- 1.0What Is 6061 Aluminum Alloy?

- 2.0Common Applications of 6061 Aluminum Alloy

- 3.06061 Aluminum Strength Comparison With Other Aluminum Alloys

- 4.0How to Process 6061 Aluminum Alloy

- 5.0How to Properly Weld 6061 Aluminum Alloy

- 6.0Is 6061 Aluminum Suitable for Structural or Load-Bearing Applications?

- 7.0Does 6061 Aluminum Offer Good Corrosion Resistance?

- 8.0Can 6061 Aluminum Be Anodized?

- 9.0Why Choose 6061 Instead of 5052 or 7075 Aluminum Alloy?

- 10.0Heat Treatment of 6061 Aluminum (T6, T651)

6061 aluminum alloy is one of the flagship heat-treatable alloys in the 6000 series. Designated by the Aluminum Association (AA) with the UNS number A96061, it is positioned as a “versatile, cost-effective general-purpose alloy.” With magnesium (Mg) and silicon (Si) as its primary alloying elements, it offers significant strength improvement through heat treatment while delivering excellent corrosion resistance, machinability, weldability, and formability.

As a result, it is one of the most widely used aluminum alloys in industrial applications and is often regarded as a true “all-rounder.”

1.0What Is 6061 Aluminum Alloy?

6061 aluminum is a heat-treatable Al-Mg-Si alloy (a core grade in the 6xxx series). It uses magnesium (Mg) and silicon (Si) as its main alloying elements, with small additions of copper (Cu) and chromium (Cr). The balance is aluminum (Al).

1.1Why 6061 Is Widely Preferred

- Balanced mechanical properties: Moderate strength (typical tensile strength 200–310 MPa) with good toughness. Strength can be significantly increased through T6 heat treatment to meet general structural requirements.

- Excellent machinability: Suitable for cutting, drilling, bending, and welding (TIG and MIG). Works well with aluminum cutting equipment and supports complex forming processes.

- Strong corrosion resistance: Forms a dense natural oxide layer and supports anodizing or coating, making it suitable for outdoor or humid environments.

- High cost-performance ratio: Readily available raw materials, mature processing technology, and lower cost compared to high-strength alloys like 7075.

- Lightweight characteristics: Density of about 2.7 g/cm³ (one-third that of steel), ideal for lightweight design in aerospace, automotive, and construction.

Applications include machinery components, architectural panels, automotive parts, aerospace fittings, and electronic equipment frames.

1.2Mechanical Properties of 6061 Aluminum Alloy

| Property | Unit | O Temper (Annealed) | T4 Temper (Solution + Natural Aging) | T6 Temper (Solution + Artificial Aging) | Notes |

| Tensile Strength (σb) | MPa | ≥110 | ≥240 | ≥290 | T6 is the most commonly used high-strength condition |

| Yield Strength (σ0.2) | MPa | ≥35 | ≥140 | ≥240 | Yield strength defines load-bearing capability |

| Elongation (δ5) | % | ≥25 | ≥12 | ≥8 | Higher values indicate better ductility and workability |

| Brinell Hardness (HB) | – | ≤30 | ≤65 | ≤95 | Hardness correlates with cutting difficulty |

| Density (ρ) | g/cm³ | 2.70 | 2.70 | 2.70 | Density remains constant across all tempers |

| Elastic Modulus (E) | GPa | 69 | 69 | 69 | Key stiffness indicator for structural design |

1.3Key Feature Summary

- Significant heat-treat response: T6 strength is more than double that of the O temper, suitable for structural components.

- Strength–ductility balance: Even in T6, elongation ≥8%, supporting bending and stamping applications.

- Stable performance: Density and modulus remain unchanged across tempers, simplifying engineering design.

- Machining-friendly: Moderate hardness (HB ≤95 in T6) supports precise cutting and drilling using aluminum cutting equipment.

