- 1.020 Metal Table Leg Styles

- 1.1Straight Legs

- 1.2Tapered Legs

- 1.3Angled Legs

- 1.4A-Shaped Legs

- 1.5C-Shaped Legs

- 1.6X-Shaped Legs

- 1.7T-Shaped Legs

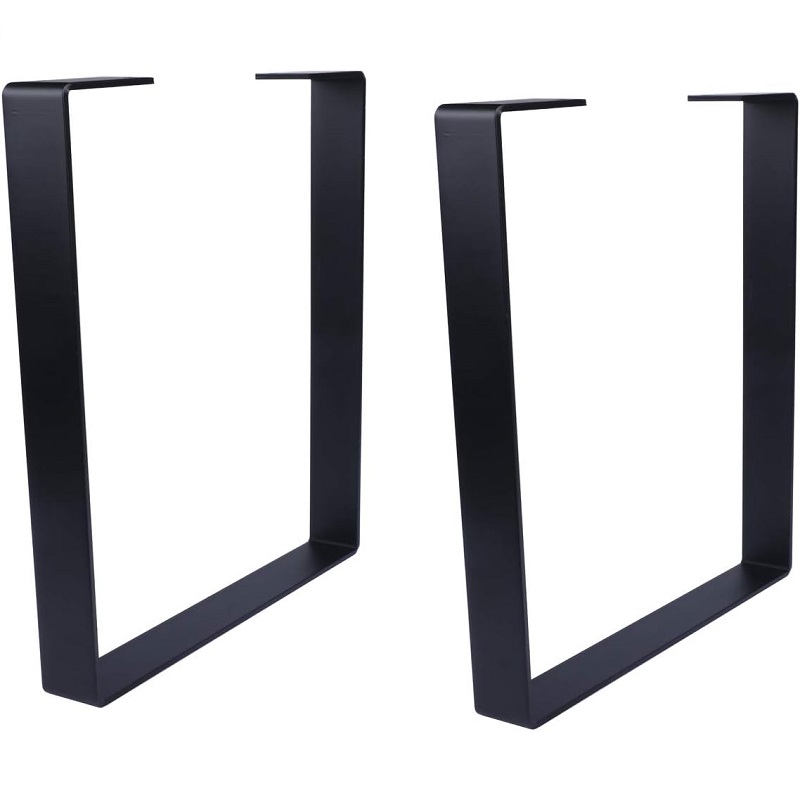

- 1.8U-Shaped Legs

- 1.9V-Shaped Legs

- 1.10H-Shaped Legs

- 1.11L-Shaped Legs

- 1.12Y-Shaped Legs

- 1.13Z-Shaped Legs

- 1.14Trapezoid Legs

- 1.15Hairpin Legs

- 1.16Arch Legs

- 1.17Bridge Legs

- 1.18Frame Legs

- 1.19Tripod Legs

- 1.20Pedestal Leg / Center Column

- 2.0Common Metal Materials for Table Legs

- 3.0Is Stainless Steel Suitable for Table Legs?

- 4.0How to Choose the Best Metal Table Legs for Your Project

When discussing tables, we often focus on the tabletop but overlook the importance of table legs in stability and style. Table legs vary widely in types, materials, and designs, balancing functionality and aesthetics.

In metal furniture, leg designs not only provide structural support but also define the piece’s overall look, from minimalist to industrial and vintage styles, each with distinct construction and manufacturing methods.

This article covers 20 common metal table leg styles—from straight and tapered to X-shaped and bridge legs—along with their typical uses, material choices, manufacturing steps, and key equipment.

1.020 Metal Table Leg Styles

1.1Straight Legs

- Structure: Made from round or square tubes, vertically mounted with no taper. This is the simplest and most universal design, often paired with screw-in bases, adjustable feet, or plastic end caps for added functionality.

- Applications: Office desks, storage cabinets, study tables, TV stands, and industrial workbenches.

