- 1.0What Is 5052 Aluminum Alloy?

- 2.05052 vs. Other Common Aluminum Alloys

- 3.0What Is 5052 Aluminum Used For?

- 4.0Specifications, Standards & Available Forms

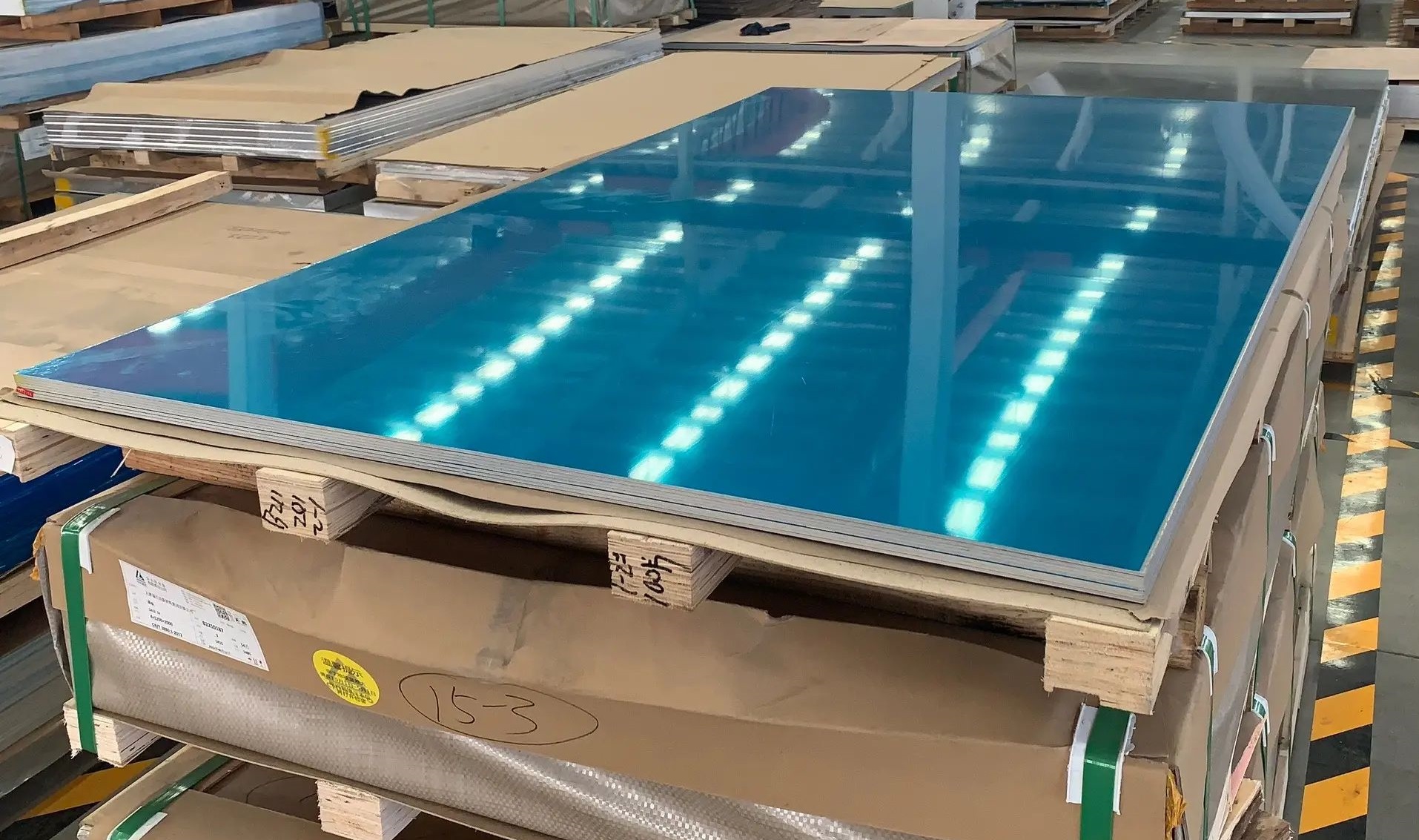

- 5.0How to Procure 5052 Aluminum

- 6.0How to Cut 5052 Aluminum (Including Aluminum Cutting Machines)

- 7.0FAQ: 5052 Aluminum Alloy

- 8.0Conclusion: Why 5052 Aluminum Remains a Top Industry Choice

When it comes to non-heat-treatable aluminum alloys with excellent corrosion resistance and superior formability, 5052 aluminum alloy stands out as one of the most versatile and widely used options in modern manufacturing. Thanks to its magnesium-rich chemical composition and work-hardening strengthening mechanism, 5052 delivers a balance of durability, weldability, and cost-effectiveness across diverse industries—from marine engineering to consumer electronics.

This comprehensive guide covers everything you need to know about 5052 aluminum: chemical composition, physical and mechanical properties, advantages, comparisons with other alloys, processing methods, applications, and purchasing tips.