1.4Chemical Composition of 6061 Aluminum Alloy

| Category | Element | Content Range | Notes |

| Major Alloying Elements | Mg | 0.80–1.20 | Forms Mg₂Si strengthening phase |

| Si | 0.40–0.80 | Key element for heat-treat strengthening | |

| Cu | 0.15–0.40 | Enhances strength and corrosion resistance | |

| Cr | 0.04–0.35 | Grain refinement and improved stress-corrosion resistance | |

| Impurities (Max) | Fe | ≤0.70 | Excess may reduce surface quality and machinability |

| Mn | ≤0.15 | Controlled to avoid corrosion issues | |

| Zn | ≤0.25 | Residual impurity; kept low | |

| Ti | ≤0.15 | Helps refine grain structure | |

| Other Impurities | Single ≤0.05, total ≤0.15 | Ensures alloy purity | |

| Base Element | Al | Balance | Provides primary mechanical properties |

1.5Key Notes

- Optimized Mg+Si ratio enables Mg₂Si precipitation during T6 heat treatment to achieve high strength.

- Strict impurity control (especially Fe) prevents formation of brittle phases and ensures good machinability and weldability.

- Balanced chemical composition provides the foundation for its combined strength, corrosion resistance, and processing performance.

2.0Common Applications of 6061 Aluminum Alloy

2.1Machinery Manufacturing

- General mechanical components: gears, shafts, brackets, bases

- Automation equipment frames and conveyor assemblies

- Custom machined parts produced via cutting or bending equipment; mold bases

2.2Construction and Building Materials

- Curtain wall systems, window and door profiles, railings and handrails

- Sunroom frames and decorative panels (suitable for anodized coloring)

- Structural components for bridges and public facilities (lightweight + corrosion resistance for outdoor use)

2.3Transportation Industry

- Automotive parts: body frames, wheels, engine brackets, radiators

- Aerospace components: wing structures, fuselage elements, luggage racks

- Interior parts for rail transit; anti-slip decking for marine vessels

2.4Electronics and Home Appliances

- Electronic device frames: PC cases, monitor brackets

- Appliance housings: air conditioner frames, refrigerator trim

- Heat sinks and cooling components (excellent thermal conductivity and machinability)

2.5Other Fields

- Medical devices: wheelchair frames, rehabilitation equipment components

- Sporting goods: bicycle frames, skis, trekking poles

- Pressure vessels and piping systems (suitable for medium/low-pressure applications)

2.6Application Logic

All applications benefit from its balanced machinability, lightweight characteristics, and corrosion resistance. It is particularly suitable for high-precision processing using aluminum cutting machines and welding equipment, making it one of the most widely utilized general-purpose alloys.

3.06061 Aluminum Strength Comparison With Other Aluminum Alloys

| Alloy | Series | Common Temper | Tensile Strength Range | Strength Level | Key Features (vs. 6061) |

| 1100 | 1xxx | H14 | 95–120 MPa | Very Low | Lowest strength; used for decorative or conductive parts; excellent workability but poor load-bearing capability |

| 3003 | 3xxx | H18 | 160–180 MPa | Low | Slightly stronger than pure aluminum; good corrosion resistance; non-heat-treatable; ideal for stamped parts |

| 5052 | 5xxx | H32 | 210–230 MPa | Low–Medium | Strength close to 6061-O/T4; superior corrosion resistance, especially in marine environments; non-heat-treatable |

| 6061 | 6xxx | T6 | 290–310 MPa | Medium | Heat-treatable; balanced strength, machinability, and cost |

| 6063 | 6xxx | T6 | 240–260 MPa | Medium | Slightly lower strength; better formability and weldability; ideal for extruded profiles such as doors and windows |

| 7075 | 7xxx | T6 | 480–510 MPa | Very High | High-strength alloy; approx. 1.6× stronger than 6061-T6; lower machinability, higher cost, moderate corrosion resistance |

| 2024 | 2xxx | T3 | 420–480 MPa | High | Higher strength than 6061; used in high-stress aerospace applications; lower corrosion resistance (requires cladding) |

3.1Key Conclusions

- 6061 aluminum (especially T6) is a medium-strength alloy, significantly stronger than 1xxx, 3xxx, and non-heat-treatable 5xxx alloys.

- Although lower in strength than 7xxx and 2xxx alloys, it offers far better machinability (cutting, welding, bending) and cost efficiency, and can be processed using standard aluminum cutting equipment.

