- 1.0What Is 3D Laser Tube Cutting?

- 2.0Application Examples of 3D Laser Tube Cutting Technology

- 3.0What Is a 3D Tube Laser Cutting Machine?

- 4.0Key Components of a 3D Laser Tube Cutting System

- 5.0How to Choose the Right 3D Laser Tube Cutting Machine

- 6.0Key Differences Between 2D and 3D Laser Cutting

- 7.0Core Advantages of 3D Laser Tube Cutting

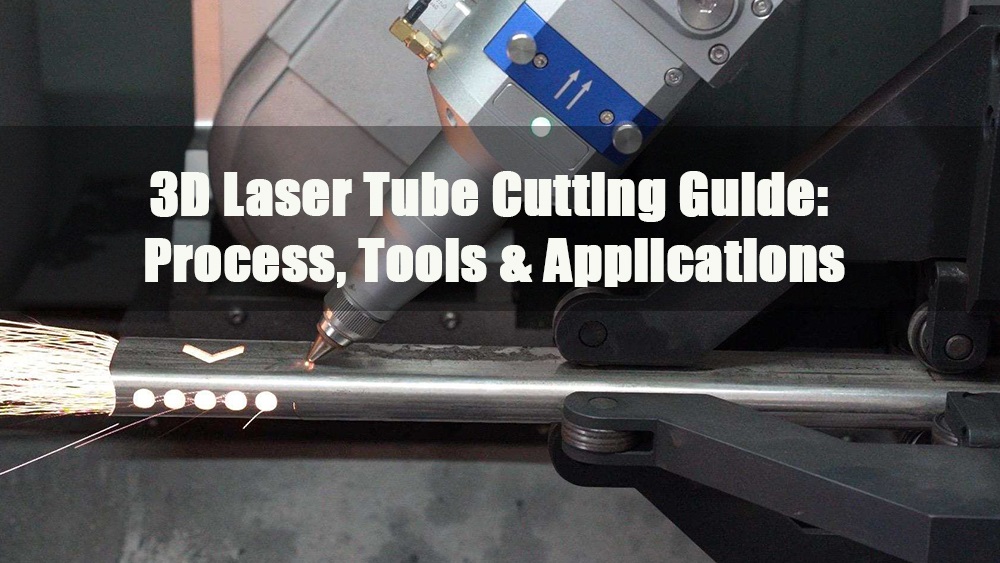

3D Laser Tube Cutting Guide: Process, Tools & Applications

In 1964, the world’s first industrial laser was introduced, delivering a modest output of just 1 milliwatt (mW). Within only three years, by 1967, laser power had surpassed 1,000 watts—enough to cut through 1 mm thick steel—representing a million-fold leap in energy output. This breakthrough marked the beginning of the laser processing era.

Driven by the demands of modern manufacturing for high precision, efficiency, and flexibility, traditional tube cutting methods have increasingly struggled to meet diversified production requirements. In response, 3D laser tube cutting technology emerged—combining high-power lasers, high-speed multi-axis CNC systems, and intelligent software control—to become a key innovation in advanced tube processing.

Compared to conventional 2D laser cutting, 3D technology offers significant benefits:

- Complex Geometry Cutting: Enables accurate cutting of tubes with spatially complex or angled features.

- Enhanced Cut Quality: Delivers cleaner edges, reduced burrs, and minimal post-processing requirements.

- Increased Structural Flexibility: Supports innovative joint designs and optimized part geometries for structural performance.

- Improved Production Efficiency: Reduces the need for secondary operations such as deburring or welding preparation.

Design and Manufacturing Freedom: This technology opens new possibilities for processing structural components, non-standard tube profiles, and automotive parts, offering unprecedented freedom in both design and manufacturing.

Technology Demands: Despite its advantages, 3D laser tube cutting comes with higher technical requirements. Achieving consistent, high-quality results depends on an integrated system-level approach—encompassing mechanical design, synchronized CNC control, and advanced toolpath optimization algorithms.

1.0What Is 3D Laser Tube Cutting?

