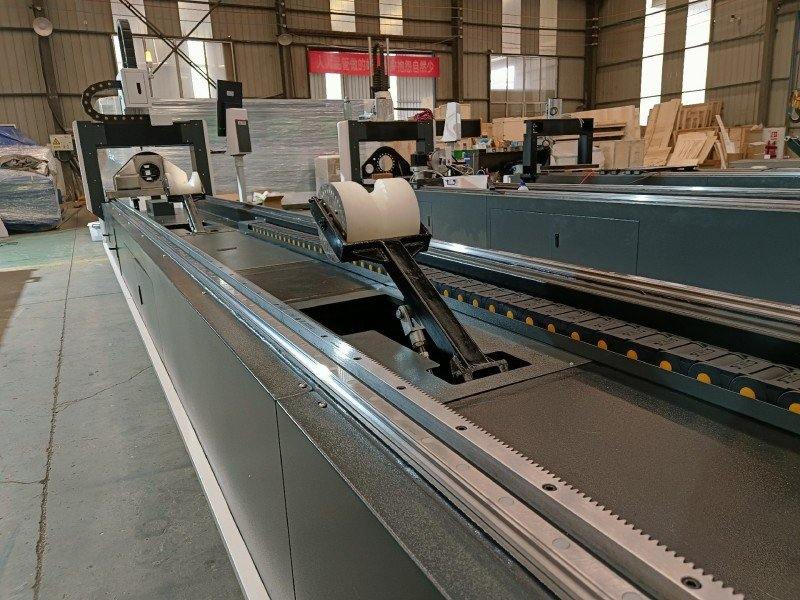

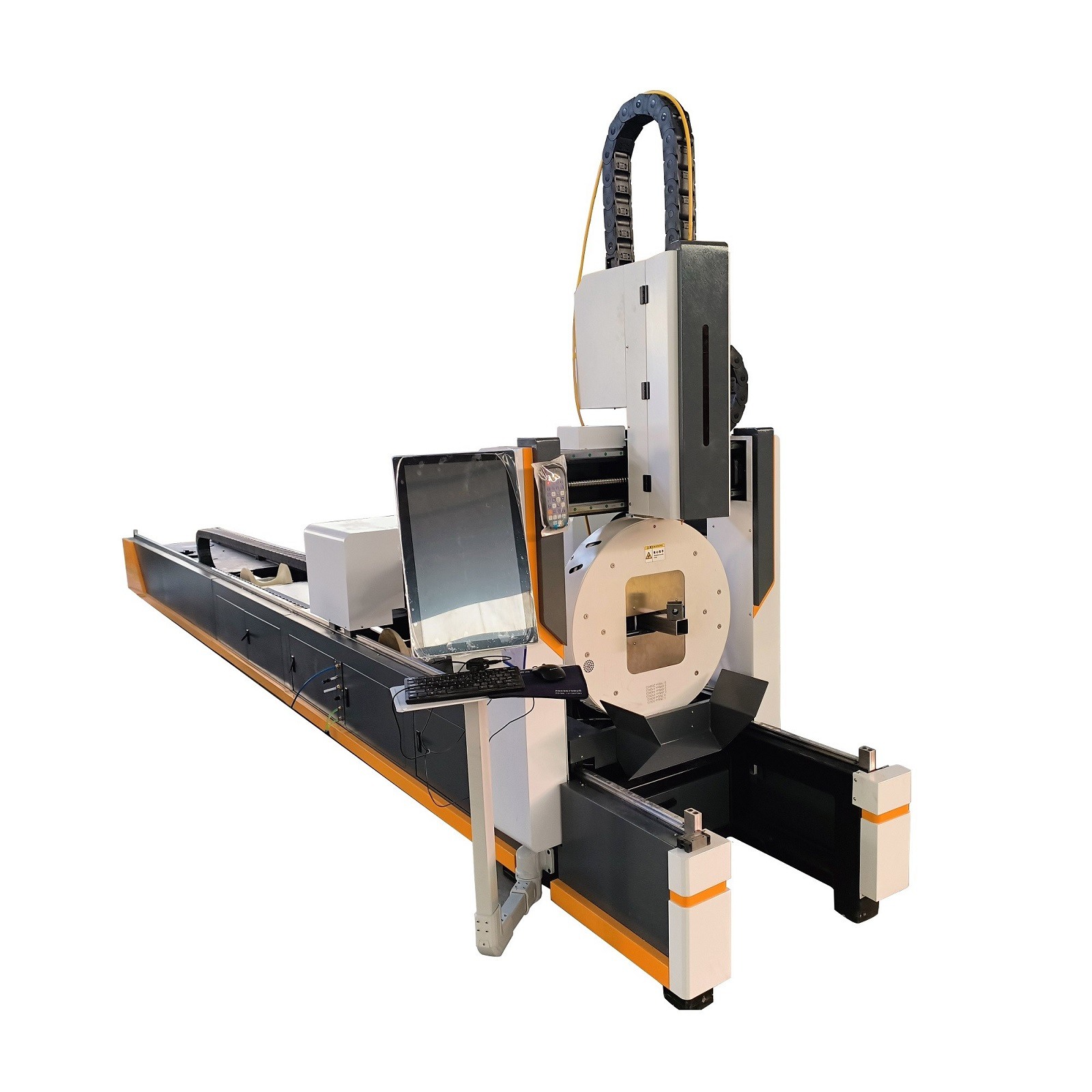

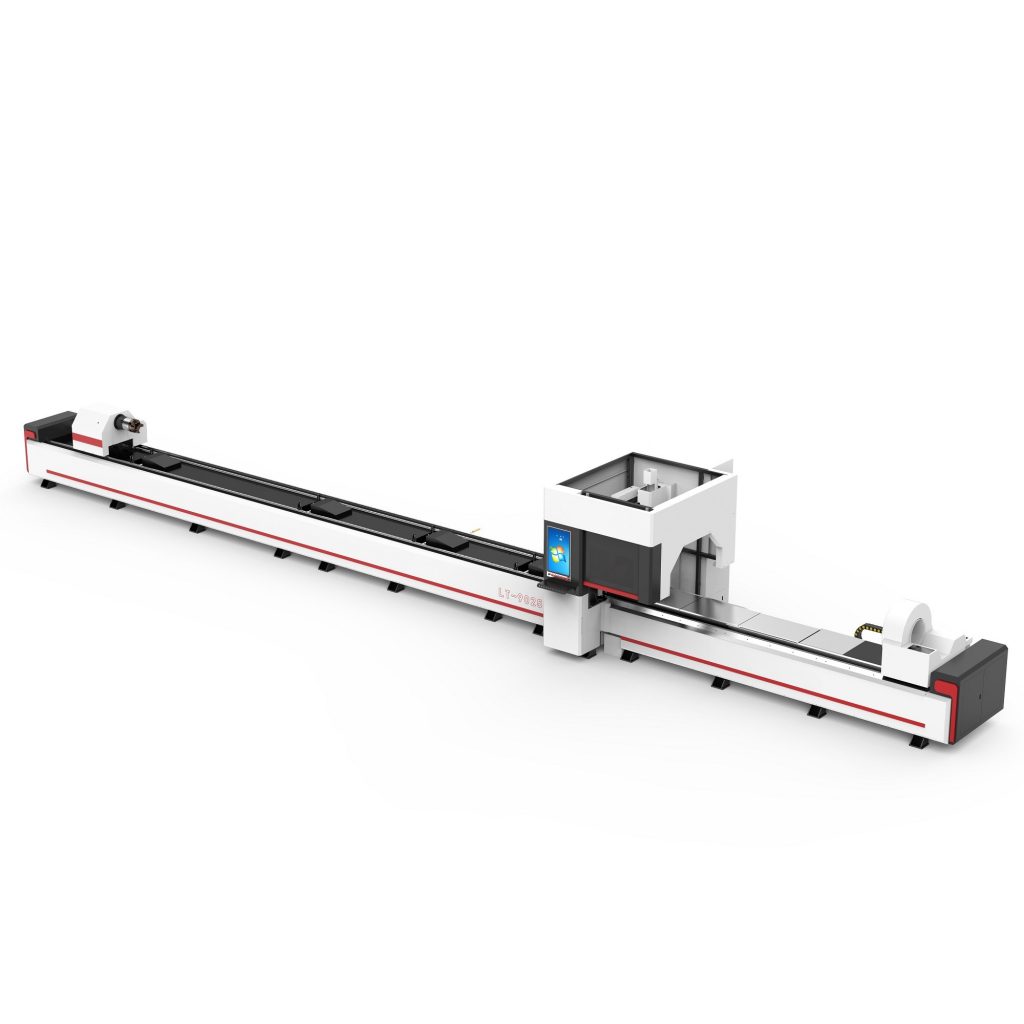

Product Introduction – Fiber Laser Tube Cutting Machine

- Supports direct 3D drawing import and automatic path recognition

- High-speed and high-precision cutting

- Optional full-automatic loading system

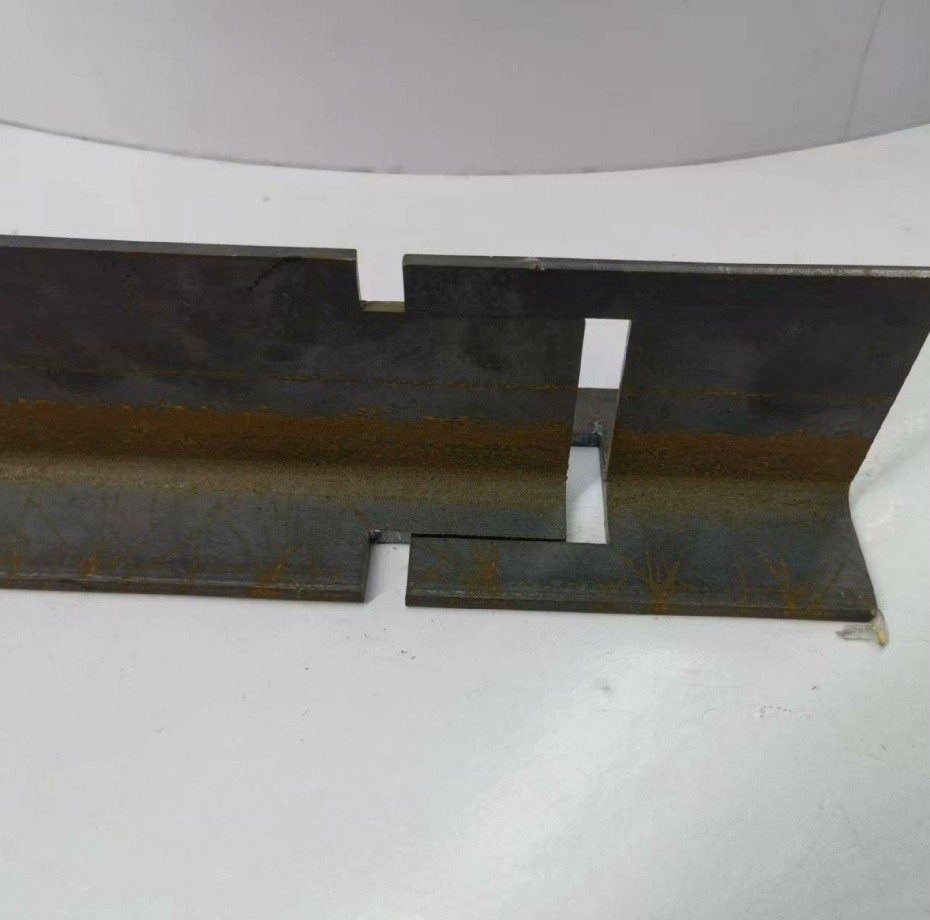

- Smooth cutting edges, no burrs or burn marks

