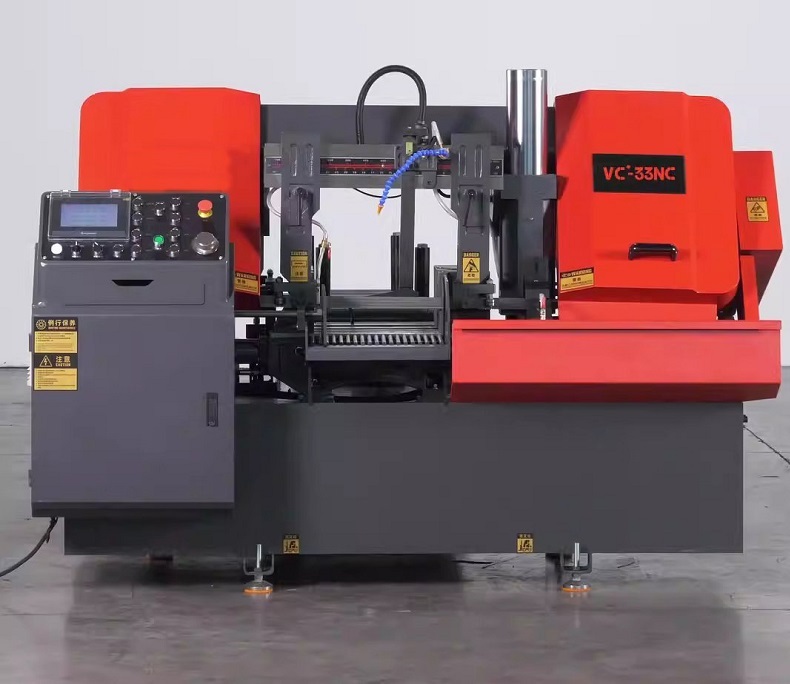

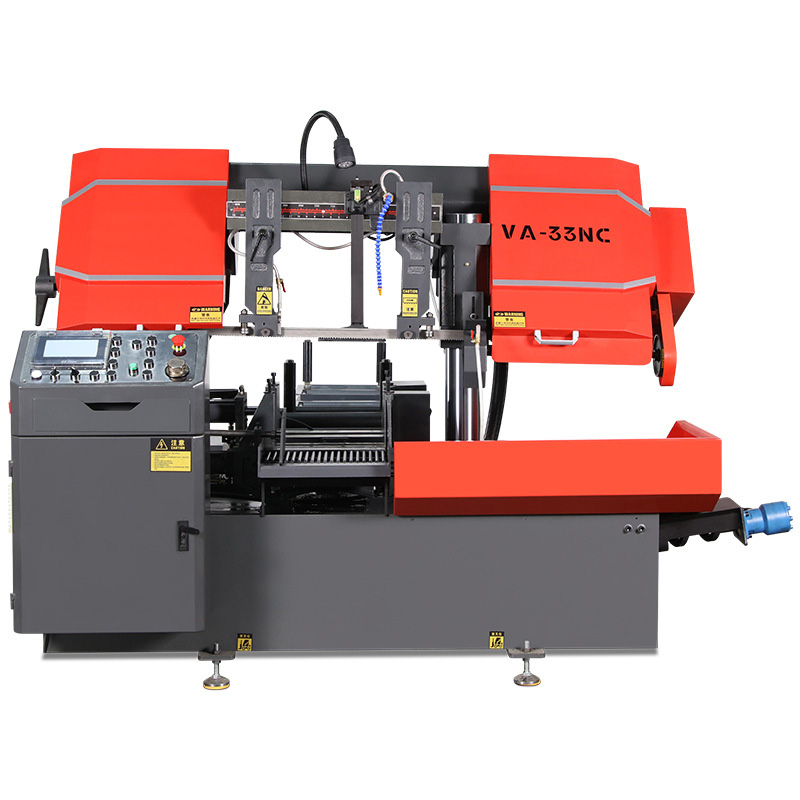

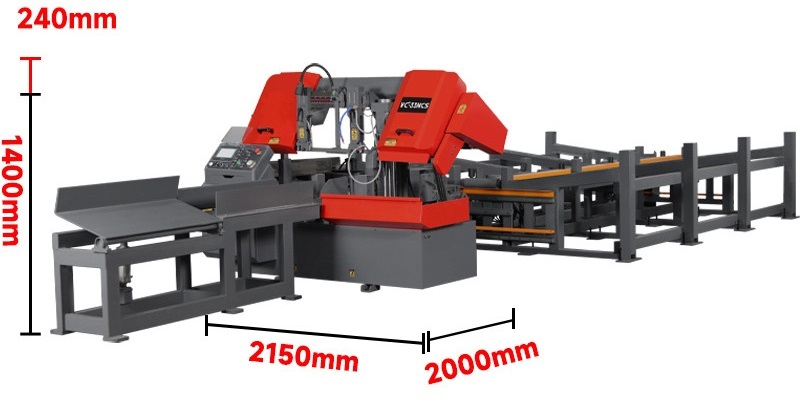

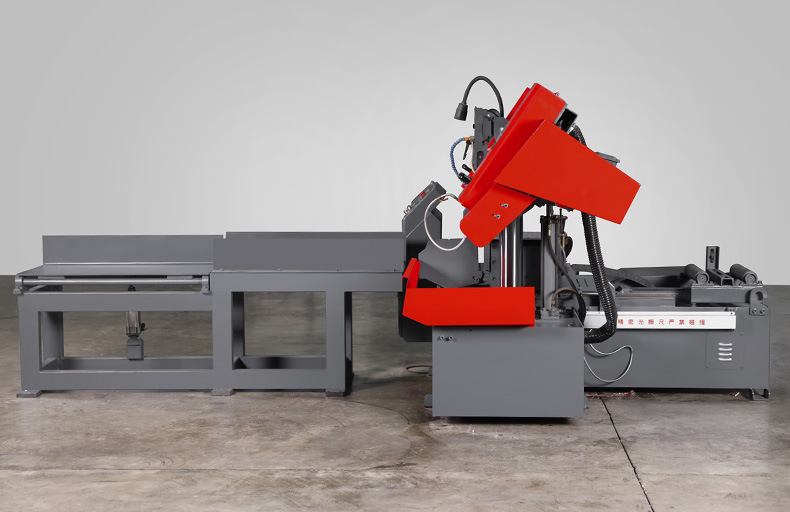

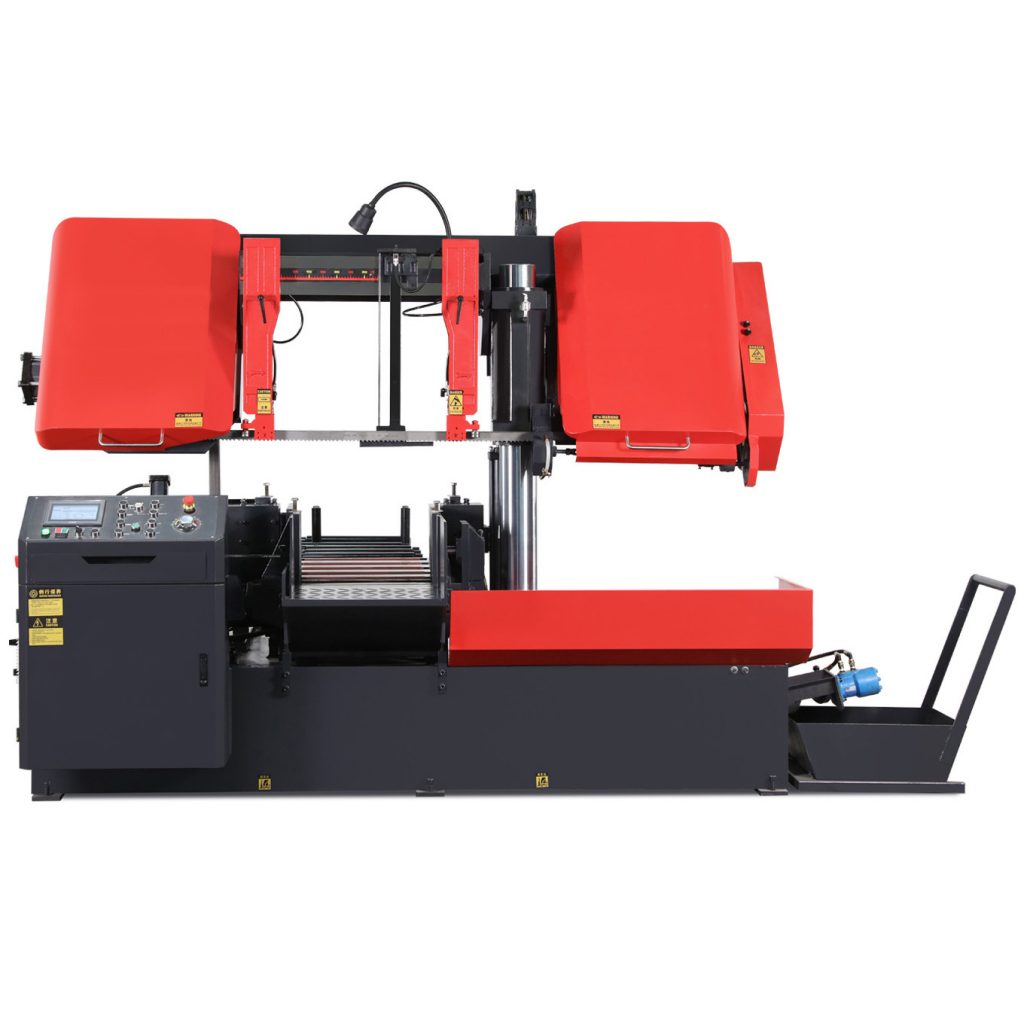