3D laser tube cutting is an advanced manufacturing process that uses a high-energy laser beam, guided by a multi-axis motion system, to perform precise cuts and beveling operations on metal tubes at any spatial angle. Unlike traditional 2D cutting, it goes beyond flat end cuts to enable angled cuts, irregular profiles, and complex spatial contours.You Might Also Like: Tube Laser Cutting: The Complete Guide

Multi-Axis Capability and Material Flexibility:

Equipped with a rotating and tilting laser cutting head, 3D laser systems can process round tubes, square and rectangular tubes, C-channels, angle irons, elliptical profiles, and open-section shapes. The cutting head can tilt across multiple axes, offering up to 45° cutting angles. This makes it ideal for countersunk holes, chamfering, and beveled edges, particularly beneficial in applications requiring welded joints or filler-free weld preparation.

Integrated Multi-Tasking:

A 3D laser system can perform cutting, beveling, and chamfering in a single operation, reducing manual intervention and production time. It supports both prototyping and high-volume production, adapting flexibly to various manufacturing scenarios.

Key Control Requirements for 3D Tube Processing:

Unlike flat sheet processing, tube cutting requires the laser beam to move dynamically around a 3D structure. This necessitates precise control of several critical parameters:

- Nozzle Distance and Focal Position: Must adjust dynamically based on tube radius and cut geometry

- Laser Power and Cutting Speed: Require real-time adaptation to variations in wall thickness

- Focus Height Adjustment: Dynamic focusing improves cut quality and efficiency, minimizing thermal damage and material waste

Challenges of Angled Cutting and Compensation Measures:

Since laser beams have a conical profile, the kerf width changes with the cutting angle, potentially affecting dimensional accuracy and weld fit-up. To compensate:

- Kerf Compensation: The system must adjust for kerf width variation to maintain correct part lengths and joint precision

- Focus and Gas Flow Control:Modifying focus position and assist gas angle helps prevent turbulence and gas loss—especially critical at 45° tilts—to ensure stable and efficient cutting

Real-Time Compensation for Tube Irregularities:

Tubes may exhibit initial bending, lateral deviation, or deformation due to cantilevered positioning. Advanced 3D laser cutting machines equipped with integrated measurement and support systems can detect and compensate for these issues in real time—reducing tolerance errors and material waste.

2.0Application Examples of 3D Laser Tube Cutting Technology

3D laser tube cutting is widely applied in modern manufacturing for high-precision and high-efficiency tube processing. It is especially well-suited for sectors such as steel structures, aerospace, and other industries requiring complex fabrication. Below are typical application scenarios that highlight the advantages and practical use of this advanced technology:

- Automatic Feeding and Tube Loading:

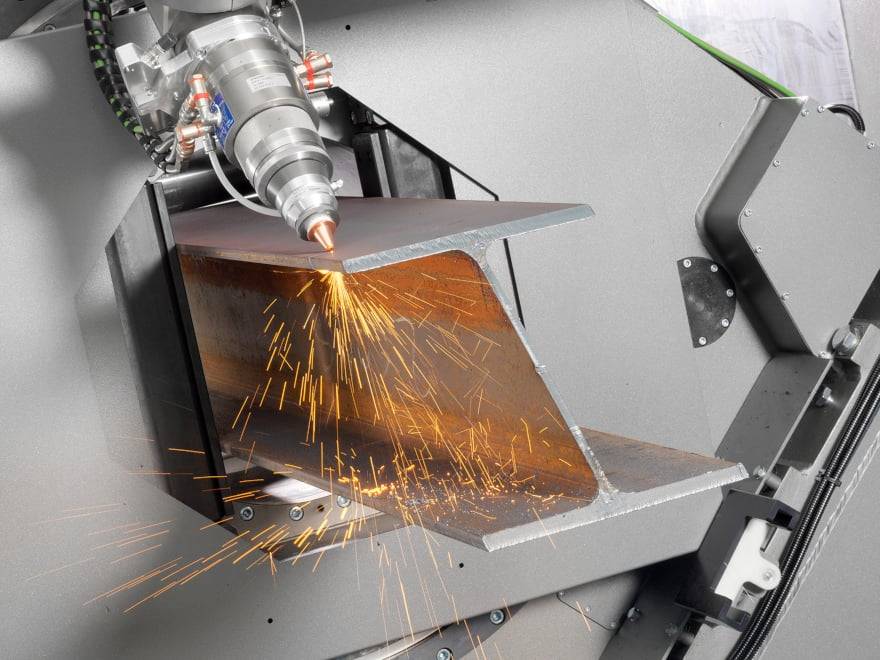

Automated bundle loaders efficiently handle heavy tubes, significantly reducing setup time and improving operator safety. In high-volume production, automation ensures fast and stable tube positioning at the cutting station, dramatically increasing throughput and reducing labor requirements. - Heavy-Duty Tube Cutting and Beveling:

Capable of performing precise, zero-waste cuts and bevels on H-beams, U-channels, and L-profiles. The system is equipped with a full-stroke three-chuck support mechanism to ensure secure clamping throughout the process. It is widely used in structural steel, tower manufacturing, and bridge construction—meeting the demand for high-precision fabrication. - High-Precision Cutting with Intelligent Nesting:

With ALEKVS intelligent nesting software, cutting paths are automatically optimized to minimize material waste. The software supports path sequencing for both square and round tubes, generating toolpaths based on surface order or spacing to enable efficient and consistent cutting. - Zero-Waste Cutting Technology:

For heavy-duty applications, the intelligent three-chuck zero-waste cutting system eliminates material loss. By enabling synchronized motion among multiple chucks, the system ensures full-length and accurate cutting of long tubes without generating scrap, effectively lowering production costs. - Dynamic Support for Heavy Tubes:

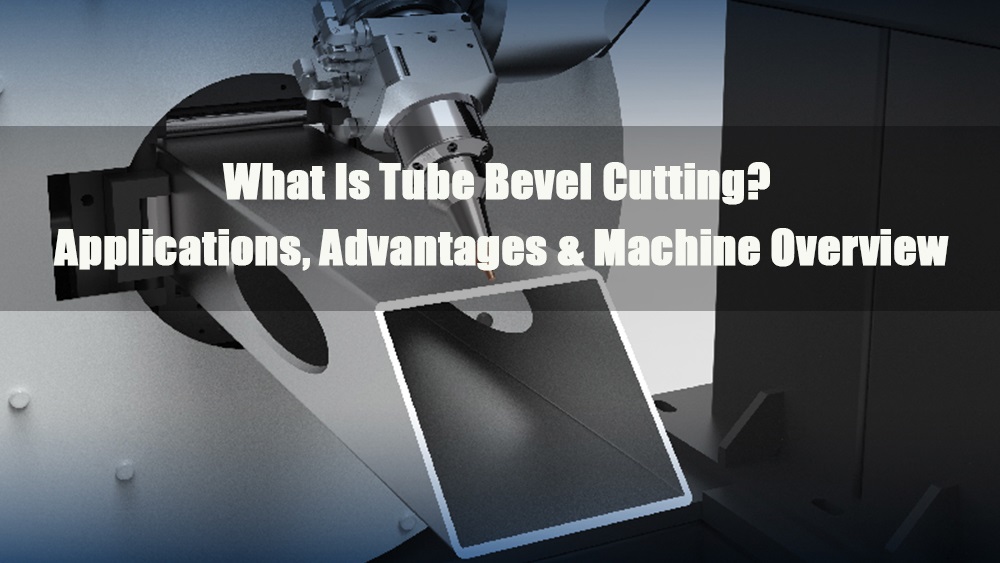

A full-stroke servo-driven follow-up support system adjusts in real time to maintain vertical positioning of the tube during cutting. This prevents sagging or oscillation and ensures cutting stability and accuracy across the entire workpiece—particularly important for long or heavy tubes. - Multi-Function Cutting Capabilities:

The 3D laser head supports advanced functions such as 45° bevel cutting, improving weld strength and uniformity. It also enables precision creation of Y-branch holes for multi-directional tube connections, meeting the needs of complex structural components. - Processing of Shaped Tubes and Complex Structures:

3D laser cutting allows for spatial contour following, making it possible to process irregularly bent tubes and complex 3D structural parts. This capability is ideal for custom, high-precision applications such as assembly slots or alignment holes in furniture frameworks and industrial structures.

