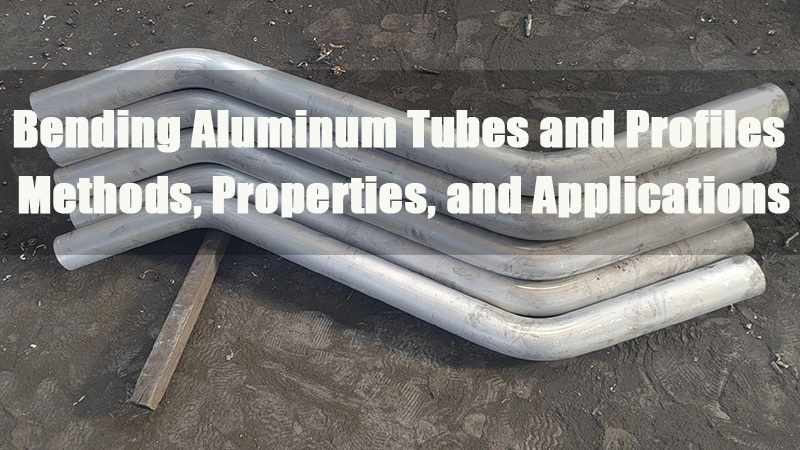

Typical Applications

- Automotive: Exhaust systems, chassis pipes, HVAC pipelines

- Construction & Heavy Equipment: Hydraulic pipes, structural frames

- Furniture & Fitness Equipment: Bicycle frames, treadmill frames, metal supports

- Aerospace, marine, sanitary ware, steel structures, and other industries requiring precision pipe bending

Key Technical Advantages

High-Precision Transmission

- Precision RV reducer with backlash ≤ 3 arc-min

- Ground helical gear transmission with backlash compensation

- Improved bending angle control and arc consistency

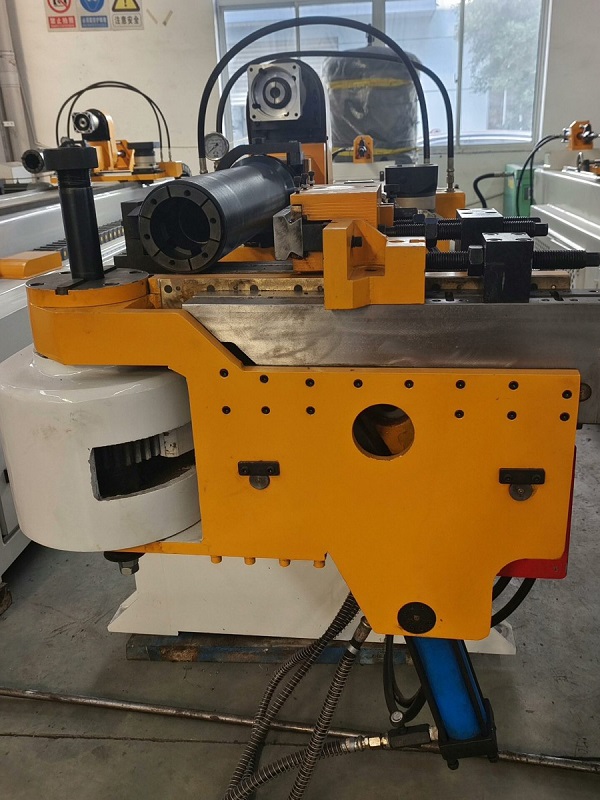

Heavy-Duty, High-Rigidity Structure

- Large-module rack and pinion transmission

- High-specification linear guideways

- Ensures long-term accuracy and structural stability under continuous operation

Structural & Maintenance Design

- High-rigidity machine frame designed based on dynamic mechanics principles

- Streamlined bending arm and bending head maximize bending space and reduce interference