Production Method:

- Material: C arbon steel, stainless steel, or aluminum alloy tubing

- Process: Tube cutting → Deburring ends → Welding base plate → Powder coating or electroplating

- Common Equipment: Tube cutter, welding workstation, coating line

1.2Tapered Legs

- Structure: Tapered from top to bottom, often in conical or pyramidal shapes. This design offers a lighter, more elegant look while maintaining strength. Tapering is achieved through swaging, tapered castings, or press-formed pieces, sometimes reinforced internally.

- Tapered Pedestal: A central column narrows the width of the tabletop to the base.

- Dual-Tapered Legs: Both upper and lower segments are tapered, common in vintage-style furniture.

- Applications: Dining chairs, vanities, side tables, modern desks, and high-end display units.

- Production Method:

- Material: Preformed tapered steel, stainless steel, or aluminum tubes, or round tubes shaped by swaging

- Process Option 1: Cut tapered tube to length → Deburr → Weld base/nut → Surface finishing

- Process Option 2: Swage round tube → Heat treatment → Weld or bolt assembly → Paint or plate

- Common Equipment: Tube swaging machine, CNC lathe (for machined tapers), automated welding station, polishing and coating systems

1.3Angled Legs

- Structure: Legs slant outward or inward, adding a dynamic aesthetic and enhancing load distribution. Commonly paired with tapered or flat tubes for a sleek finish. Popular in Nordic or contemporary designs.

- Applications: Dining chairs, coffee tables, desks, and lounge seating.

- Production Method:

- Material: Round, oval, or custom-tapered tubes

- Process: Angle cutting → Deburring → Precision welding or screw assembly → Surface treatment

- Common Equipment: Angle saws, jigs for angled fixtures, robotic welders, powder coating systems

1.4A-Shaped Legs

- Structure: Two slanted tubes form an inverted “V” and are joined at the bottom with a horizontal crossbar, creating an “A” shape. Offers strong load-bearing and geometric stability.

- Applications: Dining tables, workbenches, desks, and sturdy chairs.

- Production Method:

- Material: Square or round tubing

- Process: Precision miter cutting → Top joint welding → Bottom beam connection → Powder coating or plating

- Common Equipment: Miter saw, welding jigs, electrostatic spraying equipment

1.5C-Shaped Legs

- Structure: Formed by side-bending metal tubing into a “C” shape, with one side open to slide under a sofa or bed. A cantilever-style design that balances function with space efficiency.

- Applications: Sofa tables, bedside trays, mobile coffee tables, and laptop stands.

- Production Method:

- Material: Stainless steel or carbon steel square tubing

- Process:Tube bending into “C” shape → Base plate welding → Polishing → Coating or plating

- Common Equipment: Tube bender, welding jigs, polishing and surface finishing machines

1.6X-Shaped Legs

- Structure: Two or more tubes intersect to form an “X”, providing excellent support and a distinctive look. Often includes a central crossbar for reinforcement.

- Applications: Benches, TV stands, coffee tables, and office desks.

- Production Method:

- Material: Flat or square tubing in carbon steel or stainless steel

- Process:Tube cutting → Fixture positioning → Angle welding → Grinding → Painting or plating

- Common Equipment: Tube shears, welding table, angle jigs, finishing systems

1.7T-Shaped Legs

- Structure: A vertical tube joined to a horizontal beam to form a “T”. Ideal for minimalist, single-leg support in compact or central structures.

- Applications: Side tables, small round tables, reception desks, and display stands.

- Production Method:

- Material: Stainless steel round or square tubing

- Process: Tube cutting → T-joint welding → Polishing or painting → Base flange installation

- Common Equipment: Tube cutter, T-joint jig, welding platform, polishing machine

1.8U-Shaped Legs

- Structure: Formed by bending metal tubing into a “U” shape, offering high integrity and durability. Both ends are typically screwed into the tabletop or frame, creating a clean, modern look. An inverted-U design is also common for long tables.

- Applications: Conference tables, side tables, office desks, storage units.

- Production Method:

- Material: Stainless steel or carbon steel, round or square tubing

- Process: Tube bending → End plate welding → Surface treatment (brushed, electroplated, or painted)

- Common Equipment: Tube bender, end-face welding fixture, grinding tools, powder coating system

1.9V-Shaped Legs

- Structure: Two tubes arranged in a “V” configuration, or a single shaped tube bent into a V. Offers bold aesthetics and stability, typically fixed to the underside of the tabletop with a central bracket.

