- 1.0What Is Aluminum Bending?

- 2.0Aluminum Bending Methods & Processes

- 3.0Best Methods for Bending Aluminum Angles

- 4.0How to Manually Bend Aluminum

- 5.0How to Use a Press Brake for Bending

- 6.0Best Materials for Aluminum Bending

- 7.0Key Factors Affecting Aluminum Bending

- 8.0How to Prevent Cracks During Aluminum Bending

1.0What Is Aluminum Bending?

Aluminum bending refers to the process of applying external force to transform a straight piece of aluminum into a curved or angled shape according to your design, all while retaining its structural integrity.

It’s important to note that not all aluminum materials are suitable for bending. The material’s properties and heat treatment can significantly affect the bending result. This is why we recommend that you consult with us in depth before proceeding, in order to identify the best solution for your project.

Bending can be a challenging process, requiring careful control to avoid issues such as cracking or deformation. In this article, we’ll walk you through these potential pitfalls and introduce eight of the most commonly used and reliable bending methods. If you’d like to achieve the highest quality bending solution for your products, please feel free to reach out to us at any time.

2.0Aluminum Bending Methods & Processes

The choice of aluminum bending technology directly depends on the material’s cross-section and specific requirements. Whether you’re working with aluminum sheets, tubes, or rods, there are various bending methods available. Choosing the most suitable bending technique is crucial to ensuring the success of your project.

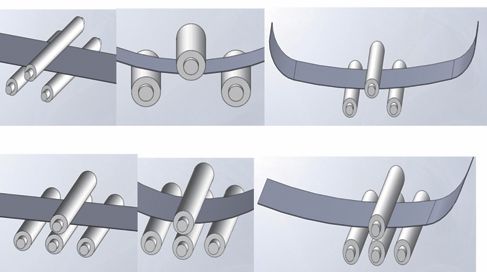

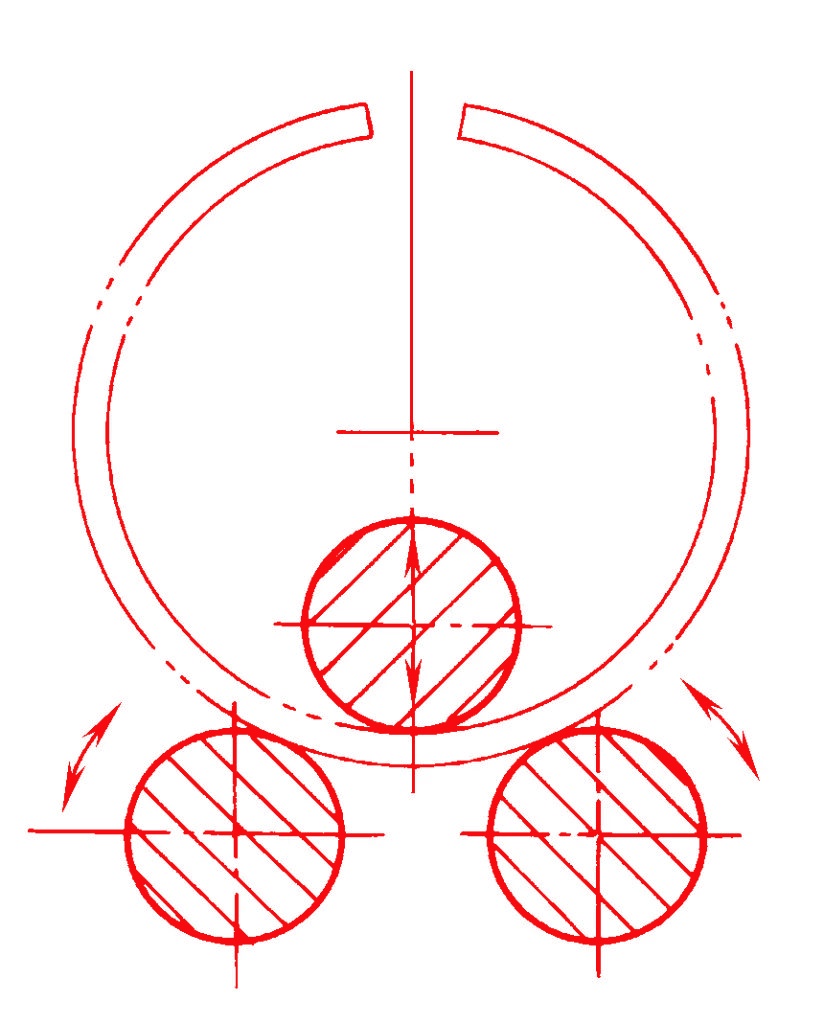

2.1Roll Bending

Roll bending involves placing the aluminum between two rollers and applying pressure through the rollers to bend the material to the desired angle and depth. This method is highly efficient for shaping aluminum into various forms and is ideal for large, thick pieces.