3.0What Is a 3D Tube Laser Cutting Machine?

A 3D tube laser cutting machine is a high-precision CNC system designed for cutting and beveling metal tubes at various spatial angles. Utilizing a laser beam as the energy source and a multi-axis motion control system, it enables accurate cutting on complex surfaces and at non-vertical angles. It is a key tool in advanced manufacturing and intelligent fabrication.

Core Functions and Applications:

A 3D tube laser cutting machine features multi-axis coordination—typically 5-axis or 6-axis—to process a wide range of metal tube profiles, including round, square, rectangular, and elliptical tubes. It is capable of performing angular cuts, spatial bevels, holes, and other complex geometries with high precision.

Working Principle:

The fiber laser generates a high-energy beam that is focused by the cutting head onto the tube surface, melting the material locally to achieve cutting.

The 3D cutting head is capable of both rotation and tilt, operating in coordination with X, Y, Z, and rotary axes to precisely control the beam path and perform complex 3D cutting tasks.

The system supports cutting at various inclined angles—such as 45° or 60°—to prepare weld-ready bevels and complex contours.

Main Components:

- Laser Source:Typically a fiber laser with power ranging from 1kW to 6kW

- 3D Cutting Head:Allows both tilting and rotational movement for multi-angle operations

- CNC Control System:Enables multi-axis coordination, supports CAM file import for efficient programming

- Automatic Clamping and Rotary Feeding System:Ensures accurate tube positioning and feeding

- Tail Stock and Intelligent Nesting System (Optional):Optimizes material usage and reduces waste

Example Cutting Capabilities:

- Tube-End Angular Cuts / Beveling:Provides precise angles for welding preparation

- Hole Cutting at Arbitrary Angles:Suitable for complex hole placements across tube surfaces

- Interlocking Slots and Positioning Holes:Enables precision fitting and assembly alignment

4.0Key Components of a 3D Laser Tube Cutting System

- Fiber Laser Source:

Delivers high energy density with low maintenance requirements and excellent compatibility with reflective materials. Fiber lasers provide a stable beam output for precision cutting while minimizing operational costs. - 3D Laser Cutting Head:

Equipped with integrated rotation, tilt mechanisms, and auto-focusing optics, the cutting head enables precise cutting at any spatial angle. It supports a wide range of applications—from tube-end cuts to complex 3D profiles—enhancing process flexibility. - Multi-Axis Motion Control System:

Supports 5-axis or 6-axis synchronized motion (X/Y/Z + rotation + tilt), enabling simultaneous multi-dimensional cutting. This is essential for handling complex tube geometries and improving production throughput. - Intelligent Clamping and Follow-Up Support System:

Automatically identifies the tube type and ensures precise clamping and alignment. The servo-driven support system adjusts in real time during cutting to prevent deformation or vibration, ensuring stable and accurate results. - Integrated CAM Software:

Allows for direct CAD file import, toolpath planning, and intelligent simulation. The CAM system automatically optimizes cutting parameters based on geometry, reducing material waste and cycle times. - Automated Nesting and Toolpath Optimization:

Built-in nesting functionality arranges cutting layouts based on tube length and profile dimensions, maximizing material utilization and improving operational efficiency. - High-Speed Precision Servo Drive System:

Advanced servo motors and drives enable fast cutting and highly accurate positioning. This ensures consistent results even when processing complex shapes and varying wall thicknesses. - Laser Power Control System:

Automatically adjusts laser power based on material type and thickness to achieve an optimal cutting balance—avoiding over- or undercutting, and enhancing both cut quality and material efficiency. - Assist Gas Cutting System:

Precisely regulates gas flow to optimize the heat-affected zone during cutting. This minimizes burrs and edge deformation while increasing cutting speed and process reliability. - Integrated Remote Monitoring and Maintenance:

The system includes remote diagnostics to monitor machine status in real time. It can detect potential faults in advance and issue alerts, reducing downtime and improving maintenance scheduling.