1.0What Is 5052 Aluminum Alloy?

5052 aluminum is a non-heat-treatable, magnesium-based alloy in the 5xxx series. Instead of using heat treatment to improve strength, it relies on cold working (work hardening) to achieve higher mechanical performance.

Key characteristics include:

- Outstanding corrosion resistance (especially in seawater and chemical environments)

- High fatigue strength

- Excellent formability in the annealed state

- Good weldability without post-weld heat treatment

- Moderate machinability

- Compatibility with hard anodizing (matte gray finish)

Compared to popular wrought alloys such as 1100 or 3003, 5052 offers higher base strength and far better resistance to harsh environments.

What Is the Chemical Composition of 5052 Aluminum Alloy?

| Element | Composition Range | Element | Composition Range |

| Aluminum (Al) | Balance | Manganese (Mn) | ≤0.10 |

| Magnesium (Mg) | 2.2–2.8 | Zinc (Zn) | ≤0.10 |

| Chromium (Cr) | 0.15–0.35 | Titanium (Ti) | ≤0.05 (varies) |

| Silicon (Si) | ≤0.25 | Other Impurities | Each ≤0.05; Total ≤0.15 |

| Iron (Fe) | ≤0.40 | – | – |

| Copper (Cu) | ≤0.10 | – | – |

Exact composition depends on melt lot and specification. Always verify via the MTR (Mill Test Report).

What Physical Properties Make 5052 Aluminum a High-Performance Alloy?

| Property | Value |

| Density | 2.68 g/cm³ |

| Melting Range | 596–649°C |

| Elastic Modulus | 70 GPa |

| Shear Modulus | 26 GPa |

| Poisson’s Ratio | 0.33 |

| Specific Heat | 920 J/(kg·°C) |

| Thermal Conductivity | 151 W/(m·K) |

| Electrical Conductivity | 35% IACS |

What Are the Mechanical Properties of 5052 Aluminum Alloy?

| Temper | Tensile Strength (psi) | Yield Strength (psi) | Elongation (%) | Hardness (HB) |

| O (Annealed) | 28,000 | 13,000 | 22–30 | 47 |

| H32 | 33,000 | 28,000 | 12–18 | 60 |

| H34 | 38,000 | 31,000 | 10–14 | 68 |

| H36 | 40,000 | 35,000 | 8–10 | 73 |

| H38 | 42,000 | 37,000 | 7–8 | 77 |

What Are the Advantages of 5052 Aluminum Alloy?

1.1Superior Corrosion Resistance

Ideal for:

- Saltwater / marine environments

- Chemical processing

- Industrial atmospheres

Magnesium and chromium enhance pitting and general corrosion resistance, making 5052 a true marine-grade aluminum.

1.2Excellent Strength-to-Weight Ratio

Compared to 1100 and 3003, 5052 delivers higher tensile strength while remaining lightweight—perfect for energy-efficient and structural applications.

1.3Outstanding Formability

In O temper, 5052 handles:

- Deep drawing

- Bending

- Stretch forming

- Complex shapes

This makes it a top choice for consumer products and industrial housings.

1.4Reliable Weldability

- Compatible with MIG/TIG welding

- No post-weld heat treatment needed

- Welded areas retain strong corrosion resistance

1.5High Fatigue Strength

Ideal for parts subjected to vibration or repeated stress cycles.

1.6Fully Recyclable

Eco-friendly with minimal performance loss after recycling.

1.7Versatile Surface Finishing

Supports:

- Hard anodizing (matte gray)

- Powder coating

- Painting

- Electrocoating

2.05052 vs. Other Common Aluminum Alloys

| Alloy | Key Features | Typical Uses |

| 5052 | Non-heat-treatable, great corrosion resistance, very formable | Marine equipment, fuel tanks, panels |

| 6061 | Heat-treatable, higher strength, good machining | Frames, aerospace fittings |

| 7075 | Extremely strong, lower corrosion resistance | High-performance components |

| 3003 | Very formable, low cost, lower strength | Household goods, light panels |

How to Process and Manufacture with 5052 Aluminum Alloy

2.1Forming

- O temper: best for deep drawing

- H32/H34: balance between strength and formability

- H38: hardest, more springback

2.2Welding

- MIG and TIG recommended

- No preheating required

- Avoid high-temperature post-weld treatments

2.3Machining

- Moderate machinability

- Use sharp carbide tools

- Apply lubrication to minimize built-up edge

2.4Surface Finishing

- Hard anodized surfaces are uniform and wear-resistant

- Finish is typically matte, not mirror-bright

2.5Precautions

- Avoid long exposure to 345–400°C

- Anneal at 300–400°C to restore ductility

- Avoid strong acids/alkalis for long durations

3.0What Is 5052 Aluminum Used For?