- Excellent dimensional consistency across identical parts

- Compatible with various laser power levels for different wall thicknesses

Product Features

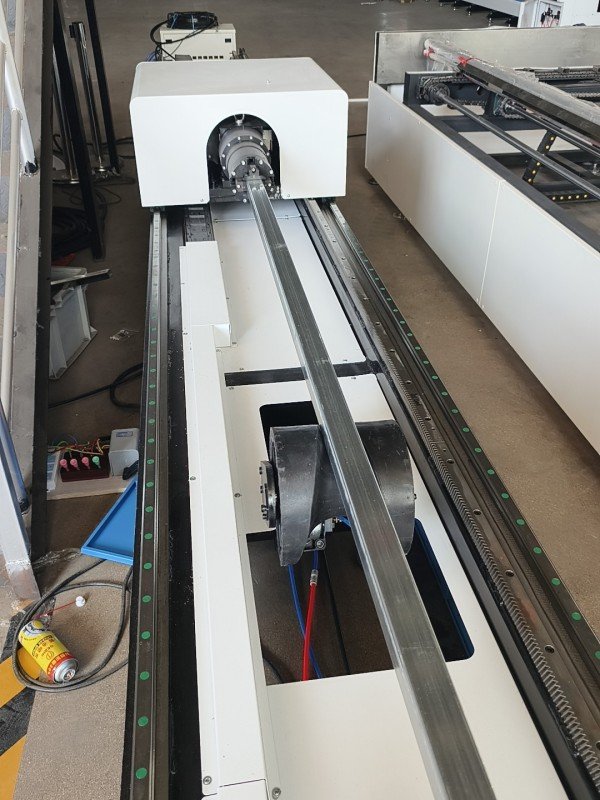

- Rear-end loading system: simple operation, labor-saving, enhanced safety

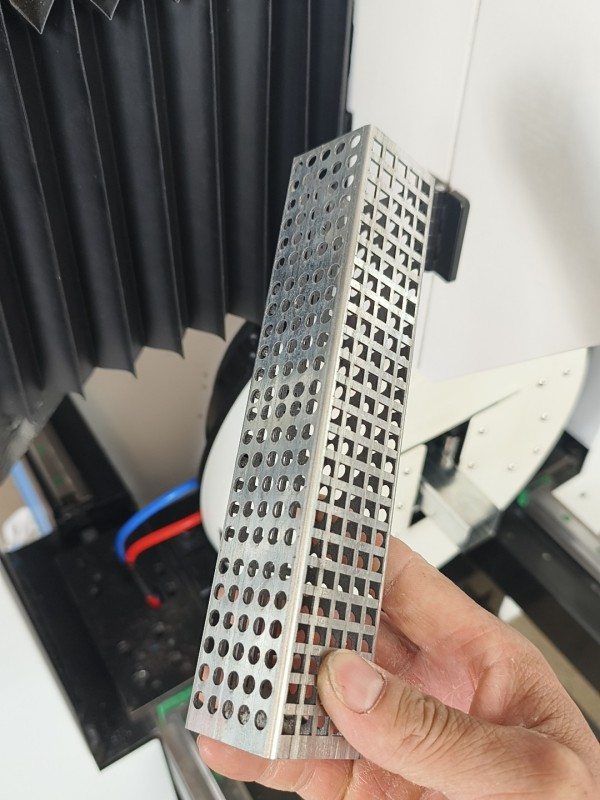

- Capable of hole cutting, slotting, trimming, and complex pattern processing

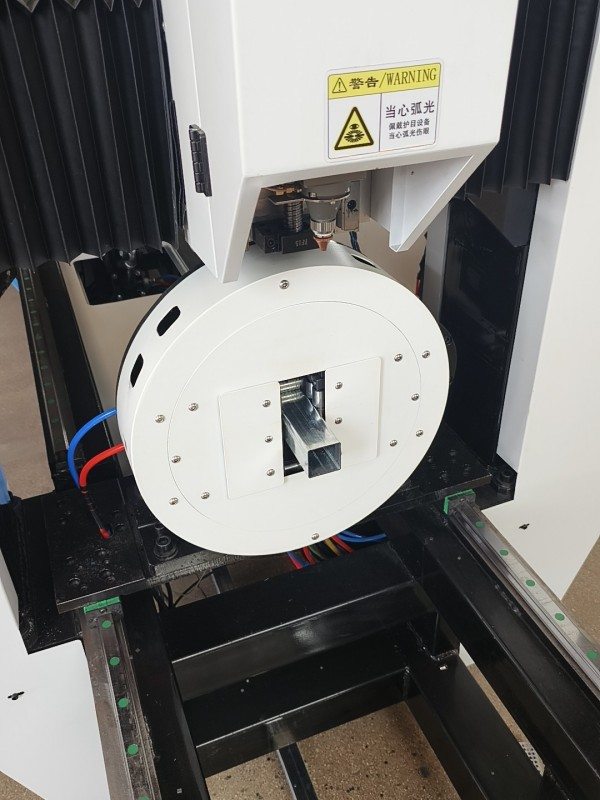

