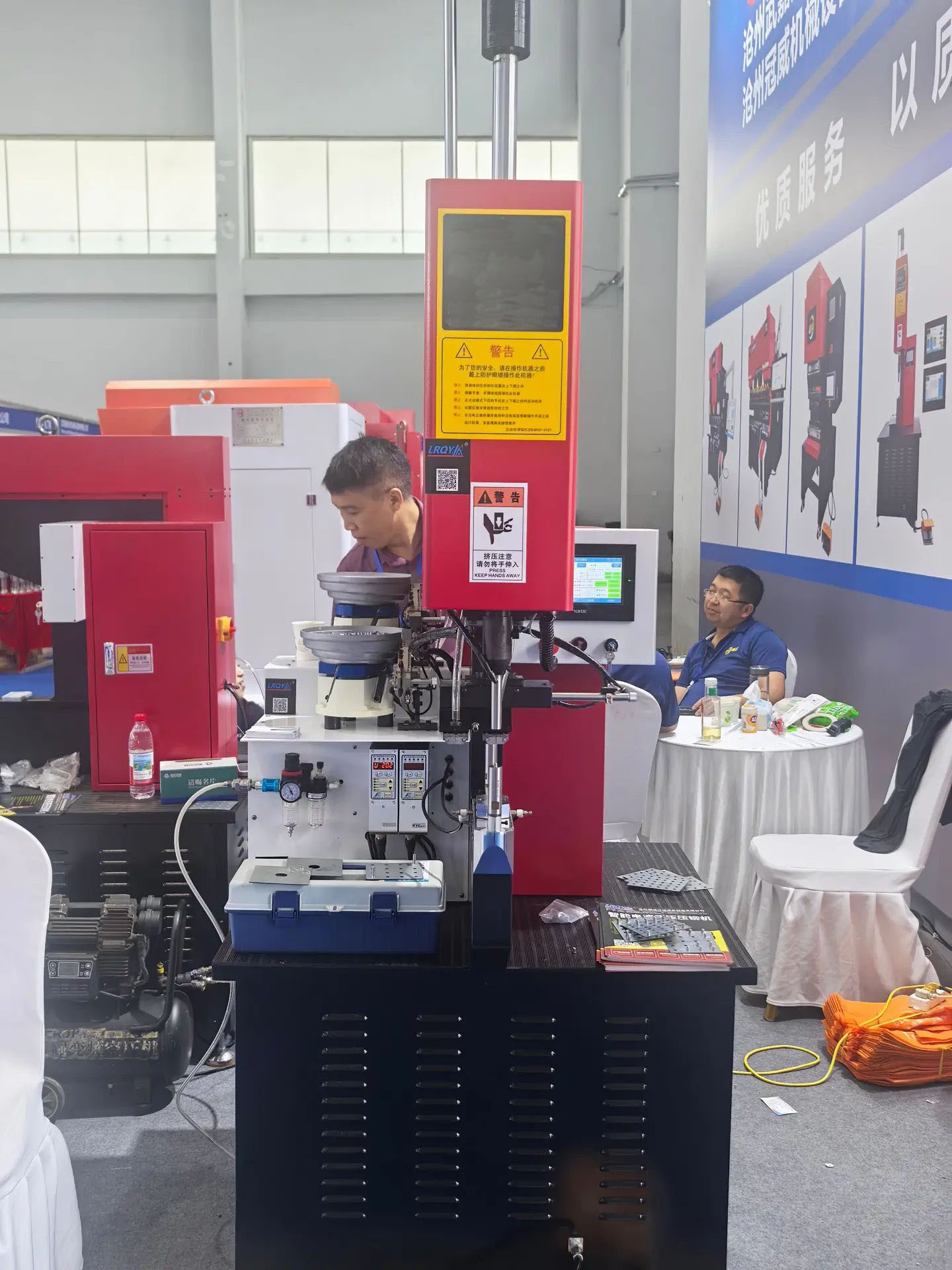

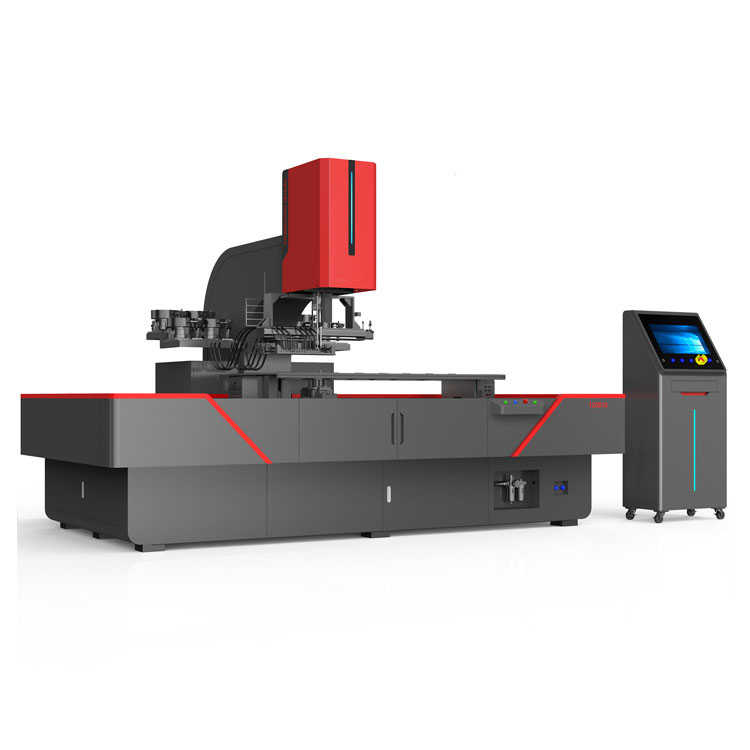

Multi-Station Automatic Hydraulic Riveting Machine– Machine photos

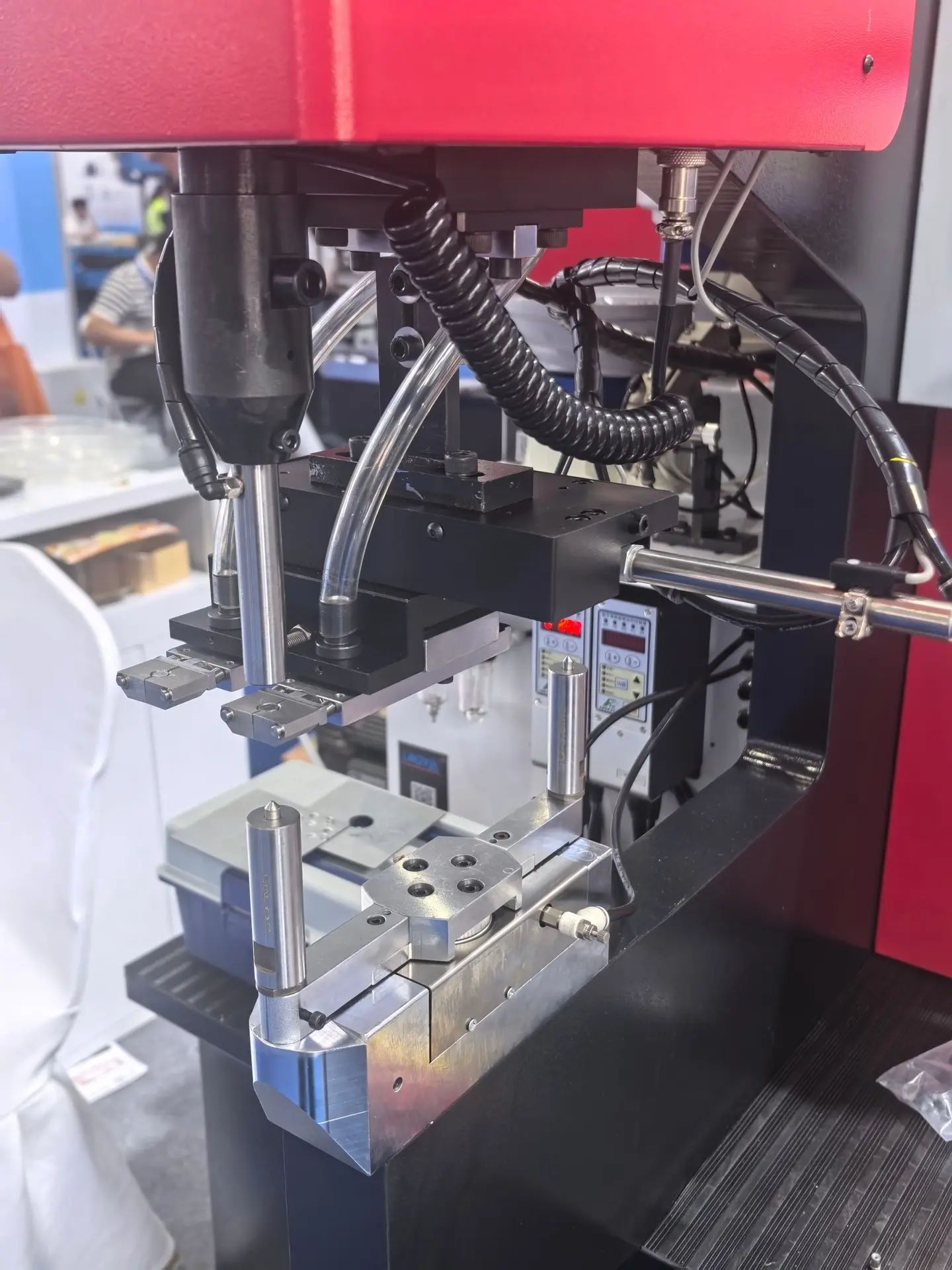

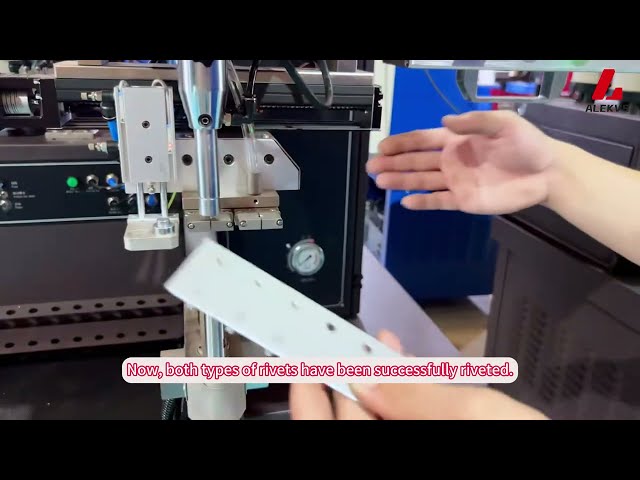

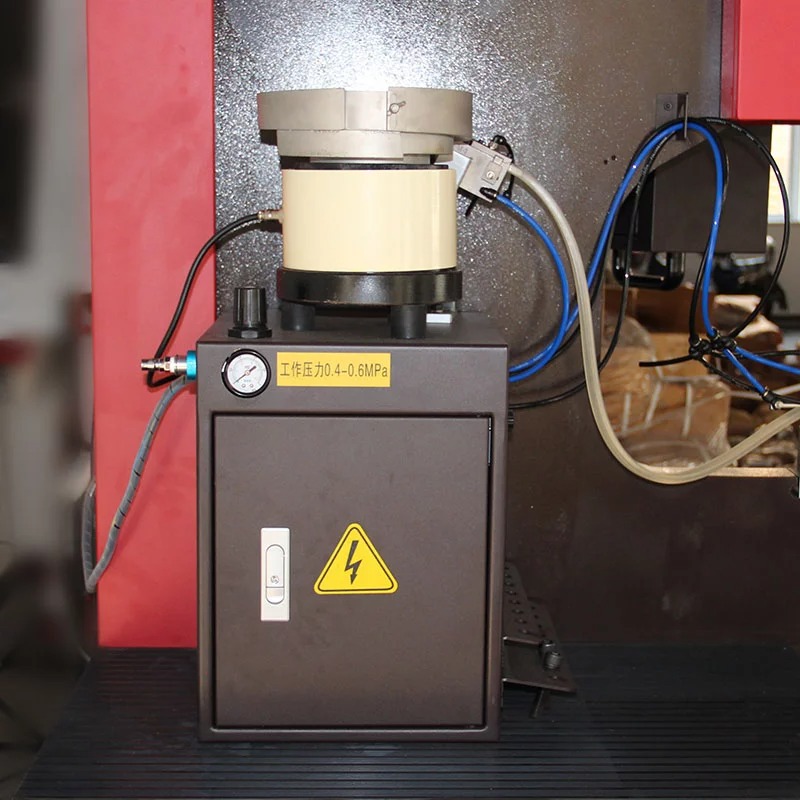

Auto Feed Riveting and Fastener Insertion Machine-detail photos

Hydraulic and Power System Advantages

- Dual-Pump Design: The high-pressure pump controls speed while the low-pressure pump assists in increasing pressure. When flow demand is low, the small pump can operate independently, ensuring efficient system performance.

- Adjustable Speed: Prevents excessive oil temperature and ensures stable hydraulic system operation.

- ECO Energy-Saving Mode: When not riveting, the machine’s motor automatically shuts down after 10 minutes, saving energy and reducing environmental impact.

Safety Protection System

- Comprehensive Safety Protection: The machine protects operators in both conductive and non-conductive modes, significantly reducing safety risks and enhancing operator confidence and efficiency.

Die and Die-Changing System

- Upper Die System: Uses a servo screw module for free switching. The upper die heads are highly compatible, requiring only three types to meet different production needs, improving flexibility and efficiency.

- Lower Die System: Cylinder-driven rotation allows dual lower dies to switch freely, enhancing riveting efficiency.

- Automatic Lower Die Changing Device: Composed of a lower die storage and retrieval mechanism, both using servo motors, screws, and linear guides for fast, precise movement, accurately positioning dies at the designated storage points.

- Lower Die Operation: Cylinders efficiently eject or retract the lower die, while the retrieval mechanism quickly delivers it to the correct position, enabling fast die changes.