- Compared with 6063, 6061 offers higher strength and is more suitable for structural components, while 6063 is optimized for extrusion and architectural profiles.

3.2Application Guidance

- For general structural components: 6061

- For high-pressure/heavy-load aerospace parts: 7075/2024

- For corrosion-critical and marine environments: 5052/5083

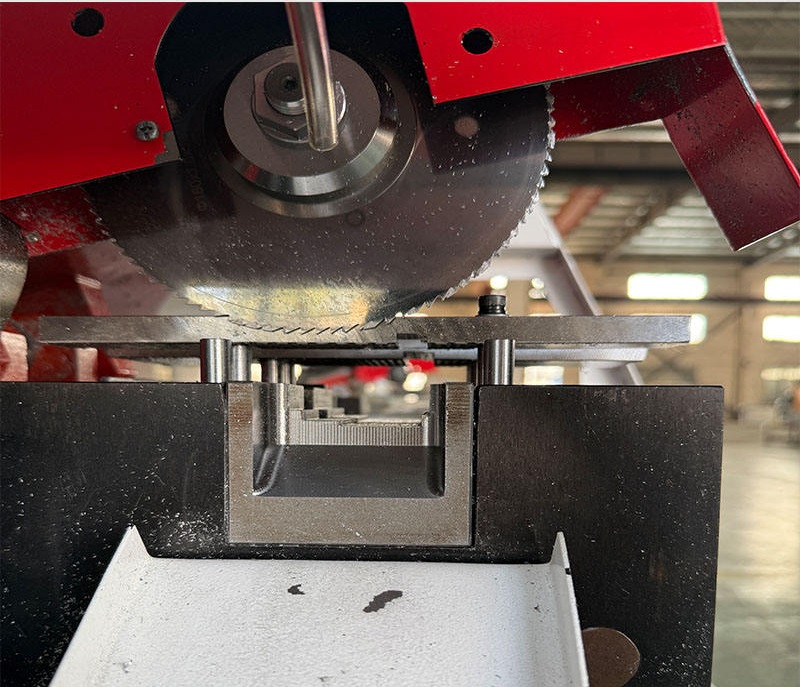

4.0How to Process 6061 Aluminum Alloy

4.1Material Preparation

Prior to precision machining, the accuracy of raw material cutting directly affects subsequent fixturing and positional alignment.

4.2Equipment Selection

For precision length-cutting of bars, tubes, and extruded profiles, a CNC aluminum cutting machine is essential. Compared with conventional saws, CNC systems offer the following advantages:

- High-speed spindle (3000–5000 RPM)

- Servo-controlled feeding, maintaining length tolerances within ±0.1 mm

- Compatible with ultra-thin carbide blades (minimizes kerf loss, delivers clean cutting surfaces, often eliminating secondary face-milling)

4.3Cooling & Lubrication

- Adopt micro-lubrication (MQL) systems combined with aluminum-specific cutting oils

- Prevent chip adhesion on the blade during the cutting process

4.4CNC Machining Strategy

6061 aluminum tends to be “soft and gummy,” making it susceptible to built-up edge (BUE). Therefore, the machining strategy centers on high cutting speeds, large chip evacuation volume, and sharp cutting geometry.

Tooling

| Parameter | Specifications |

| Tool Material | Fine-grain carbide (YG grade) |

| Coatings | Preferred: Uncoated (highly polished/bright-finish) or DLC-coated tools; Avoid: TiAlN (aluminum-containing coatings) |

| Flute Count | 2-flute or 3-flute (for milling, provides larger chip pockets) |

| Helix Angle | ≥45° (enhances cutting smoothness and chip flow) |

Cutting Parameters

| Parameter | Range/Requirement |

| Cutting Speed (Vc) | 150–400 m/min (adjustable based on machine rigidity; higher speeds acceptable) |

| Feed per Tooth (fz) | Relatively high feed rate (ensures cutting instead of rubbing; avoids work-hardening) |

| Depth of Cut (ap/ae) | Roughing: Heavy cuts allowed; Finishing: Leave 0.1–0.2 mm stock for high-speed light passes |

4.5Key Challenges & Solutions

Deformation Control

6061 retains significant internal stress, leading to warping in thin-wall parts or high material removal ratio components.