- Five-axis, four-linkage integrated cutting system with fast dynamic response

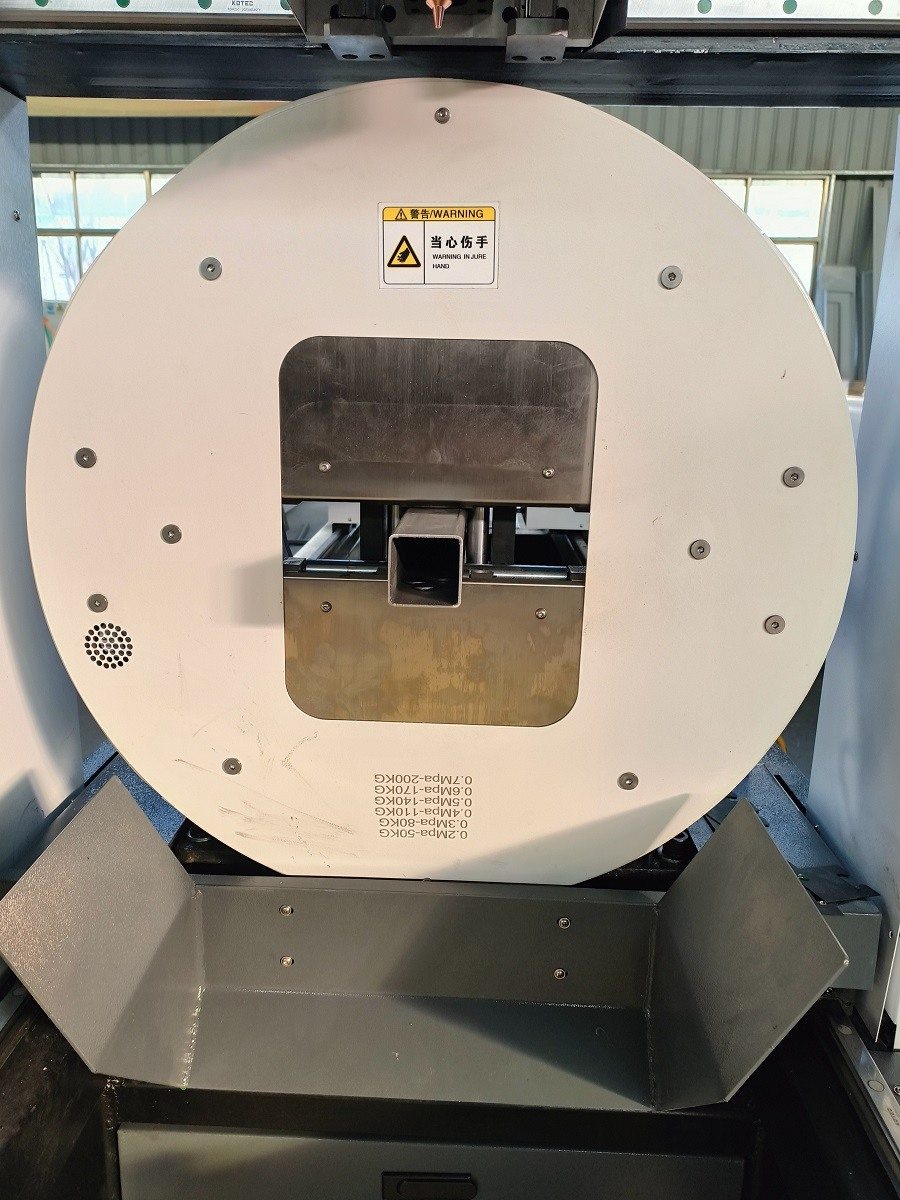

- Fully-through CNC rotary chuck, supports tube diameter up to 145mm

- Reciprocating feeding system supports spliced cutting for oversized graphics

Product Advantages

- Small heat-affected zone, minimal deformation

- Cutting speed over 100× faster than wire cutting

- Low operating cost – only 1/8 to 1/10 of similar CO₂ laser cutters