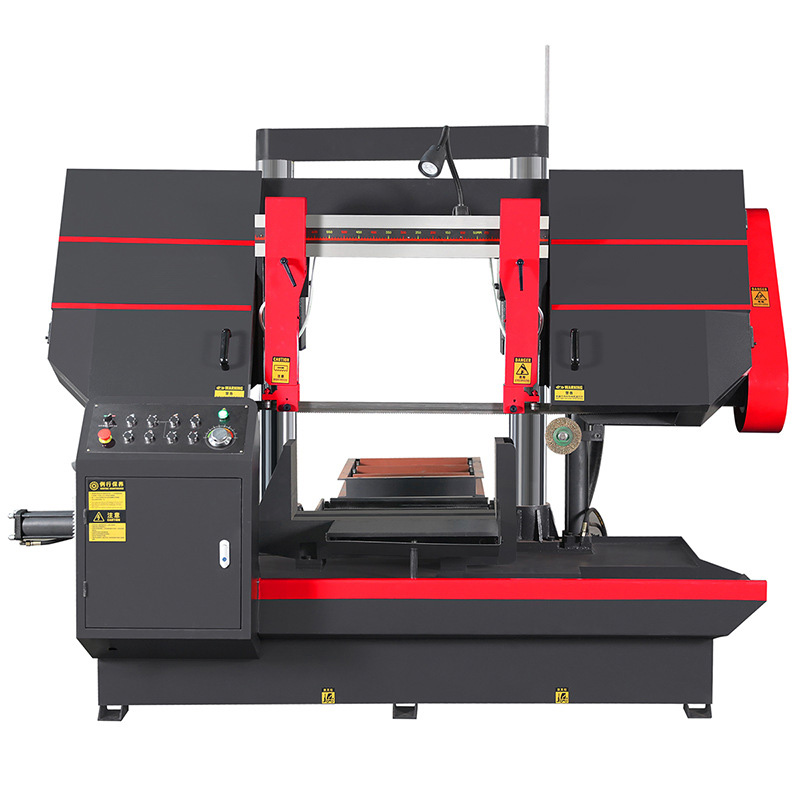

The AEK-VA-33NC is built on a rigid cast-iron frame with full-stroke hydraulic cylinders and a servo-driven feed mechanism, minimizing vibration and ensuring a straight feeding path for precise cutting. The saw also features a hydraulic chip conveyor, cooling system, and automatic clamping, providing stable operation and reducing maintenance during long-term use.