Advantages: Fast, consistent, and suitable for large aluminum sizes.

Disadvantages: Requires specialized equipment, which can be costly.

2.2Press Brake Bending

A press brake bends aluminum by placing it between a punch and die, where the punch applies pressure to force the aluminum to bend around the die.

Advantages: High precision, fast bending speed, suitable for large or thick aluminum pieces.

Disadvantages: Expensive equipment, best for smaller or thinner aluminum parts.

2.3Push Bending

Push bending uses a pushing tool or a rod to apply mechanical force to bend the aluminum. The material is clamped into a fixed device, and the pushing tool presses it into the desired shape.

Advantages: Ideal for small-angle bends.

Disadvantages: Not suitable for large or thick aluminum, may result in high localized pressure.

2.4Rotary Bending

Rotary bending uses a rotary stretching machine to apply mechanical force, causing the aluminum to rotate and bend between a central axis and die.

Advantages: Achieves small radii, precise angles, and smooth transitions, ideal for large or thick aluminum parts.

Disadvantages: Requires specialized equipment, which can be costly.

2.5Compression Bending

Compression bending applies pressure using a punch and die to compress the aluminum into the desired shape.

Advantages: Suitable for producing parts with consistent bends on both sides.

Disadvantages: High equipment costs, better for mass production.

2.6Stretch Forming

Stretch forming uses mechanical force to stretch aluminum and form it into the desired shape. The tension during the process ensures constant control over the material’s length.

Advantages: Precise shape control, ideal for high-volume production.

Disadvantages: Expensive equipment, suitable for specific needs.

2.7Manual Bending

Manual bending is the traditional method of bending aluminum using simple tools, such as pliers or hammers.

Advantages: Simple, low-cost, and ideal for small or thin aluminum parts.

Disadvantages: Slow, low precision, and not suitable for large or thick aluminum pieces.