- Process sequence: Rough machining → Stress relief/natural aging → Finish machining

- Workholding: Use soft jaws or vacuum fixtures during finishing (minimizes elastic deformation from clamping forces)

Chip Adhesion & Built-up Edge

- Coolant requirement: High-pressure, high-flow emulsified coolant (8–10% concentration)

- Functions: Cooling, chip evacuation assistance, reduces recutting/chip compaction in flutes

Surface Finishing

6061 aluminum is highly suitable for anodizing. Standard process:

- Post-machining sandblasting (masks tool marks)

- Anodizing treatment:

- Type II: Natural/colored anodizing

- Type III: Hard anodizing (enhances wear resistance and aesthetics)

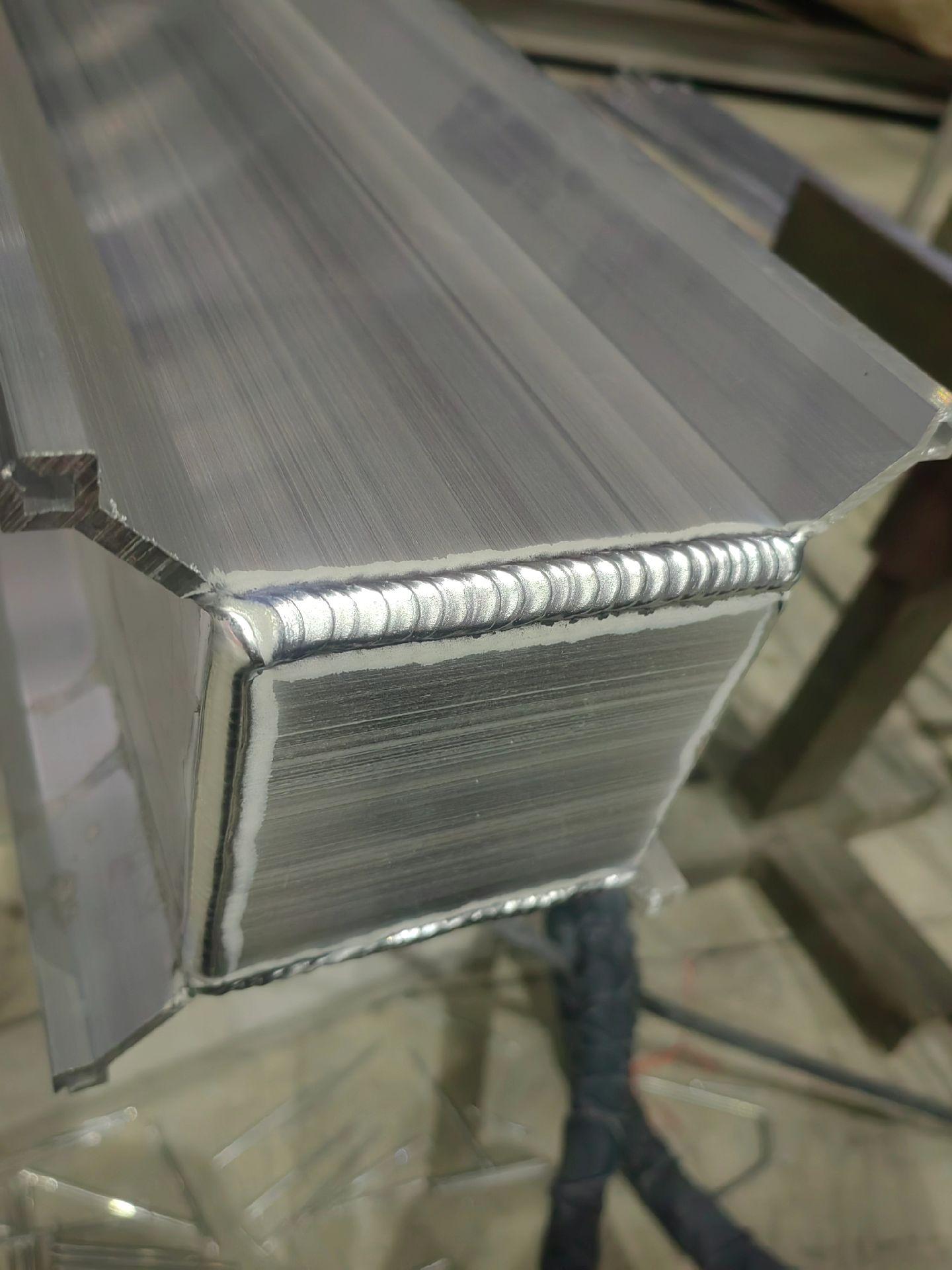

5.0How to Properly Weld 6061 Aluminum Alloy

5.1Essential Preparations Before Welding

- Surface Cleaning: Remove the oxide layer (Al₂O₃) from the joint area using a stainless-steel wire brush or abrasive paper, then wipe off oil or contaminants with acetone or alcohol to prevent porosity and lack of fusion.

- Filler Metal Selection: Prefer ER5356 (better crack resistance) or ER4043 (better fluidity) to match the Mg-Si chemistry of 6061.

- Preheating Requirements: Preheat to 80–120°C for plate thickness greater than 6 mm; thin sections (≤6 mm) typically require no preheating to avoid thermal distortion.

- Equipment Choice: TIG (GTAW) or MIG (GMAW) is recommended; shielded metal arc welding should be avoided.

5.2Key Welding Parameters (Reference Values)

| Welding Method | Thickness (mm) | Current (A) | Voltage (V) | Shielding Gas | Welding Speed (mm/min) |

| TIG | 1–3 | 60–100 | 10–14 | Pure Ar, 8–12 L/min | 50–100 |

| TIG | 4–8 | 100–150 | 14–18 | Pure Ar, 10–15 L/min | 80–120 |

| MIG | 3–12 | 120–200 | 18–24 | Pure Ar, 15–20 L/min | 100–150 |

5.3Welding Operation Guidelines