Custom-Built on Demand

Key Features:

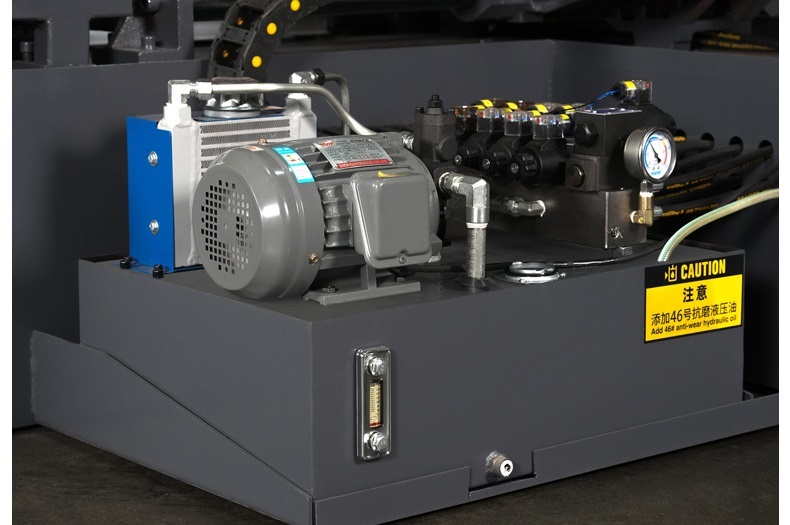

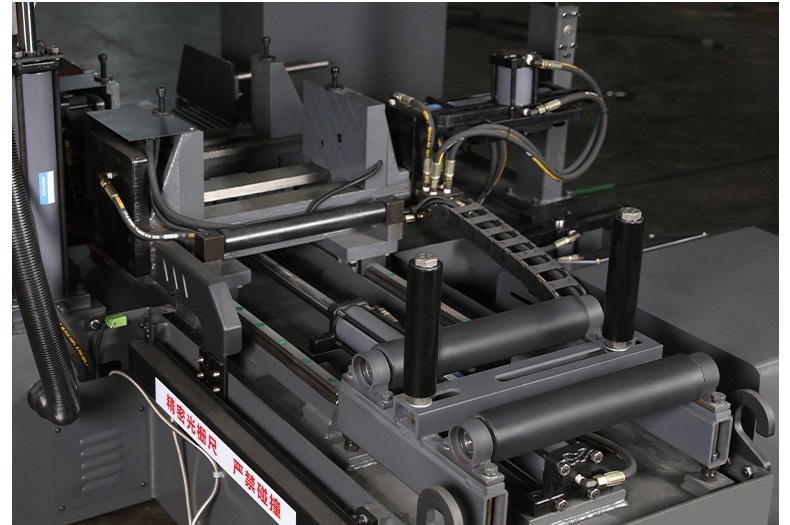

- Efficient Heat Dissipation: Built-in air-cooling structure controls oil temperature, prevents hydraulic overheating, and ensures stable long-term performance.

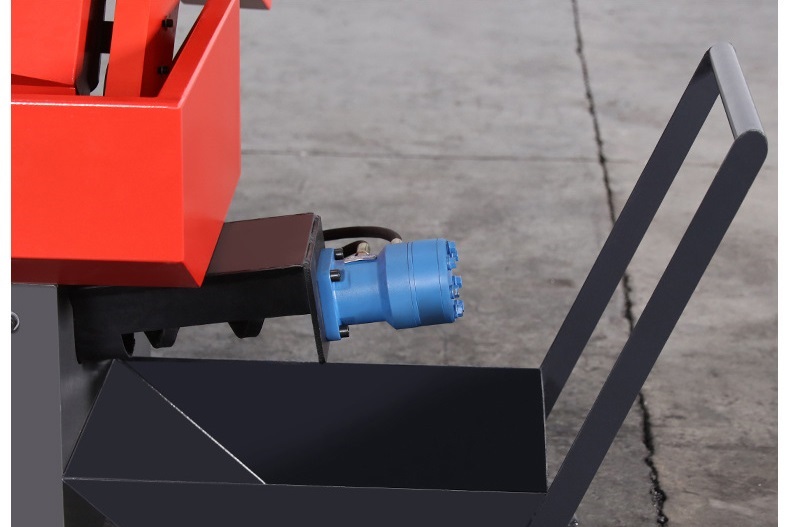

- Convenient Clamping: Full-stroke hydraulic clamping cylinder with one-button operation simplifies the process, reduces manual intervention, and improves consistency.