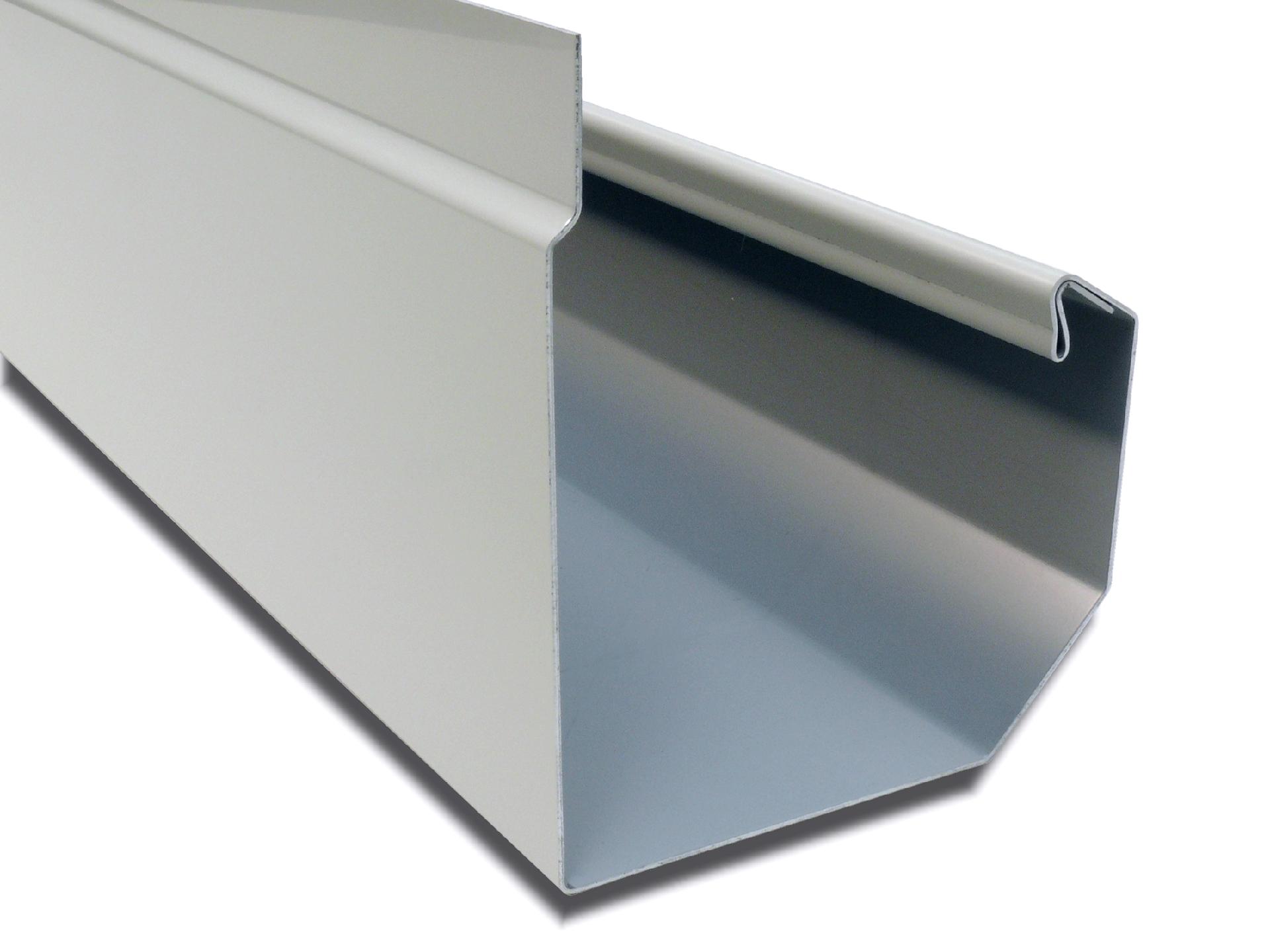

2.8Three-Roller Plate Bending Machine

The three-roller plate bending machine uses three rollers to apply pressure, bending the aluminum into the desired shape.

Advantages: Ideal for architectural components and large-scale construction projects.

Disadvantages: Expensive specialized equipment, limited application.

3.0Best Methods for Bending Aluminum Angles

When it comes to bending aluminum angles, selecting the right technique is key. Typically, roll bending and press brakes are the most commonly used options due to their ability to provide even bends and high precision. For large radii or multiple angle transitions, rotary bending is a better choice. For small-scale production or simpler applications, manual bending and push bending offer quick and cost-effective solutions.

4.0How to Manually Bend Aluminum

✅ Preparation

Clean the material surface and gather basic tools such as a ruler, marker, C-clamps, vise, and hammer. If the material is thick, preheating may be necessary to increase its ductility.

✅ Process

- Mark the Bending Line: Use a ruler and marker to mark the bend. If needed, drill small auxiliary holes along the bend line or use a milling cutter to process the surface, which will help with the bending process.

- Secure the Workpiece: Use C-clamps or a vise to firmly hold the material in place.

- Apply Even and Slow Pressure: Gently tap along the bending line with a hammer, starting from one end and working towards the other. Bend in increments of 10-20 degrees.

- Check the Bending Angle: If the bend is insufficient, make adjustments as needed.

5.0How to Use a Press Brake for Bending

✅ Preparation

Clean the workpiece surface and gather the press brake, die, and measuring tools.

✅ Process

- Place the Workpiece: Position the workpiece against the backstop and align it properly.

- Adjust the Die: Ensure the die and punch are aligned correctly. For 90º bends, it is recommended to use an 88º die to compensate for material springback.

- Apply Pressure Slowly: Apply pressure gradually to avoid excessive force. If you hear unusual noises or notice unstable movement, stop the machine immediately and check for issues.

- Check the Bending Angle: After each bend, use measuring tools to check the angle. If any deviations are found, make minor adjustments as necessary.

6.0Best Materials for Aluminum Bending

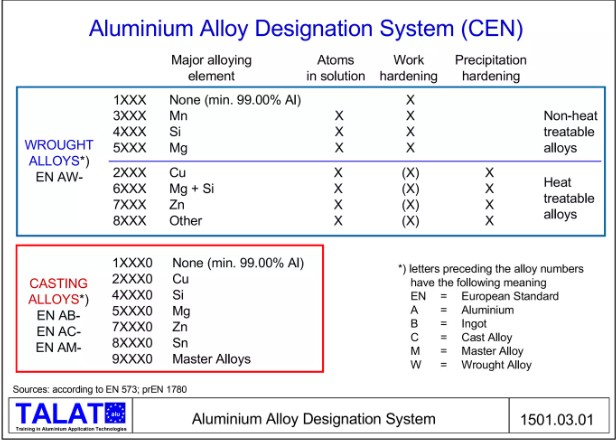

The bending performance of aluminum alloys is influenced by their alloy composition and temper condition. The most suitable alloy series for bending are the 3XXX, 5XXX, and 6XXX series. Alloys in the 2XXX series should be avoided due to their high hardness, which makes forming more difficult. Nevertheless, with proper temper treatment, these alloys can still be successfully bent.

6.1Best Four Aluminum Alloys for Bending

- 3003 Aluminum Alloy:3003 is one of the best choices for bending, offering good strength, excellent cold-working properties, and a significant gap between yield and tensile strength — all of which contribute to its ability to perform exceptionally during bending.

- 5052 Aluminum Alloy:5052 offers high ductility and a substantial gap between yield and tensile strength. It also shows strong corrosion resistance, especially in marine or other corrosive environments. After annealing, its formability surpasses even 3003, making it a preferred choice for complex bends.