- Shielding Gas: Use pure argon throughout the weld; maintain a nozzle-to-work distance of 3–5 mm to prevent air intrusion and porosity.

- Welding Sequence: Weld from the center outward in segments using skip welding or a symmetrical sequence to minimize residual stress and distortion.

- Welding Technique: Apply low-current, fast-travel welding to avoid overheating, as 6061 is susceptible to hot cracking. Taper off slowly at the weld end to fully fill the crater.

- Joint Design: Prefer butt or fillet joints; avoid lap joints, which are prone to slag entrapment. Maintain a joint gap of 0.5–1.5 mm.

5.4Post-Weld Treatment

- Surface Cleaning: After cooling, remove spatter and inspect the joint to ensure no porosity or cracking is present.

- Corrosion Protection: Apply anodizing if enhanced corrosion resistance is required.

- Quality Verification: Critical structural components should undergo non-destructive testing such as dye-penetrant inspection.

6.0Is 6061 Aluminum Suitable for Structural or Load-Bearing Applications?

Core Conclusion: Suitable for medium-load structures; not recommended for extreme heavy-load applications.

6.1Key Reasons It Is Suitable

- Adequate Strength (T6 Condition Required): Tensile strength of 290–310 MPa and yield strength of around 240 MPa meet the needs of most general structural applications such as equipment frames, brackets, and secondary beams.

- Balanced Mechanical Properties: Offers a good balance of strength and toughness; better impact resistance than high-strength alloys like 7075, reducing the risk of brittle failure.

- Lightweight Advantage: Density of 2.7 g/cm³ makes it about 60% lighter than steel, supporting lightweight designs in aerospace, automotive, and machinery applications.

- Ease of Fabrication: Good weldability and machinability, compatible with precision cutting and both bolted and welded assemblies for complex structures.