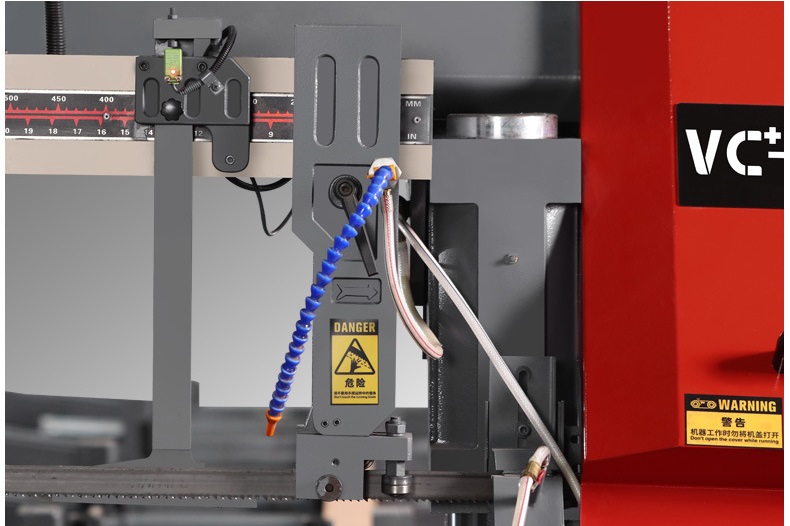

- Accurate Feeding: Hydraulic guide rail positioning keeps the feeding path straight, enhancing cutting accuracy and reducing material waste.

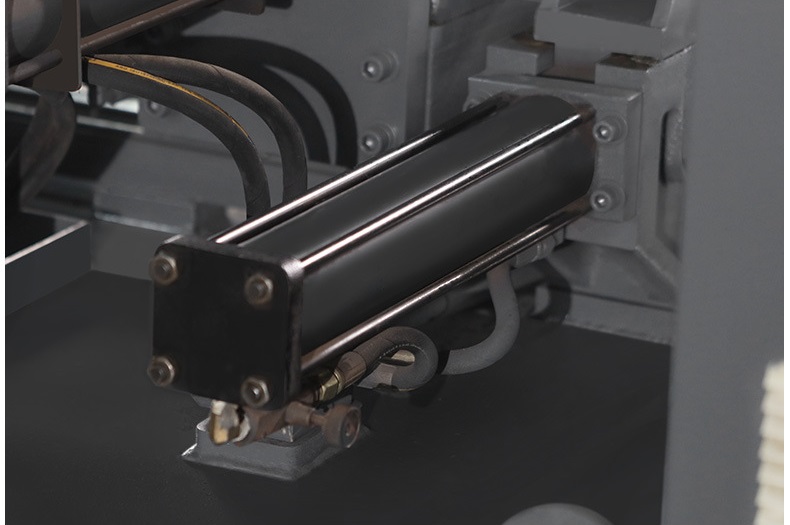

- Smooth Chip Removal: Hydraulic spiral chip conveyor with adjustable speed maintains a clean and unobstructed work area.

- Powerful Motor: Three-phase 4 kW copper motor provides continuous, stable power for high-intensity, heavy-load cutting.

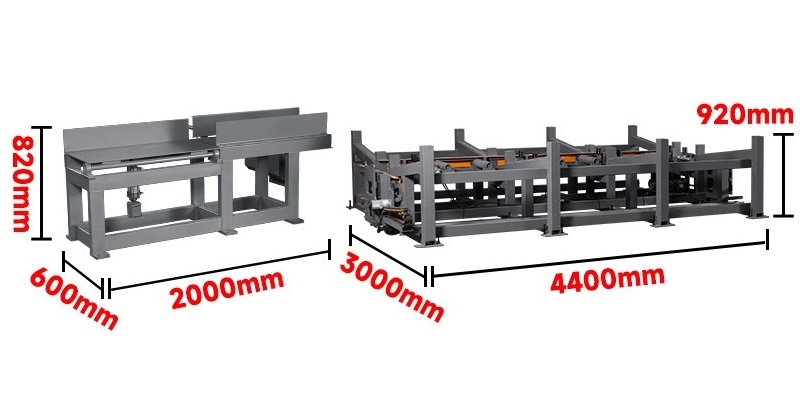

- Solid Receiving Platform: Thickened bevel platform supports long or heavy materials, improving operational safety and efficiency.