5.0How to Choose the Right 3D Laser Tube Cutting Machine

When selecting a 3D laser tube cutting system, beyond basic technical specifications, it is essential to evaluate the machine based on actual production requirements and shop-floor conditions. The following factors should be considered:

- Supported Tube Types and Size Range:

Ensure that the machine can handle the specific dimensions and profiles required for your applications. Key parameters include:- Round Tube Diameter Range:Different machines support different diameter ranges—make sure they align with your processing needs.

- Wall Thickness Limit:For thick-walled tubes (greater than 5 mm), higher laser power is crucial to ensure efficient cutting.

- Compatibility with Non-Standard Profiles:If processing square, rectangular, or other special-shaped tubes is required, confirm the machine’s capability to support these profiles.

- Availability of Automated Loading and Unloading Systems:

Automation significantly improves productivity and reduces manual labor, especially in high-volume production. An automated material handling system enables seamless tube feeding across batches, minimizing downtime and maximizing output efficiency. - Requirement for Bevel Cutting Capability:

If your application involves welded assemblies, prioritize machines equipped with bevel cutting functionality. Beveling allows angled cuts on tube ends to enhance weld strength, accuracy, and consistency—directly impacting the final product quality. - Laser Power Matching:

Laser power should be matched to the material type and wall thickness. For tubes thicker than 5 mm, a laser power output above 3 kW is recommended to maintain cut quality and speed. Higher power allows deeper and faster cuts, making it suitable for processing heavy-walled materials. - Software Usability and Expandability:

The integrated control software directly affects ease of operation and cutting accuracy. Consider the following:- Ease of Use:Evaluate whether the software interface is user-friendly, supports CAD file import, and allows efficient toolpath planning.

- Expandability:Assess whether the system can support future upgrades, new features, and integration with other machines or production systems.

6.0Key Differences Between 2D and 3D Laser Cutting

| Comparison Criteria | 2D Laser Cutting | 3D Laser Cutting |

| Processing Dimensions | Limited to flat materials; operates in two dimensions | Capable of cutting in three-dimensional space; supports complex shapes and curves |

| Applicable Materials | Primarily flat sheet metal (e.g., steel sheets, thin plates) | Suitable for tubes, profiles, and irregular-shaped materials |

| Cutting Angles & Accuracy | Supports only perpendicular cuts on a 2D plane; limited angular flexibility | Enables angled and non-vertical cuts; up to 45° bevels for weld preparation |

| Cutting Head & Motion System | Uses a basic XY-axis control system; relatively simple mechanics | Employs multi-axis systems (5 or 6 axes); laser head supports tilt and rotation |

| Processing Complexity | Ideal for simple 2D geometries; conventional applications | Suited for complex geometries; ideal for angular and 3D contour tube processing |

| Efficiency & Adaptability | High throughput for flat parts; limited in application range | Lower throughput but better suited for custom, high-precision jobs |

| Industry Applications | Sheet metal, automotive, home appliances, electronics | Automotive, aerospace, machinery—especially for structural tube cutting |

7.0Core Advantages of 3D Laser Tube Cutting

- Speed: Laser cutting operates significantly faster than traditional mechanical cutting, particularly for intricate geometries and multi-angle operations.

- Quality: 3D laser cutting delivers clean edges with minimal burr formation. The heat-affected zone (HAZ) is narrow, reducing material deformation and ensuring high-quality finished parts.

- Versatility: One system can process a wide range of materials—such as steel, stainless steel, and aluminum—and supports various profiles including round, square, rectangular tubes, angle iron, and I-beams.

- Precision: Offers exceptional cutting accuracy, with tolerances as tight as +/- 0.005 inches (0.127 mm). Post-processing is often unnecessary, minimizing material waste and reducing production costs.

- Safety: Laser cutting is a contactless and enclosed process. The beam is confined within a light-tight enclosure, minimizing risks of operator injury and machine damage.

- Non-Contact Operation: Since there are no physical cutting tools, mechanical wear and friction are eliminated. This results in less machine maintenance and longer equipment lifespan.

- Low Power Consumption: Laser cutting systems are energy-efficient, even in high-volume production environments. They maintain high throughput while minimizing overall energy costs.

References

https://blog.blmgroup.com/advantages-and-limits-of-tube-3d-laser-cutting