- Applications: Accent chairs, single chairs, side tables, and small dining tables.

- Production Method:

- Material: Oval tubes, custom-shaped or tapered tubing

- Process: Angle cutting or bending → Welding → Surface finishing or plating

- Common Equipment: Miter saw, bending machine, welding jig, finishing system

1.10H-Shaped Legs

- Structure: Two vertical legs connected by a horizontal beam, forming an “H” structure. Enhances lateral rigidity and is ideal for heavy-duty furniture designs.

- Applications: Long dining tables, industrial workbenches, lab tables.

- Production Method:

- Material: Square tubing or steel plate components

- Process: Tube cutting → Welding into “H” shape → Surface treatment

- Common Equipment: Welding jigs, bending tools, spray coating line

1.11L-Shaped Legs

- Structure: Created by bending metal tubing at a right angle to form an “L” shape. Adds visual character and space efficiency, often used for wall-side setups or custom builds.

- Applications: Wall-mounted desks, display tables, compact workstations, functional furniture.

- Production Method:

- Material: Square or rectangular tubing

- Process: Precision bending → Welding support ribs or brackets → Powder coating or brushed finish

- Common Equipment: CNC bending machine, welding platform, coating or polishing equipment

1.12Y-Shaped Legs

- Structure: Starts as a single upper column that splits into two supporting legs, forming a “Y”. Combines a lightweight appearance with enhanced load and lateral support. Stylish and futuristic in appearance.

- Applications: Office chairs, task chairs, modern single-seaters, compact tables.

- Production Method:

- Material: Aluminum alloy or shaped steel tubing

- Process: Bending or welding into Y form → Surface finishing (painting, plating, or anodizing) → Foot or caster installation

- Common Equipment: Tube bender, Y-shape jig, anodizing line, flange press

1.13Z-Shaped Legs

- Structure: The silhouette follows a “Z” shape, typically made of three linear segments. Features clean angles and a dynamic appearance with strong design appeal.

- Applications: Contemporary desks, statement coffee tables, display platforms.

- Production Method:

- Material: Aluminum alloy or stainless steel sheets

- Process: Precision bending → Structural welding → Surface treatment (brushed, plated, or painted)

- Common Equipment: CNC bender, angle positioning tools, coating system

1.14Trapezoid Legs

- Structure: Formed by two angled legs of differing lengths connected by a crossbar, creating a trapezoidal frame. Offers strong stability with a modern geometric profile.

- Applications: Dining tables, work desks, industrial benches, and long benches.

- Production Method:

- Material: Carbon steel square or rectangular tubing

- Process: Angle tube cutting → Welded joints → Crossbeam assembly → Surface coating or plating

- Common Equipment: Precision miter saw, welding jig platform, grinding tools, powder coating system

Double Arc Legs

- Structure: Composed of two symmetrically curved metal tubes forming a smooth “S” or “C” shape. The overall design emphasizes fluidity and movement. Aesthetically appealing but structurally complex, making it suitable for high-end designer furniture.

- Typical Applications:

Artistic coffee tables, decorative stands, modern lounge chairs - Manufacturing Method:

- Material Selection: Stainless steel tubing, aluminum tubing

- Process Flow: Precision tube bending → Positioning and joining → TIG welding → Brushed or mirror polishing

- Common Equipment: CNC tube bender, custom clamping fixtures, stainless steel polishing line

1.15Hairpin Legs

- Structure: Made from two or three slender metal rods bent into a U or double-U shape, resembling a hairpin. Lightweight and retro with an industrial vibe, it’s a popular choice among DIY furniture makers.

- Typical Applications:

Coffee tables, side tables, benches, decorative stools, shoe racks - Manufacturing Method:

- Material Selection: Solid round steel, stainless steel rods

- Process Flow: Rod bending → Weld base plate → Edge finishing → Powder coating or blackening treatment

- Common Equipment: Bending jig, MIG welding station, compact paint booth

1.16Arch Legs

- Structure: Legs are designed in a rounded or elliptical arch shape, offering a smooth and elegant visual. The arch design provides both elasticity and structural support, ideal for artistic or custom-made furniture.