- Stable Guide: Pure cast-iron one-piece guide arm ensures low vibration and smooth saw band operation.

- Easy Installation: Built-in leveling screws allow quick on-site setup without foundation fixing.

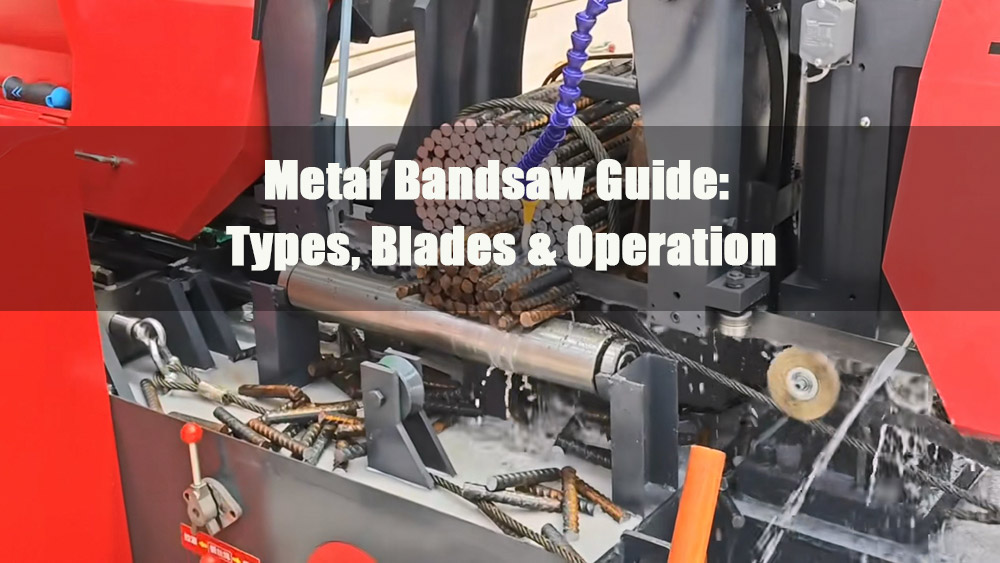

Applications:

The AEK-VA-33NC series is suitable for metalworking industries including machinery manufacturing, automotive parts, steel service centers, and batch metal cutting. With intelligent control, robust structure, and reliable long-term operation, it significantly improves production efficiency, reduces labor costs, and minimizes maintenance, making it an ideal choice for both small workshops and large manufacturing enterprises.

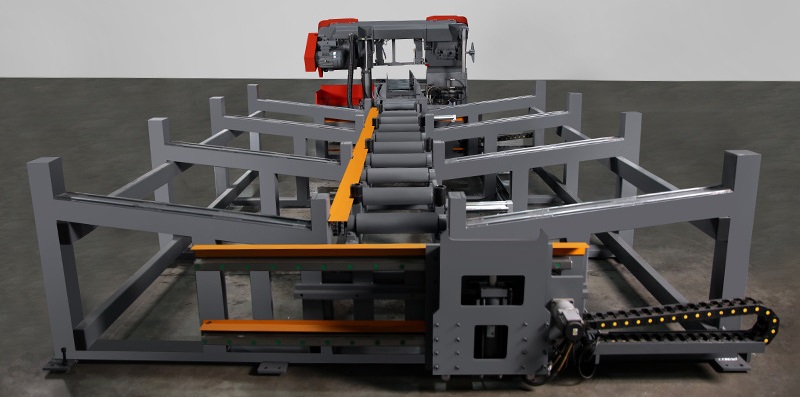

NC Band Saw Production Line Configuration

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.