- 5083 Aluminum Alloy:5083 is widely used in shipbuilding due to its resistance to corrosion and strong weldability. To maximize its bending performance, it’s recommended to use 5083 in its H111, H112, or O condition.

- 6061 and 6082 Aluminum Alloys: These two are heat-treatable alloys with desirable strength and formability. While their bending performance is poor in T4 or T6 condition, they can be successfully formed in T4 condition and subsequently aged to T6 for additional strength.

6.2Aluminum Temper Treatments

Alloy selection should account for both its composition and its temper condition, along with the thickness of the material. Proper understanding of these factors helps you choose the most appropriate material and bending method, ensuring high product quality.

Temper Treatments and Their Characteristics:

- T (Heat Treated)

Alloys in T6 and T651 condition (such as 6XXX series) have high strength and medium formability — ideal for applications requiring both toughness and resistance. However, care must be taken during bending to avoid cracking due to reduced ductility. - H (Strain Hardened)

Alloys in H14 or H24 condition have undergone strain hardening, increasing their strength. These tempers are suitable for medium-angle bending without cracking. - O (Annealed)

O condition denotes a fully annealed state, offering maximum formability — perfect for simple bending operations — but with somewhat lower strength. - F (As-Fabricated)

F condition refers to as-fabricated material with lower strength but greater flexibility and resiliency.

7.0Key Factors Affecting Aluminum Bending

The bending process for aluminum is influenced by several key factors, which directly determine both bending quality and formability.

- Formability: Formability refers to a material’s ability to undergo permanent deformation without cracking or tearing. It’s influenced by the material’s strength, ductility, shape, and thickness. Standard tests, like ASTM E2218, help gauge formability and identify which alloys are most suitable for bending.

- Thickness and Bend Radius: Thickness and bend radius significantly affect bending performance. Thinner materials are easier to bend, while thick plate bending is more challenging. Small bending radii may cause cracking, so following manufacturer guidelines is crucial.

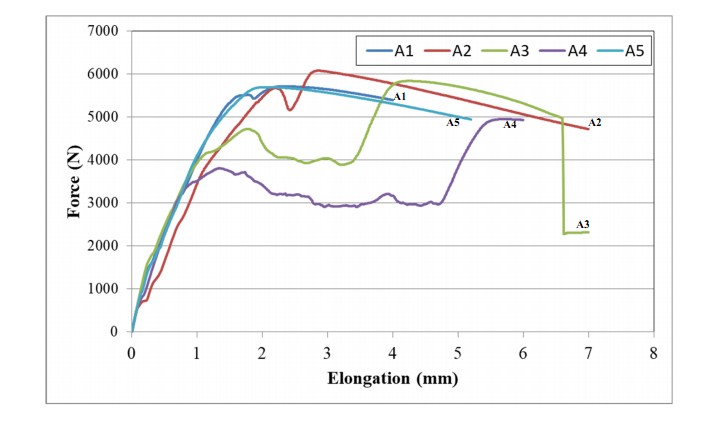

- Elongation : Elongation measures a material’s ability to stretch under tension — higher elongation means greater formability. For example, annealed 3003 (AA3003-O) with an elongation of about 35% is well-suited for bending applications. The stress-strain curve can aid in choosing the most appropriate alloy.

8.0How to Prevent Cracks During Aluminum Bending

Aluminum can crack during bending, especially after anodizing. Manufacturers often face the challenge of bending without causing damage. Here are 8 key preventive measures:

- Choose the Right Grade and Temper: Select a grade and temper that’s suitable for bending. The alloy’s composition and hardness directly affect its formability — choosing the appropriate material can significantly reduce the risk of cracking.

- Use Proper Bending Equipment: Choose equipment designed for your material and bending requirements to avoid stress concentration and localized damage.

- Increase the Bend Radius: A larger bend radius helps evenly distribute stress and reduce the likelihood of cracking.

- Fill Voids in the Bending Area: Using metal inserts or padding during bending prevents localized stress and collapse, reducing the chance of cracks.

- Adjust Thickness or Tension: Increasing material thickness or reducing bending tension helps keep stress more evenly dispersed.

- Adjust Die Gap and Material: Improve die gap and select appropriate die materials to avoid surface damage and subsequent fractures.

- Use Smooth Bends Instead of Sharp Corners: Gradually bending instead of making sharp bends prevents stress concentration and reduces the risk of cracking.

- Apply Lubrication to Reduce Frictinal Stress: Applying a lubricant during bending can reduce friction and ease stress on the material’s surface.

References:

ahssinsights.org/forming/forming-modes/bending/

www.researchgate.net/publication/348823039_Buckling_and_bending_properties_of_aluminium_plate_with_multiple_cracks