6.2Typical Applications

- Mechanical equipment frames, conveyor support beams, machine tool bases

- Architectural structures such as sunroom frames, stair railings, and secondary supports

- Transportation components including automotive frames, marine deck supports, and aerospace sub-structures

- General structural uses such as racks, workstations, and industrial barriers

6.3Limitations and Considerations

- Not Recommended For: Primary bridge structures, heavy machinery core load components, or aerospace landing gear, which require higher-strength alloys such as 7075 or 2024.

- Critical Requirements:

- Must be used in the T6 temper; O/T4 tempers do not provide adequate strength

- Stress relief may be required after welding due to localized strength reduction

- Outdoor applications should be anodized or coated to protect against corrosion

- Design Considerations: Structural design must follow engineering load calculations, avoid stress concentration, and incorporate reinforcement where necessary.

7.0Does 6061 Aluminum Offer Good Corrosion Resistance?

7.1Key Advantages in Corrosion Resistance

Natural Protection: A dense Al₂O₃ oxide layer forms naturally on the surface, providingstrong protection against atmospheric, freshwater, and mildly alkaline or acidic environments.

- Optimized Alloy Composition: Trace chromium improves grain refinement and resistance to stress-corrosion cracking, reducing post-processing corrosion risks from cutting or welding.

- Enhanced Protection Options: Anodizing, coating, or electrophoretic deposition can further thicken the protective layer, significantly improving performance in outdoor or humid environments.

7.2Environmental Performance and Limitations

| Environment | Corrosion Resistance | Notes |

| Atmospheric / Freshwater | Excellent with no significant long-term corrosion | Natural oxide film is typically sufficient |

| Mild Acids / Alkalis (pH 4–9) | Good short-term resistance | Avoid prolonged immersion; clean surface contaminants promptly |

| Marine / Salt Spray | Moderate; susceptible to pitting and crevice corrosion | Anodizing with sealing is essential; 5052/5083 may be preferred |

| Strong Acids / Chemical Media | Poor; readily attacked | Not recommended without specialized coatings |

8.0Can 6061 Aluminum Be Anodized?

6061 aluminum can be anodized very effectively and is one of the most widely used anodizable alloys in industrial applications. As a heat-treatable alloy in the 6000 series (Mg-Si system), its chemistry and microstructure support the formation of a durable, corrosion-resistant, and wear-resistant anodic oxide layer while also providing excellent aesthetic possibilities.

8.1Core Reasons for Anodizing Compatibility

- Stable Composition: Magnesium (0.8–1.2 wt%) and silicon (0.4–0.8 wt%) contents are well balanced, while impurities such as iron (≤0.7 wt%) and copper (≤0.15 wt%) are controlled to avoid interference with oxide-film formation. This ensures a uniform and dense anodic layer.

- Favorable Microstructure: After solution treatment and artificial aging (e.g., T6 temper), the grain structure becomes uniform, and Mg₂Si particles are well distributed, enabling a strong bond between the anodic film and the substrate.

8.2Typical Process Parameters

| Process Step | Key Parameters |

| Pretreatment | Alkaline cleaning (5–10% NaOH, 40–60°C, 1–3 min) → Neutralizing (10–15% HNO₃, room temperature, 30 s) → Rinse |

| Anodizing | Sulfuric acid electrolyte (15–20% H₂SO₄), 18–22°C, 12–18 V, 20–60 min |

| Film Thickness | Type II: 5–25 µm; Type III hard anodizing: 50–100 µm |

| Post-Treatment | Hot-water sealing or nickel-salt sealing (95–100°C, 15–30 min), optional dyeing |

8.3Performance Improvements After Anodizing

- Corrosion Resistance: The dense Al₂O₃ layer blocks air, moisture, and corrosive agents, reducing the corrosion rate of 6061 in harsh environments (such as marine exposure) to below 0.05 mm/year.

- Surface Hardness: Typical anodized films reach 200–300 HV, while hard-anodized coatings can reach 400–500 HV, significantly improving wear resistance for components requiring frequent contact or sliding.

- Aesthetic Options: The porous structure of the anodic film accepts dyes effectively, offering stable and fade-resistant colors suitable for architectural and electronic applications.

9.0Why Choose 6061 Instead of 5052 or 7075 Aluminum Alloy?