- Typical Applications:

Art chairs, round tables, display stands, designer tabletops - Manufacturing Method:

- Material Selection: Stainless steel tubes, aluminum alloy profiles

- Process Flow: CNC tube bending → Laser positioning → Welding and polishing → Brushing or sandblasting and plating

- Common Equipment: CNC bender, laser positioning fixtures, integrated polishing & brushing machines

1.17Bridge Legs

- Structure:Inspired by bridge architecture, these legs feature curved or slanted sides connected by a central horizontal beam. This style offers both structural stability and aesthetic appeal, often seen in large tables.

- Typical Applications:

Dining tables, conference tables, reception desks - Manufacturing Method:

- Material Selection:Large-section square tubes, flat steel, or welded assemblies

- Process Flow:Tube bending or arch welding → Beam reinforcement → Surface coating or brushing

- Common Equipment:Large welding table, forming molds, painting/polishing equipment

1.18Frame Legs

- Structure:Consist of four metal tubes or profiles arranged into a rectangular or trapezoidal frame, resembling a door frame. Offers excellent stability and an industrial look. Optional horizontal bars add visual detail or structural support.

- Typical Applications:

Industrial-style desks, machine tables, shelving frames, workbenches - Manufacturing Method:

- Material Selection:Carbon steel square tubes, rectangular tubes

- Process Flow:Cutting → Frame welding → Grinding → Surface finishing

- Common Equipment:Cut-off saw, welding fixtures, powder coating line

1.19Tripod Legs

- Structure:Three legs arranged in a triangular layout to support a tabletop or seat, offering geometric stability and a light footprint. Suitable for circular or irregularly shaped furniture.

Typical Applications: - Round coffee tables, stools, display units

- Manufacturing Method:

- Material Selection:Solid round bar, stainless steel tube

- Process Flow:Triangular fixture alignment → Welding or bolting → Surface treatment (painting/plating)

- Common Equipment:Tripod positioning jig, welding platform, compact coating station

1.20Pedestal Leg / Center Column

- Structure: A central column supports the tabletop, typically ending in a “cross base” or round base. Compact and space-saving, often used for small round or high-top tables.

- Typical Applications:

Dining round tables, bar counters, meeting tables - Manufacturing Method:

- Material Selection:Large-diameter steel tube with cast iron or steel base

- Process Flow:Tube cutting → Base and flange welding → Coating or plating

- Common Equipment:Automated welding station, base forming machine, electrostatic spray line

Summary Recommendations:

To further categorize these leg styles, consider the following classification dimensions:

- Structural Form: Straight-line, folded-line, framed, pedestal-based, cantilevered

- Design Style: Minimalist, industrial, vintage, Scandinavian, high-end custom

- Manufacturing Complexity:

- Standard Types: Straight, U-shaped, X-shaped

- Custom Styles: Z-shaped, double arc, bridge-type

2.0Common Metal Materials for Table Legs

The choice of metal material for table legs affects not only the structural strength and durability but also the aesthetic style and cost efficiency of the furniture. Different metals offer unique advantages and are suited to various applications and design directions. Below are some commonly used metal materials for table legs:

- Mild Steel (Carbon Steel):

Mild steel is a cost-effective and practical choice with good strength and weldability. It is well-suited for structural table legs such as straight-line or frame-type designs. The surface can be treated with powder coating, painting, or electroplating, achieving finishes ranging from matte black to antique brass. A popular material for industrial and minimalist styles. - Stainless Steel:

Stainless steel provides excellent corrosion resistance and can be finished with brushing, mirror polishing, or sandblasting, offering a sleek, modern look. It’s especially suitable for modern office desks and high-end side tables. While slightly more expensive, it’s ideal for furniture requiring both refined aesthetics and long-term durability. - Aluminum Alloy:

Lightweight and rust-resistant, aluminum alloy is perfect for portable furniture or pieces that are frequently moved. Commonly used in bar tables and laptop desks, it supports anodizing and powder coating with a wide variety of colors, making it a modern and practical choice. - Wrought Iron:

Often used in vintage or European-style furniture, wrought iron allows for handcrafted bending, welding, and decorative finishes such as scrollwork or antique patterns. Though relatively heavy, it provides strong visual appeal and ornamental value. - Chrome-Plated Steel:

Known for its smooth, bright finish and high decorative quality, chrome-plated steel is widely used in modern-style furniture. Though technically a surface treatment for carbon steel or stainless steel, chrome plating is often considered a material in itself due to its aesthetic and wear-resistant properties.