- High cost-efficiency – 1/3 the price of CO₂ lasers, 2/5 of CNC punch machines

- High precision – accuracy up to 0.03–05 mm, 50% better than CO₂ laser cutters

- Uses fiber laser source – currently the most stable and efficient laser technology

Key Features of the Fiber Laser Tube Cutting Machine

Cutting Capabilities

- Cuts round pipes, square pipes, channel steel, angle steel, and H-beams

- Supports chamfering and cross-border cutting (gantry moves beyond limit for tail-saving)

- Max clamping pipe outer diameter: Φ1000mm; max load: 6 tons

- Chuck diameter range: 220–600mm, customizable beyond 600mm

Control System

- 21″ high-resolution LCD display shows cutting paths and graphics

- Simple keyboard control with USB file transfer and manual program editing

- Built-in 4G storage; supports fast, efficient data access

- Built-in pipe cutting library for auto-generation of processing records and reports

Automation & Precision

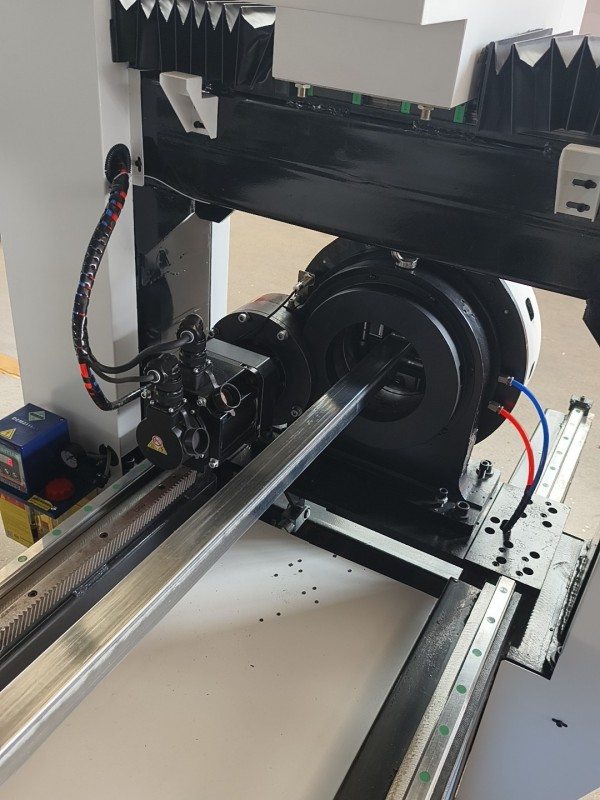

- Dual-chuck system for stable support of heavy tubes

- Self-centering chuck automatically adapts to various tube shapes (round, square, U-profile, channel, I-beam, etc.)

- Servo motor-driven system for high speed, precision, and smooth operation

- Movable crossbeam and intelligent trailer prevent tube sagging

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.