6061 aluminum is widely selected for industrial applications due to its balanced property profile. It offers medium strength achievable through heat treatment, excellent machinability and weldability, solid corrosion resistance, and cost efficiency. This combination allows 6061 to perform well across most non-extreme service conditions. In contrast, 5052 (non-heat-treatable) and 7075 (ultra-high-strength) serve narrower application niches and cannot meet multi-dimensional requirements for general-purpose engineering projects.

9.1Comparative Performance Table

| Performance Category | 6061-T6 | 5052-H32 | 7075-T6 | Advantage of 6061 |

| Tensile Strength | 310 MPa (45 ksi) | 230 MPa (33 ksi) | 570 MPa (83 ksi) | Medium strength meets 80% of structural needs without the cost burden of excess strength |

| Yield Strength | 275 MPa (40 ksi) | 195 MPa (28 ksi) | 500 MPa (73 ksi) | Stable, heat-treated strength suitable for dynamic loads such as automotive suspension arms |

| Corrosion Resistance (Salt Spray) | Excellent (≤0.08 mm/year) | Superior (≤0.05 mm/year) | Moderate, prone to stress-corrosion cracking | Adequate outdoor/mild marine resistance without heavy protective treatments |

| Weldability (MIG/TIG) | Excellent (≈85% weld strength retention) | Good (≈75%) | Poor, crack-sensitive and requires specialized procedure | Ideal for modular assemblies; no post-weld heat treatment required |

| Machinability (Cutting Speed) | Good (≈800 m/min) | Moderate (≈600 m/min, tendency to gall) | Poor (≈500 m/min, fast tool wear) | High machining efficiency and low scrap rate for mass production |

| Heat Treatability | Yes (T6/T4 with strength variability) | No (cold-work only) | Yes (very high strength in T6) | Flexible strength tuning through heat treatment improves design adaptability |

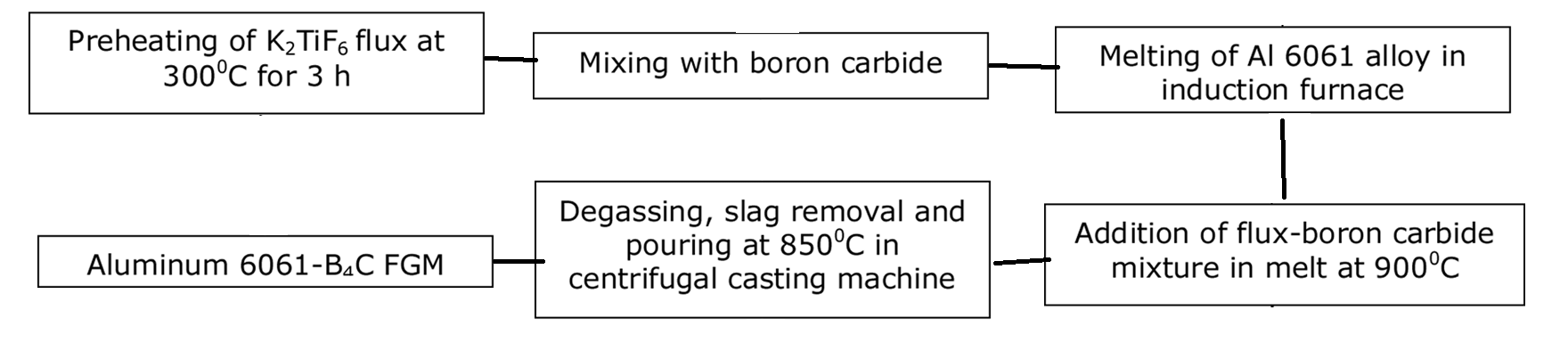

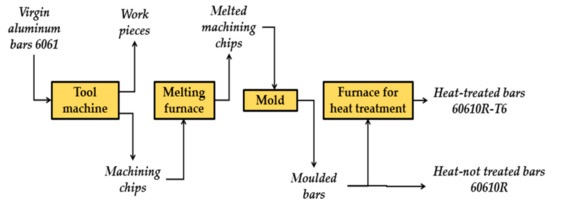

10.0Heat Treatment of 6061 Aluminum (T6, T651)

As a typical heat-treatable alloy of the 6000 series, 6061 achieves strength through a combination of solution treatment, quenching, and aging. This process promotes the formation of Mg₂Si strengthening precipitates, significantly increasing strength and hardness while maintaining machinability and corrosion resistance. T6 and T651 are the most common tempers: T6 maximizes strength, while T651 prioritizes dimensional stability.