- Automatic lubrication system for the bending head and mandrel

- Separate oil tank with a filtration system for easy maintenance

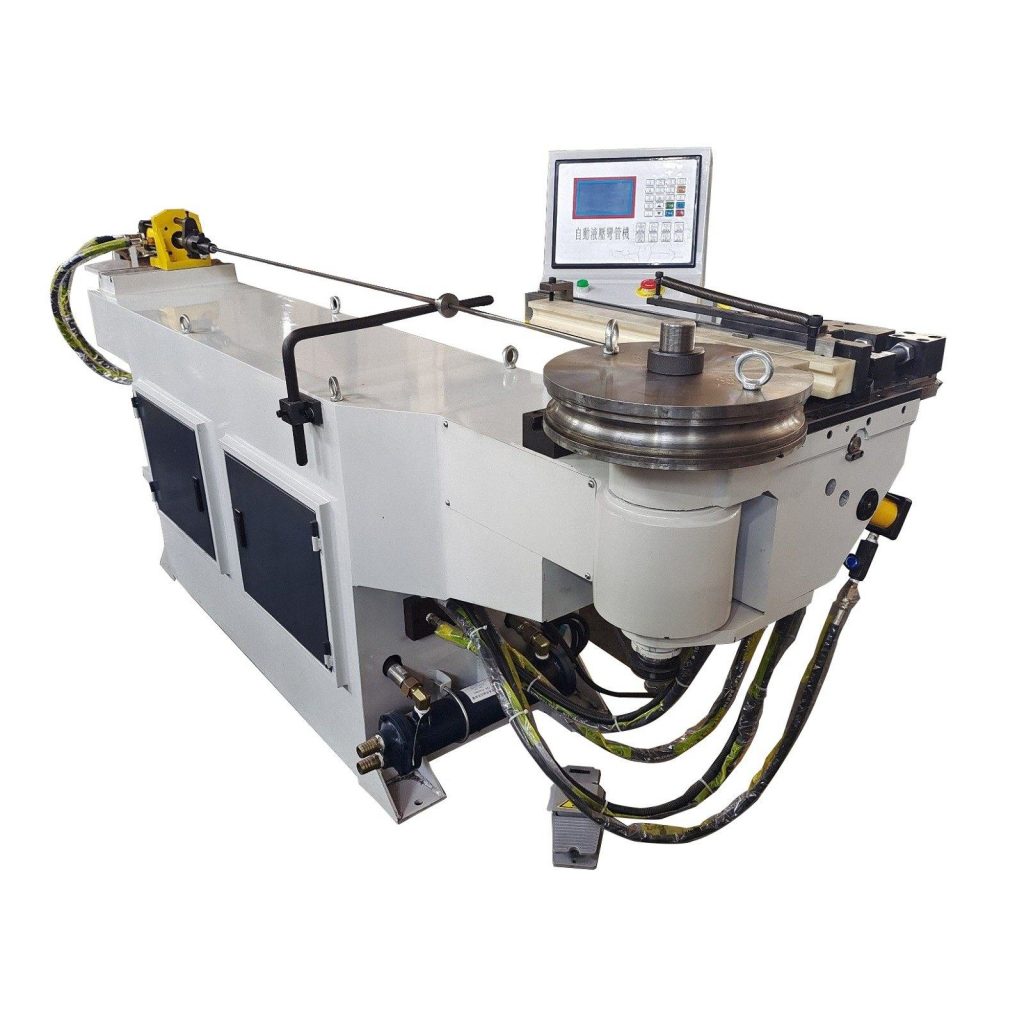

Drive System & Operating Principle

The AEK-3D 89CNC adopts a 3D CNC control system to precisely coordinate multi-axis motion and complete complex spatial bending operations.

- Feeding (Y-axis): Servo motor driven

- Pipe rotation (B-axis): Servo motor driven

- Bending (C-axis): Hydraulic drive with encoder closed-loop control

- Clamping & auxiliary actions: Pneumatic system (main clamp, guide clamp, pressure die, mandrel, etc.)

All movements are synchronized through CNC programs, ensuring high-speed response while maintaining bending stability and forming accuracy.

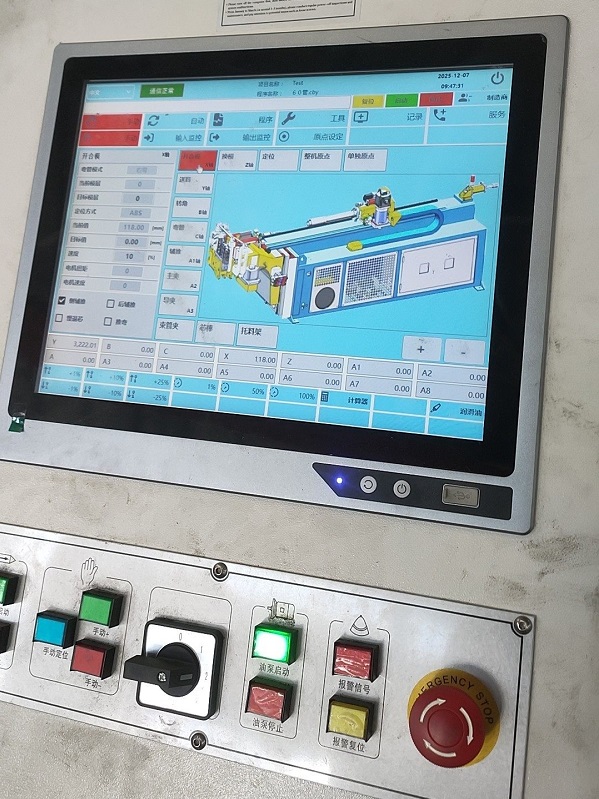

Automation & Intelligent Functions

- Fully automatic CNC pipe-bending operation

- Self-diagnostic system with real-time fault indication

- Touch-screen HMI for intuitive operation

- Independent cooling systems for the electrical cabinet and hydraulic unit, suitable for long-term continuous production

Tooling System & Expansion Options

- Standard tooling includes:

- Clamp die, pressure die, bend die, wiper die, mandrel

- Tooling can be customized according to pipe diameter and bending requirements

- Quick die-change design reduces setup time

- Re-clamping function supports extra-long pipe processing

- Optional functions:

- Hole punching, pipe cutting, multi-radius bending, roll bending, and fast mandrel extraction for thin-wall pipes.

Thin-Wall & Small-Radius Bending Capability

- High-power feeding servo motor with rear boost assist

- Stable forming of thin-wall stainless steel pipes

- Capable of 1D small-radius bending

- Optional servo side-assist push system reduces wall thinning and deformation

Advanced CNC Control System

- Supports manual operation editing into automatic machining programs

- Multiple pipe programs can be stored for batch and mixed production

- High-end PLC with absolute servo motors

- EtherCAT communication for full closed-loop control and minimized accuracy loss

- Optional industrial PC (IPC) system supporting:

- 3D pipe drawing import and programming

- 3D forming preview

- Dynamic bending simulation

- Remote diagnostics and technical support

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.