℃ for heat preservation), increasing tensile strength by over 50%; ordinary alloys only require annealing to eliminate internal stress.

Surface Treatment

- Decorative Scenarios: Anodization (coating a 5-15μm oxide film, which can be dyed).

- Outdoor/Industrial Scenarios: Hot-dip galvanizing (coating a 5-10μm zinc layer for rust prevention) or fluorocarbon paint spraying (weather-resistant).

Finishing and Quality Inspection

- Use a leveler to correct the flatness of the plates (flatness tolerance ≤1mm/m), and cut them into standard/custom sizes with numerical control; inspect the patterns, appearance, tensile strength (≥150MPa), and corrosion resistance (salt spray test ≥48 hours). Qualified products are packaged and delivered.

6.0Conclusion

Aluminum checker plate may seem simple, but with its multi-dimensional advantages of “anti-slip + lightweight + corrosion resistance + aesthetics”, it has moved from industrial workshops to home life. Whether it is used for stair treads, truck beds, or decorative walls, the core principle is to “match patterns to scenarios” — prioritize diamond patterns for anti-slip needs, lentil patterns for decoration, and five-bar patterns for lightweight requirements.

References

https://www.sanghvioverseas.com/blog/what-are-aluminium-chequered-plates-and-their-applications/

https://www.smetals.co.uk/top-10-uses-for-aluminium-checker-plate/

https://aluminiumextrusions.com.au/products/aluminium-checker-plate

https://www.austrinasteels.com.au/blogs/articles/what-is-purpose-the-of-checker-plate