3.0Is Stainless Steel Suitable for Table Legs?

Yes, stainless steel is an excellent material for manufacturing table legs, particularly in modern and high-end furniture designs. Its advantages go beyond appearance, offering outstanding structural performance and long-lasting durability.

- Superior Corrosion Resistance:

Stainless steel is highly resistant to rust and oxidation, maintaining its metallic sheen even in humid environments. This makes it ideal for use in kitchens, bathrooms, balconies, and other moisture-prone areas. - High Structural Stability:

With its high hardness and strong load-bearing capacity, stainless steel is perfect for supporting medium to large-sized tables without the need for additional reinforcements. - Variety of Surface Finishes:

It can be finished with brushing, mirror polishing, sandblasting, or titanium coating. These versatile surface options create a sleek and refined appearance that pairs well with tabletops made of glass, marble, or solid wood. - Easy to Clean and Maintain:

Stainless steel surfaces are smooth and non-porous, making them resistant to dust and grease. Routine cleaning requires only a damp cloth—especially beneficial in commercial spaces or high-traffic areas. - Recommended Applications:

Stainless steel table legs are ideal for office desks, reception counters, side tables, display tables, coffee tables, and outdoor tables—particularly in modern, industrial, minimalist, or contemporary luxury furniture styles.

4.0How to Choose the Best Metal Table Legs for Your Project

When selecting metal table legs for a furniture project, many people instinctively focus on style and appearance. However, structural compatibility is the key to ensuring stability, aesthetics, and long-term durability. The following factors are essential for making an informed and functional choice:

- Tabletop Weight:

The heavier the tabletop, the greater the load-bearing and structural strength required of the table legs. For example, solid wood tops, marble slabs, and tempered glass panels are dense and heavy materials that are not suitable for lightweight designs such as hairpin legs or slender pedestal structures. Instead, consider using carbon steel frame legs, H-shaped legs, or integrated U-shaped structures to ensure long-term stability without wobbling or deformation. - Tabletop Material:

Different tabletop materials require compatible leg structures and mounting solutions. For instance:- Solid Wood Tops:Best paired with square tube legs or tapered legs featuring welded mounting plates, allowing for direct screw installation.

- Glass Tops:Require legs with suction pads or fixed brackets. Stainless steel is recommended for its clean appearance and fingerprint resistance.

- Marble Tops:With a high center of gravity and smooth surface, they benefit from wide bases or A-frame legs combined with anti-slip pads to enhance overall stability.

- Tabletop Size & Shape:

Large tabletops (e.g., over 2 meters in length or circular designs) need well-distributed leg placements to prevent sagging. Structures like frame-type, double-U, or X-shaped legs are ideal for added support. In contrast, small side tables or single-person desks can be sufficiently supported with round legs, tapered legs, or center-column designs. - Leg Angle & Geometry:

Whether table legs are installed vertically or angled (e.g., V-shaped, trapezoidal), the design significantly impacts both stability and space efficiency. For example:- Straight or U-shaped Legs:Great for wall placement and space-saving.

- Angled or V-shaped Legs:Provide a wider support base with a visually lighter feel, yet remain sturdy.

- X-shaped or Trapezoidal Legs:Ideal for tables with higher centers of gravity or anti-tip requirements, offering better torsional resistance.

- Overall Style & Budget Considerations:

Functionality doesn’t have to compromise style. Once structural needs are met, you can choose appropriate surface finishes—such as black sandblasted steel, mirror-polished stainless steel, or electroplated brass—to achieve modern, vintage, minimalist, or industrial aesthetics. Keep in mind that different materials and finishing processes will directly influence your budget.