10.1Core Principles of Heat Treatment

- Solution Treatment: The alloy is heated to a high temperature to dissolve Mg₂Si and other precipitates into the aluminum matrix, forming a uniform supersaturated solid solution.

- Rapid Quenching: Fast cooling locks in the supersaturated state and prevents premature precipitation, enabling subsequent aging hardening.

- Aging (Natural or Artificial): Controlled precipitation of fine, dispersed Mg₂Si particles strengthens the alloy by pinning dislocations.

Note: Temperature and time must be controlled precisely to avoid overheating (grain coarsening) or under-aging (insufficient strength).

10.2T6 and T651 Heat Treatment Processes

T6 Temper (Solution Treatment + Artificial Aging) — Maximum Strength

Suitable for structural components requiring high load capacity.

| Process Stage | Key Parameters | Purpose |

| Pretreatment | Alkaline cleaning (5–10% NaOH, 40–60°C, 1–3 min) → Neutralizing (10% HNO₃, 30 s) | Remove oil and oxide to ensure uniform solution treatment |

| Solution Treatment | 530–540°C (±5°C), 1–2 hours (1 hr for ≤20 mm; 1.5–2 hr for 20–50 mm) | Fully dissolve Mg₂Si and achieve a supersaturated solution |

| Quenching | Water quench (≤30°C), immersion within 10 s, cooling rate ≥150°C/min | Preserve the supersaturated state |

| Artificial Aging | 170–175°C (±3°C), 8–12 hours | Controlled precipitation to reach peak strength |

| Cooling | Air cool to room temperature | Stabilize the precipitate distribution |

Typical Mechanical Properties for 6061-T6 (per ASTM B221):

- Tensile Strength: 310 MPa (45 ksi)

- Yield Strength: 275 MPa (40 ksi)

- Elongation (50 mm): 17%

- Brinell Hardness: 95 HB

T651 Temper (Solution + Stress Relief Stretching + Artificial Aging) — High Dimensional Stability

T651 is an optimized version of T6. A stress-relief stretching step is added after quenching to eliminate residual stress, ideal for precision components such as aerospace extrusions and machine-way systems.

| Process Stage | Key Parameters | Purpose |

| Pretreatment → Solution Treatment → Quenching | Identical to T6 | Achieve supersaturation for aging |

| Stress-Relief Stretching | Tensile stretch of 1–3% (1–2% for extrusions, 2–3% for plates); 5–10 mm/min | Release quench-induced residual stress and minimize deformation |

| Artificial Aging | Same as T6 (170–175°C, 8–12 hours) | Reach peak strength with improved stability |

| Straightening | Minor correction as needed | Maintain tight dimensional tolerances (e.g., straightness ≤0.1 mm/m) |

Advantages of T651:

- Residual stress ≤50 MPa (over 60% lower than T6)

- Excellent dimensional stability; machining distortion ≤0.05 mm/m

- High uniformity of mechanical properties, with ≤5% variation across sections

10.3Key Differences Between T6 and T651

| Category | T6 | T651 |

| Process Difference | No stress-relief stretch | Includes 1–3% stretching after quench |

| Residual Stress | High (≈120–150 MPa) | Very low (≤50 MPa) |

| Dimensional Stability | Moderate; prone to distortion | Excellent; suitable for precision machining |

| Typical Applications | General structural components (brackets, housings, tubing) | Precision parts (aerospace shapes, machine guides) |

| Production Time | Shorter | Longer due to stretching and straightening |

| Cost | Baseline (1.0) | Higher (1.2–1.3) |

Reference:

titanium.com/alloys/aluminum-alloys/aluminum-alloy-6061/

asm.matweb.com/search/specificmaterial.asp?bassnum=ma6061t6