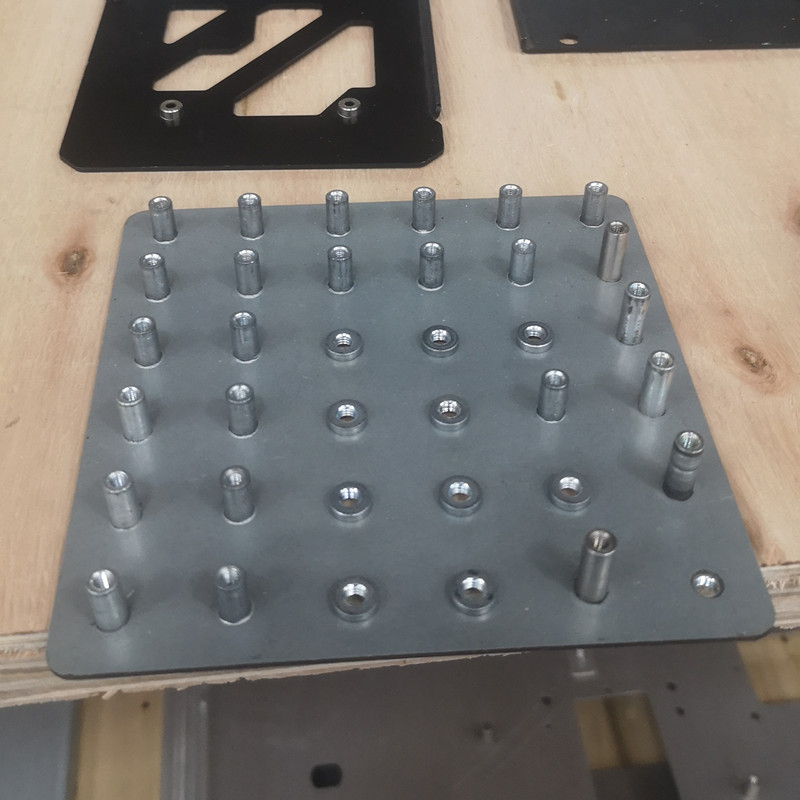

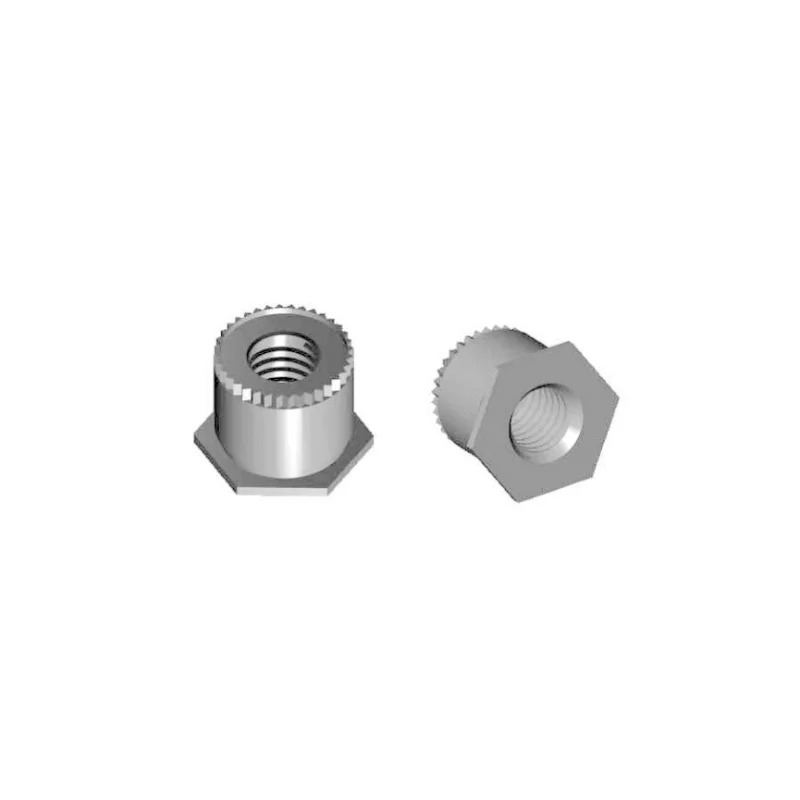

Multi-Station Automatic Hydraulic Riveting Machine -Components

Applications of M618-NC Automatic Riveting Machine

- Automotive Manufacturing: Fastening body panels, chassis, brackets, and other components; suitable for various materials and fasteners.

- Electronics Assembly: Securing circuit boards, housings, connectors, and other electronic components with small, precise rivets.

- Hardware Production: Inserting rivets into locks, latches, hinges, doors, windows, and furniture for secure assembly.

- Aerospace Industry: High-precision riveting for aircraft structures, ensuring fasteners are correctly placed to maintain structural integrity.

- Metalworking and Fabrication: Riveting thick plates, beams, and structural components in metal fabrication and heavy machinery manufacturing.

- Shipbuilding: Securing metal plates and structural components in ships, ensuring strong and reliable riveting for safety and performance.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.