3.1Marine Industry

- Ship hulls

- Deck plates

- Marine hardware

- Fuel/water tanks

3.2Transportation

- Aerospace fuel lines

- Automotive/truck fuel tanks

- Body panels

- Road signs

3.3Architecture

- Curtain walls

- Roof and facade panels

- Handrails

- Rainwater systems

3.4Consumer & Electronics

- Housing panels

- Cookware

- Lighting fixtures

- Electronic enclosures

3.5Industrial

- Pressure vessels

- Food processing equipment

- Chemical storage tanks

- Heat exchangers

4.0Specifications, Standards & Available Forms

4.1Common Forms

- Sheet & plate (0.2–50 mm thickness)

- Coil

- Patterned plate (diamond tread)

- Tube/Pipe (welded or seamless)

4.2Standards

- ASTM B209

- AMS 4016

- QQ-A-250/8

- UNS A95052

- ISO AlMg2.5

5.0How to Procure 5052 Aluminum

When purchasing, consider:

- Required temper (O, H32, H34, etc.)

- Thickness & width

- Surface finish

- Processing needs (welding, forming, anodizing)

Typical suppliers include major metal distributors offering:

- Cutting services

- Bulk orders

- Same-day/next-day delivery (region-dependent)

6.0How to Cut 5052 Aluminum (Including Aluminum Cutting Machines)

Because 5052 aluminum is strong yet ductile, it can be cut using multiple methods. The choice depends on thickness, precision requirements, and production volume.

6.1Aluminum Cutting Machine (Most Recommended)

An aluminum cutting machine—typically equipped with a high-speed spindle and a carbide-tipped blade designed specifically for aluminum—is the best and most efficient tool for cutting 5052 sheet, plate, tubes, and extrusions.

Advantages:

- Clean, smooth edges with minimal burrs

- Fast cutting speed

- Very low risk of deformation

- Ideal for medium to high production volume

- Works well on both thin and thick 5052 plates

Where it excels:

- Fabrication workshops

- Industrial production lines

- Automotive and aerospace cutting operations

- Bulk cutting of aluminum bars, plates, and profiles

For businesses processing 5052 regularly, a dedicated aluminum cutting machine provides the highest precision and reliability.

6.2Laser Cutting (Fiber Laser)

Suitable for thin to medium-thickness 5052 sheets (0.5–8 mm).

- Pros: high precision, clean edges, complex shapes

- Cons: aluminum’s reflectivity requires high-power machines and skilled operators

6.3Mechanical Cutting (Shears, Band Saw, Circular Saw)

Good for general-purpose fabrication:

- Shears: fast for thin sheet; may create slight edge distortion

- Band saw: suitable for thick plate or bar stock

- Circular saw: clean edge when used with aluminum-grade blades

6.4Waterjet Cutting

Excellent for thick 5052 or heat-sensitive applications.

Advantages:

- No heat-affected zone

- No microstructural change

- High precision

6.5Tips for Cutting 5052 Aluminum

- Use proper lubrication to reduce heat and burrs

- Use carbide blades designed for non-ferrous metals

- Control feed speed to avoid warping

- Wear protective eyewear and gloves when cutting

7.0FAQ: 5052 Aluminum Alloy

7.1Is 5052 aluminum easy to machine?

It has moderate machinability. Sharp carbide tools and proper lubrication are recommended to prevent built-up edge.

7.2Can 5052 aluminum be anodized?

Yes. It performs well in hard anodizing but produces a matte gray finish rather than a bright decorative surface.

7.3Is 5052 better than 6061?

It depends:

- 5052 → better for forming and corrosion resistance

- 6061 → stronger and better for machining or structural parts

7.4What is the best way to cut 5052 aluminum?

A dedicated aluminum cutting machine with carbide-tipped blades is ideal for clean, precise, and fast cuts—especially for high-volume production.

7.5Is 5052 safe for food-contact applications?

Yes, many grades meet FDA/food safety standards, but always verify with the Mill Test Report (MTR).

7.6What temper should I choose for forming?

- O temper: best formability (deep drawing)

- H32/H34: balanced strength and formability

- H38: maximum hardness, minimal formability

8.0Conclusion: Why 5052 Aluminum Remains a Top Industry Choice

5052 aluminum is one of the most balanced and versatile non-heat-treatable alloys available today. Combining:

- High corrosion resistance

- Superior formability

- Excellent fatigue performance

- Good weldability

- Lightweight nature

…it suits demanding applications in marine, transportation, electronics, architecture, and industrial equipment.

If you need a durable, formable, corrosion-resistant aluminum alloy that performs in both harsh and everyday environments, 5052 is a dependable and cost-effective choice.

Reference

https://www.mcmaster.com/products/aluminum-sheets/material~aluminum-2/material~5052-aluminum/

https://www.hydro.com/us/us/aluminum/products/extruded-profiles/north-america-resources/extruded-aluminum-products/aluminum-extrusion-alloys/5052-aluminum/

https://www.kloecknermetals.com/blog/why-5052-aluminum-is-so-popular-with-our-customers/

https://www.alro.com/divsteel/metals_gridpt.aspx?gp=0146